Two Products of Geyue Electric Obtained EU CE Certification, Achieving a Key Breakthrough in Expanding the Global Market

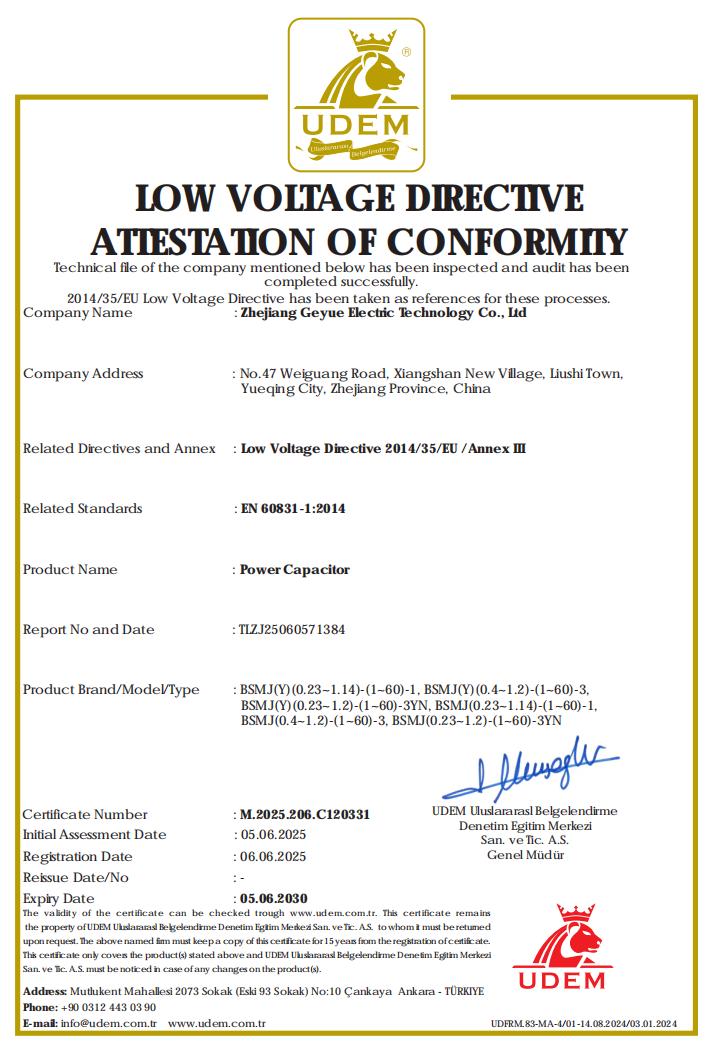

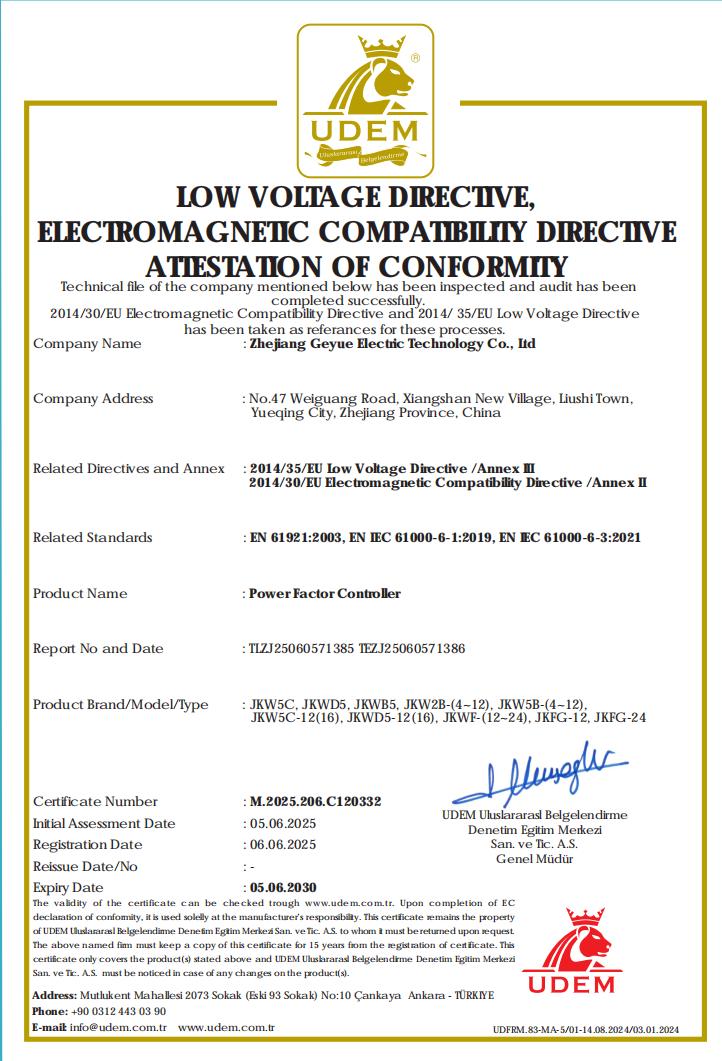

The BSMJ Self-healing Shunt Capacitor and JKW intelligent compensation Automatic Power Factor Controller independently developed by Geyue have passed the EU CE safety certification and obtained the mandatory access to the EU market. This certification includes dual tests of low voltage electrical safety (LVD) and electromagnetic compatibility (EMC), and the products can be directly sold and used in 30 countries including Germany and France.

BSMJ Self-healing Shunt Capacitor core technology verification

Continuous and stable operation in extreme environments

After being frozen for 48 hours in a low-temperature environment of -25 degrees Celsius, the BSMJ series self-healing shunt capacitor can directly carry the rated working current without preheating, and there is no shell cracking or dielectric leakage during the entire test. After running continuously for 1000 hours under an overvoltage condition of 150% of the rated voltage, the internal pressure protection device did not trigger the pressure relief action, and the capacitor dielectric did not show any breakdown failure.

Environmentally friendly materials double certification

The metallized film material of the BSMJ series self-healing capacitor has passed the EU RoHS 2.0 Restriction of Hazardous Substances Directive test, confirming that the content of six types of heavy metals such as lead, cadmium, and mercury is zero. The value of each ton of recycled materials after scrapping and dismantling has increased by US$30 compared with traditional products, and meets the extreme working conditions of direct start operation after freezing at -25℃ and 150% overvoltage without leakage for 1,000 hours.

JKW Automatic Power Factor Controller core technology verification

Accurate measurement in strong electromagnetic interference environment

