Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

In a low-voltage power distribution system, reactive power compensation is akin to a precise balancing art, and the configuration of the compensation capacity is the center of this art. Many customers often find themselves in a classic dilemma during the planning stage: Should they over-configure to be on the safe side, with the mentality of "Better Safe Than Sorry", or should they take the time to pursue the "Precise Calculation" that is just right? Geyue Electric, as a pioneer in the field of low voltage reactive power compensation, we hope to have an in-depth discussion with you on which strategy can bring you the most long-term stability and the most practical benefits.

The Gains and Losses of the Traditional Strategy of "Better Larger Than Smaller"

The concept of "Better Larger Than Smaller" for the configuration of reactive power compensation capacity was quite prevalent in past industrial construction. The underlying logic is straightforward: by allocating a larger compensation capacity, it is as if a spacious protective suit is donned for the power system, ensuring that it can cover any potential future inductive loads, thus avoiding power factor non-compliance due to insufficient capacity and preventing penalties from the power company.

However, Geyue Electric believes that this overly simplistic strategy actually has some unforeseen hidden costs, the scale of which is far beyond the imagination of many people. An excessively large compensation capacity can easily push the system to another dangerous edge - overcompensation. When reactive inductive power exceeds the reactive demand of capacitive power, the system voltage will rise abnormally, which is equivalent to a continuous voltage shock for motors, transformers and various precision electrical equipment, accelerating their insulation aging and shortening their service life. What's more troublesome is that in light-load conditions, excessive capacitor banks being put into use may trigger dangerous resonance phenomena, not only failing to improve power quality but also amplifying harmonics in the power grid, and in severe cases, even causing equipment damage and system paralysis. Moreover, a one-time huge investment in capacitors also means higher initial procurement costs, larger installation space and more useless power losses in future operation. "Better Larger Than Smaller" is like equipping a family car with a huge fuel tank. This may seem like a one-time solution, but in reality, it is extremely troublesome, resource-intensive, and fraught with significant risks.

The Rational Light of Modern Engineering: Precise Calculation

Compared to the empiricism of "Better Larger Than Smaller", precise calculation represents the rationality and refinement of modern power engineering. It is not a simple instantaneous measurement, but a dynamic and systematic diagnostic process. Its core lies in accurately capturing the real pulse of reactive power demand in the power system.

The first step in precise calculation is in-depth data collection and analysis. As your expert in low-voltage reactive power compensation, the first thing Geyue Electric needs to do is to examine the nameplate data of all your inductive loads, including motors, transformers, reactors, etc., to calculate their natural power factor. More importantly, we must conduct on-site power quality measurements, using professional power quality analyzers, to record the dynamic change curves of active power, reactive power and power factor of the system over a day, a week, or even a production cycle. This curve graph is the "electrocardiogram" of the system's reactive power demand, clearly revealing the peak, trough and change pattern of the reactive power.

Based on the data analysis, we also need to carefully assess the harmonic condition of the power system. In modern industrial power grids, non-linear loads such as frequency converters and rectifiers generate a large amount of harmonics. The presence of harmonics may cause overcurrent and overheating of capacitors, and in severe cases, it can lead to resonance. That is why in situations with severe harmonics, we recommend that customers use anti-harmonic intelligent capacitors or install tuned reactors instead of ordinary compensation equipment. Our engineering team, relying on this rigorous diagnostic process, customizes low-voltage reactive power compensation solutions for thousands of customers, ensuring that every KVAR of compensation capacity is used effectively.

The Inevitable Choice in the Intelligent Era: Dynamic Precise Compensation

In fact, for the majority of modern industrial and commercial enterprises, their loads are constantly changing. Simply discussing "static" fixed capacity configurations is no longer sufficient to solve all problems. This is precisely why Geyue Electric advocates and practices the "Dynamic Precise Compensation" concept.

The essence of "Dynamic Precise Compensation" lies in "compensation as needed and real-time response". It no longer relies on a fixed and extremely large capacity but instead uses advanced reactive power compensation controllers to monitor the power factor changes in the power system in real time. Like an experienced commander, the reactive power compensation controller intelligently switches on and off the appropriate number of capacitor banks. When large motors start up, the controller can quickly switch on the corresponding capacity of capacitors. When the load is reduced, the controller can promptly switch off some capacitors. The aim is to always keep the power factor stable within the target range (usually between 0.95 and 0.98).

