To Purchasers: From a Simple Reactive Power Compensation Solution to a Comprehensive "Power Quality Service Provider", What Capabilities Should a Reliable Low-Voltage Reactive Power Compensation Equipment Manufacturer Possess?

In today's industrial environment where power applications are becoming increasingly complex, power quality has become a crucial factor affecting production efficiency, equipment safety, and energy costs. In the past, the main purpose of your purchase of low-voltage reactive power compensation equipment might have been merely to meet the assessment requirements of the power supply department regarding power factor. However, with the widespread use of non-linear loads such as frequency converters and rectifier equipment, problems like harmonic pollution, voltage fluctuations, and three-phase imbalance in the power grid have become increasingly prominent. At this point, if your partner can only provide a single reactive power compensation solution, it is like providing only a fever-reducing medicine to a patient with a high fever without addressing the source of the infection that causes the fever. A reliable equipment manufacturer must make the transition from being a "reactive power compensation equipment supplier" to a comprehensive "power quality service provider", which requires the manufacturer to possess multi-dimensional comprehensive capabilities.

Precise Diagnosis and System Analysis

Before prescribing a treatment plan, an excellent doctor must be proficient in diagnosis, and the same is true for a reliable manufacturer of low-voltage reactive power compensation equipment that provides power quality management services. A reliable partner should first be an outstanding "power grid doctor" who not only sells reactive power compensation products but also offers professional on-site power quality testing and in-depth data analysis services. Through advanced power quality analyzers, a qualified power quality service provider should be able to accurately capture the harmonic spectrum in the power grid, voltage sags, flicker, and real-time changes in power factor. More importantly, a qualified power quality service provider must also have the ability to interpret data, being able to identify whether the problem root is from a certain variable frequency drive equipment, an arc furnace in the process, or a design defect of the entire distribution system. This precise diagnostic ability is the first step in transforming standardized products into personalized solutions and is the fundamental prerequisite for maximizing the governance effect. If your partner lacks this ability, all subsequent reactive power compensation plans will be like groping in the dark, unable to eliminate the root cause.

Technical Selection and Solution Design

In the face of complex power quality issues, a single technical approach often falls short. Harmonic control, reactive power compensation, voltage support - these urgent needs often intertwine. Therefore, a reliable power quality service provider that you can trust must possess a diversified technical arsenal and have a systematic engineering mindset for integrating all these technical tools. This means that an outstanding power quality service provider not only needs to be proficient in traditional low-voltage reactive power compensation technologies, but also deeply understand the working principles and application boundaries of power electronic technologies such as active power filters (APF) and static var generators (SVG). In actual projects, the service provider needs to make precise technical selection and solution design based on the diagnostic results. For example, in cases of severe harmonics, merely investing in traditional capacitor-reactor groups may lead to resonance risks. At this time, it is necessary to consider adopting a detuned filtering solution or directly introducing an active power filter. In scenarios with rapid load fluctuations, the dynamic response capability of thyristor switching switches or SVG becomes a must. This objective and neutral solution design capability based on actual needs rather than a single product line is the key criterion that distinguishes ordinary low-voltage reactive power compensation equipment manufacturers from true solution providers.