The JKW Automatic Power Factor Controller can still maintain accurate measurement when facing high-frequency strong electromagnetic interference of 30V/m. Two 15KW inverters are used on site to run continuously close to the controller cabinet. The error of the reactive power value displayed in real time by the system is strictly controlled within ±1%. For example, when the actual reactive power is the standard value of 100 kvar, the measurement result is stable in the range of 99.2 to 100.8 kvar. This performance is achieved by the collaborative anti-interference mechanism of the three-stage filter circuit and the sampling signal digital isolation technology.

Communication security and environmental tolerance verification

The communication port of the JKW controller (including RS485 and Ethernet interface) can directly withstand 4000V AC voltage shock, and the measured peak voltage resistance reaches 4120V, which is twice the EU basic safety standard of 2000V. The communication chip and the main control circuit adopt a physical isolation design, with an isolation voltage of up to 5000 volts and an insulation resistance of more than 10GΩ, which is equivalent to blocking 99.99999% of the leakage current, ensuring that the hardware is not damaged under strong electric shock and the signal transmission is not distorted.

The core circuit board of the JKW Reactive Power Auto Compensation Controller uses a nano-level three-proof coating to effectively isolate water vapor, dust and corrosive media from erosion. After a 96-hour high-intensity salt spray test (simulating a 5% concentration seawater environment), the insulation resistance of the equipment is stably higher than 100 megohms, far exceeding the national standard requirement of 10 megohms; the metal contacts have no oxidation and rust after a 50x microscope inspection, verifying its ten-year long-term protection capability in high-corrosion scenarios such as coastal and chemical industries.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.