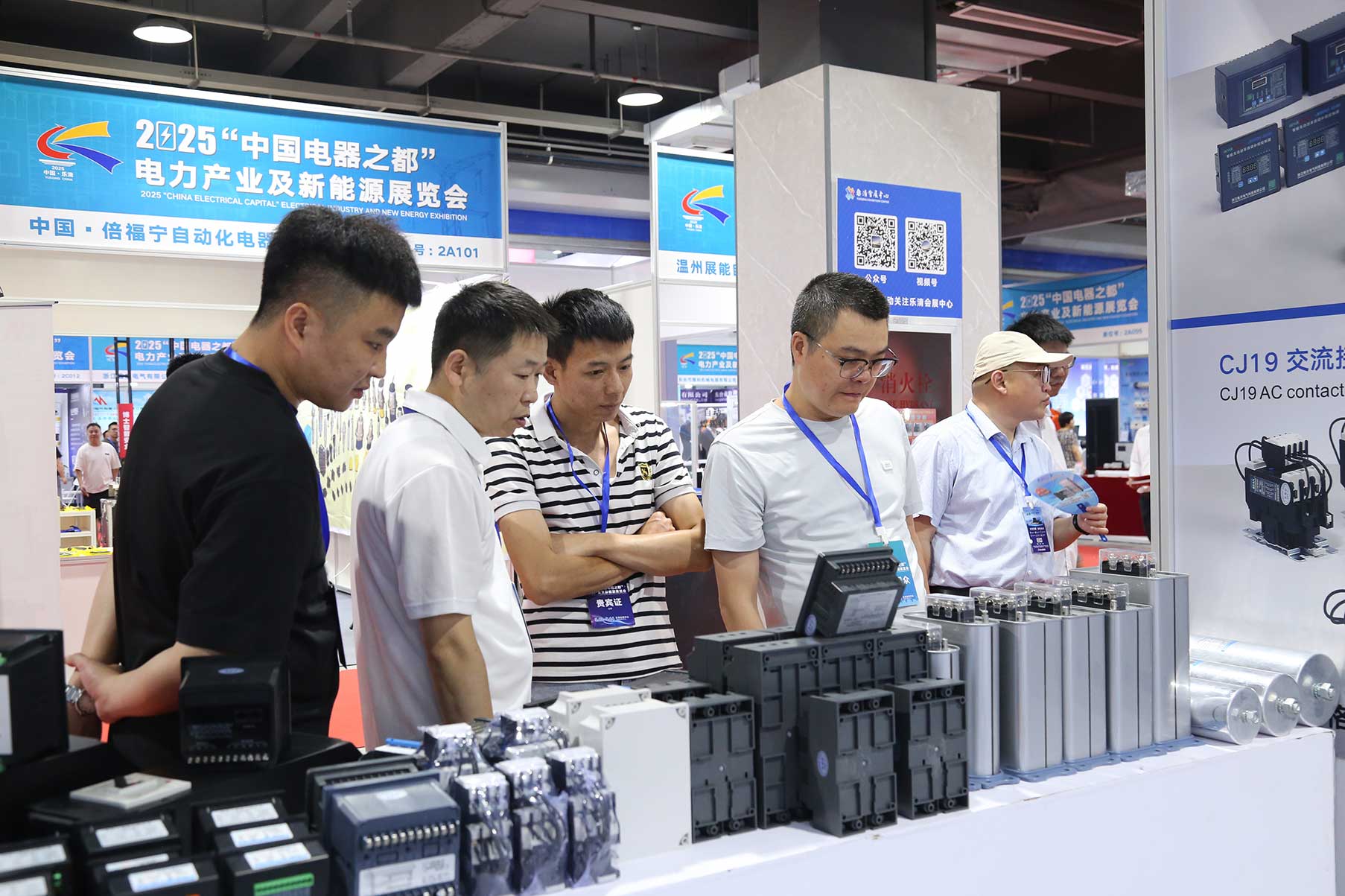

Why do customers trust us and continue to cooperate with us? Let’s talk about today’s reactor delivery

Preface

This morning, in the delivery area of the Wenzhou production base, 1,000 CKDG series low-voltage series reactors were loaded into standard export wooden boxes and set off for Ningbo Port. This batch of equipment will be shipped to the Thai Group Industrial Park for the harmonic control project of the reactive compensation cabinet of its power distribution system. This customer has purchased 90 orders of our reactors since 2018, and has placed orders almost every month. It took only 120 hours from signing to delivery of this order. In the Southeast Asian market, we have maintained a customer repurchase rate of more than 91% for five consecutive years, and the equipment operation failure rate has remained stable at 0.01%.