R&D and Manufacturing Ability

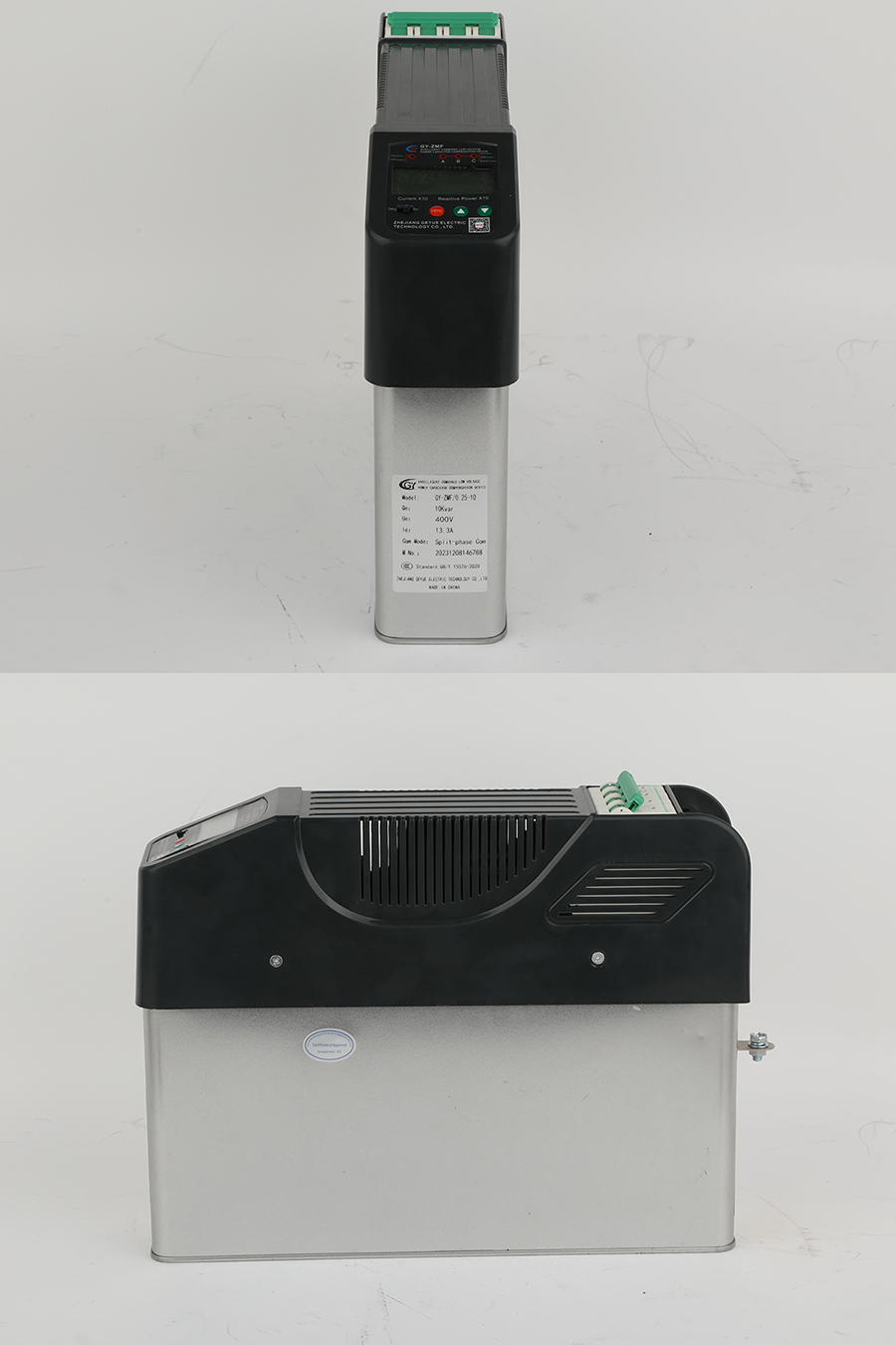

No matter how perfect the solution may seem on the surface, it ultimately requires high-quality and efficient hardware equipment to be implemented. Therefore, when you consider the solution, do not forget that the product strength of the solution provider is of vital importance, which is a manifestation of their profound research and manufacturing capabilities. At the core component level, the solution provider (who is also the equipment manufacturer) has a profound understanding of capacitors and reactors, which is the foundation for the successful implementation of the solution. For example, high-performance metallized film capacitors have superior anti-overflow current ability and lifespan compared to ordinary products, while the linearity and anti-saturation ability of reactors directly determine the stability in a harmonic environment. At the whole machine level, from the structural design of the main circuit, the optimized layout of busbars, to the scientific planning of the cooling air ducts, every detail affects the long-term reliability of the equipment. More importantly, with the popularization of industrial Internet of Things, equipment manufacturers also need to possess the ability to combine software and hardware for development, so that their products can be equipped with intelligent monitoring and remote operation functions, shifting from passive maintenance to proactive prevention. This integrated research and manufacturing system covering core components, whole machine design, and intelligence is the core guarantee for a reliable final governance effect provided by a trustworthy power quality service provider.

Full Life-Cycle Services and a Continuously Win-Win Partnership

Therefore, an outstanding power quality service provider must be able to offer you service support throughout the entire lifecycle of the equipment, starting from the professional consultation and scheme design in the project's early stage, continuing through the technical guidance during the installation and commissioning phase, and extending to the operation and maintenance period lasting for ten years or even longer. Moreover, your service provider should also be able to offer prompt spare parts response, regular equipment health checks, and professional fault diagnosis. Especially in this digital age, such maintenance services should be upgraded to remote monitoring and early warning services based on cloud platforms. By using real-time data, they can understand the status of low-voltage reactive power compensation equipment and prevent faults before they occur. This attitude of integrating one's own interests with the long-term operational benefits of the customers marks a complete transformation from a "transactional supplier" to a "fate partnership partner".

At Geyue Electric, we have long regarded "a comprehensive provider of power quality services" as our strategic positioning for development. We not only offer a complete product line covering from low-voltage reactive power compensation to active filtering, but also have established an all-round capability system ranging from on-site diagnosis, scheme design, intelligent manufacturing to full life cycle services. Our CJ19 series capacitor switchover contactors, with their outstanding current-limiting technology and mechanical stability, have become the core execution units in many customers' compensation cabinets, and this is merely a reflection of our technical strength. We understand that customers' trust stems from our reliable ability to solve problems. Geyue Electric looks forward to becoming your reliable partner in power quality, with a comprehensive technical perspective, reliable product quality and continuous services, to jointly safeguard the purity and efficiency of your power grid and lay a solid energy foundation for your green intelligent manufacturing path. If you want to talk to our professional technical engineer, please send your inquiry to info@gyele.com.cn.

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?