This "Dynamic Precise Compensation" strategy perfectly combines the rationality of "precise calculation" with the flexibility of "dynamic response". It not only avoids the risk of over-compensation caused by excessive fixed capacity, but also solves the problem of insufficient fixed capacity during certain periods. What it brings is a more stable system voltage, purer power quality, and an economic return that continuously saves your electricity expenses throughout the entire equipment lifecycle.

The Solutions and Professional Commitment of Geyue Electric

At Geyue Electric, we deeply understand that an excellent low-voltage reactive power compensation solution begins with precise on-site diagnosis, is achieved through reliable equipment support, and ultimately leads to long-term value returns. We absolutely do not encourage customers to make any unnecessary or wasteful excessive investments.

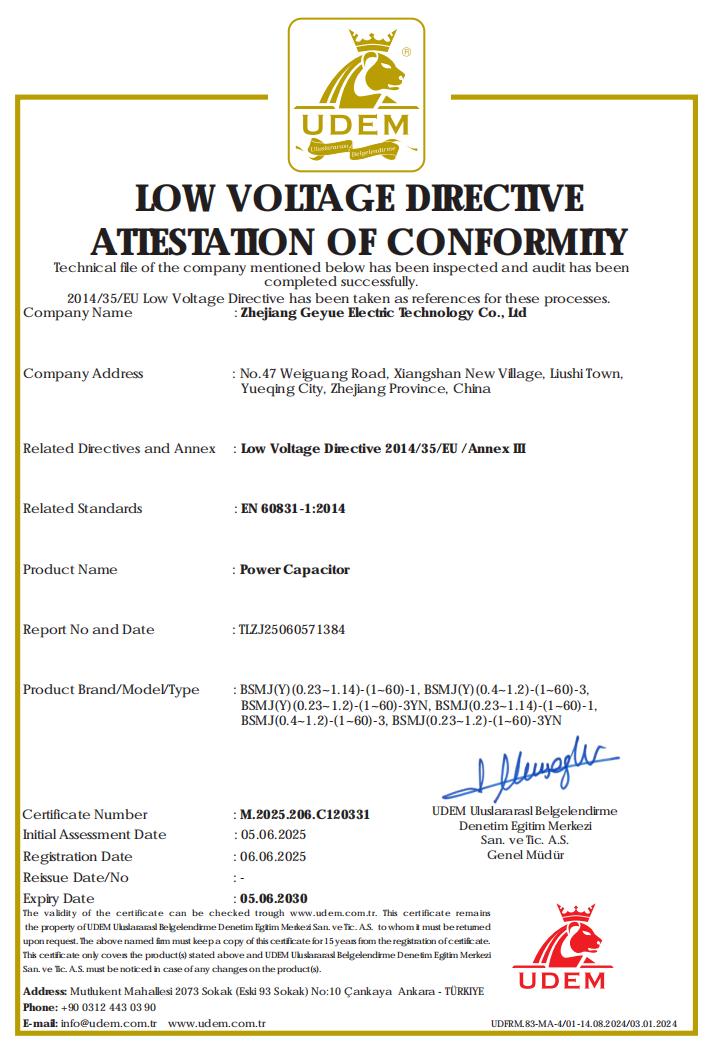

Our intelligent low-voltage reactive power compensation system is equipped with a power factor controller that employs advanced algorithms. The controller performs calculations accurately and responds promptly, enabling it to easily handle rapid changes in load. The anti-harmonic intelligent capacitor we provide uses a high-quality material, metallized polypropylene film, which features dry, oil-free operation and good self-healing properties. This ensures the equipment's high reliability and long lifespan in complex power grid environments. What's more, our company has an experienced professional team that is willing to get involved in the project at an early stage and offer free preliminary assessment of power quality and consultation on scheme design.

Geyue Electric firmly believes that a scientific, tailor-made and precise compensation plan is far more valuable than a simple and crude "large capacity" list. It not only provides a solid guarantee for the long-term stable operation of your power system, but also offers the strongest support for your enterprise's goal of cost reduction and efficiency improvement.

We sincerely invite you to choose Geyue Electric as your professional partner for power quality management. Let us work together with precise calculations and intelligent equipment to create a safer, more economical and more efficient green power grid for you. Please send your inquiry to info@gyele.com.cn.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.

- How Can We Effectively Educate the Market and Enable Customers to Recognize the Long-Term Value Brought by "High-Quality Compensation"?