Technical Positioning of Reactors

As the core component of the reactive power compensation system, the low-voltage series reactors undertakes the key functions of suppressing harmonics and stabilizing the power grid. The CKDG series products adopt a fully enclosed iron core structure with a rated capacity of 80 kvar. In a 400V distribution network, the device can absorb more than 31% of the 5th and 7th characteristic harmonic currents, compressing the system's total harmonic distortion rate from 35% to within the 5% safety threshold. The winding adopts H-class insulation material to ensure continuous operation in a high temperature environment of 180°C. The core lamination accuracy is controlled within a tolerance band of 0.02 mm to ensure that the magnetic flux is not saturated under 150% overload conditions. The tropical special model has passed the 2000-hour salt spray test and has a life cycle of 120,000 hours in a 40-degree Celsius 95% humidity environment.

The Quality System Builds the Foundation of Trust

The quality control system we have established runs through the entire life cycle of the product. On the raw material side, we use a spectrometer imported from Germany to conduct 100% testing on each roll of silicon steel sheet to ensure that the iron loss value is stably controlled below 1.75W/kg (the industry average is 2.3W/kg). In the winding process, we use a servo tension system with a precision of 0.3% to ensure that the gap between coil layers is ≤0.15 mm. Each finished product must pass the 24-hour full-load temperature rise test designed by us, and the temperature data of key nodes is uploaded to the self-developed cloud platform in real time. It is this rigorous system that supports the excellent record of 0.008% failure rate in the delivery of 9,200 equipment in Southeast Asia in three years. After 35,000 hours of operation of the 680 pcs series reactors purchased by Chalathai Group in 2019, we detected that the inductance decay was only 0.28%, and the insulation resistance remained above 18GΩ-these data confirm the credibility of our quality commitment.

Analysis of Manufacturing Technology Advantages

The production base is equipped with eight fully automatic production lines, achieving three core technological breakthroughs. The winding robot arm completes the precise arrangement of 42 meters of copper wire per minute, and the production time of a single coil is 37 seconds. The five-axis laser cutting system achieves 0.02 mm cutting accuracy of silicon steel sheets, and the material utilization rate reaches 96%. The modular design supports switching product specifications within fifteen minutes, and the standard wooden box packaging system is suitable for the full range of 7-800 kvar products.

Efficient Delivery Capability Demonstration

The 120-hour delivery cycle of this Thai order is due to the efficient operation system of factory direct delivery. We automatically decompose order requirements through the intelligent manufacturing system, and the raw material inventory and suppliers are linked in real time to achieve precise material preparation. The production line has the ability to produce mixed flows of multiple specifications, and the time required to switch product specifications has been reduced from the traditional four hours to fifteen minutes. The logistics link adopts a standardized packaging solution, and the wooden box shockproof module assembly is completed in advance, which increases the loading efficiency by three times. Taking the urgent order of a Chilean customer last Thursday as an example, we achieved 28-hour cross-border delivery from the factory by optimizing the pre-examination of customs clearance materials and the coordination of exclusive flights. Data from the past three years show that the factory direct delivery model has maintained a 100% on-time delivery rate for orders, and the response speed for urgent orders has increased by 67% compared with the industry average.

Full-cycle Service Guarantee

The pragmatic service system built by our Geyue Electric always takes customer needs as the core, and ensures the stable operation of equipment through a three-level response mechanism. When the series reactors is abnormal, we promise that domestic customers will have technicians arrive at the site within 48 hours. The independently developed remote diagnosis platform uses AES-256 encrypted channels to transmit real-time data, achieving 98% fault location accuracy. Last year, a chemical plant in Jiangsu used this platform to remotely guide the replacement of temperature sensors, and only spent 320 yuan to avoid the loss of returning the whole machine to the factory. The factory has 300 standard models in stock and establishes a "faulty parts return to the factory for inspection + synchronous replacement of new products" mechanism: when the customer sends back the faulty parts, we immediately send out the same specification equipment and track it with GPS throughout the process, and the average replacement cycle is controlled within 3.5 days. For tropical high humidity environments, we provide insulation resistance test guides and special test fixtures free of charge, and regularly push maintenance points. All equipment enjoys a one-year whole machine warranty and lifelong technical support. This commitment has been implemented for seven years. An analysis report will be issued 24 hours after the faulty parts are returned to the factory, and the repaired equipment will be transferred to spare inventory, forming a closed-loop resource utilization system. In the over-temperature alarm case of the Zhejiang Textile Factory in August last year, it took only 44 hours from remote diagnosis to spare parts replacement, saving 98% of the cost compared to returning the entire machine to the factory. This is a real proof of the value of our service.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.