Why Are Intelligent Capacitors Becoming the New Standard in Modern Industrial Plants?

In the era of steady advancement of Industry 4.0, major breakthroughs in intelligent technologies such as robots, the Internet of Things, and artificial intelligence, along with the positive guidance of sustainable development incentive policies from governments around the world, jointly drive modern factories to gradually phase out traditional ones. Intelligent, flexible and green modern factories will become the inevitable form of future factories and the inevitable product of industrial intelligence. To address key issues such as greater load fluctuations and higher power quality requirements in modern industrial scenarios, intelligent capacitors have replaced traditional capacitors and become the standard choice for modern factories. In the following article, we will explore the important reasons behind intelligent capacitors becoming the new standard for modern factories.

The Upgrade of Technical Standards Makes It Inevitable That Intelligent Capacitors Will Fully Take over Industrial Scenarios.

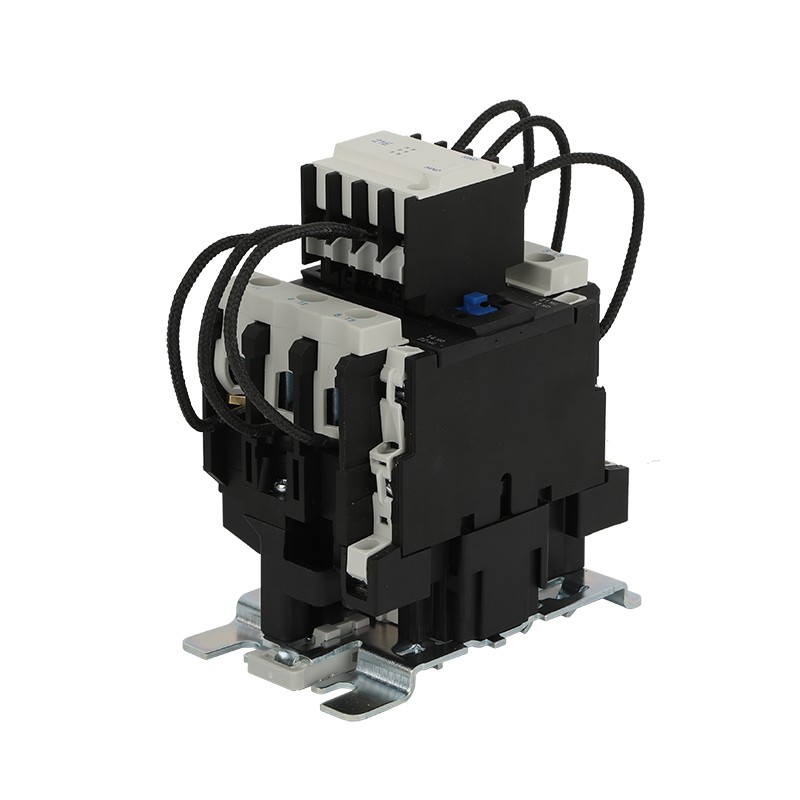

Intelligent capacitors are showing a trend of gradually replacing and eventually completely replacing traditional capacitors in terms of compensation methods, functional integration, communication and intelligence. The response speed of traditional fixed-group capacitor banks is slow, with a response time greater than 100ms, and the power factor fluctuates greatly, fluctuating within ±0.2. In contrast, the compensation method of intelligent capacitors has been upgraded, avoiding the situations of excessive compensation or insufficient compensation that are prone to occur in traditional capacitors. By monitoring load changes in real time, intelligent capacitors can respond quickly (the response time is even compressed to 1/5 of that of traditional capacitors), automatically and dynamically adjust the compensation capacity, increase and stabilize the corresponding power factor above 0.95, that is, control the reactive power loss of the power grid within 5%, meeting the stable operation requirements of the power system in the industrial field. The compensation scheme for traditional capacitors requires additional configuration of PFC Components, such as anti-harmonic reactors, contactors for switching capacitors, and power meters for monitoring circuit data, etc. In contrast, the intelligent solution of intelligent capacitors is a perfect interpretation of functional integration: The compensation solution of intelligent capacitors does not require other PFC Components, because a smart capacitor with an integrated reactor has already integrated functions such as reactive power compensation, harmonic suppression, and condition monitoring. In the typical structure of traditional capacitors, there is no intelligent control unit or data interface, and they do not have remote communication capabilities such as remote monitoring, parameter adjustment, and fault early warning. In contrast, the most notable functions of intelligent capacitors are communication and intelligence. Intelligent capacitors support protocols such as Modbus and can be connected to the factory's energy management system to achieve remote monitoring, parameter adjustment, fault early warning and other remote communication capabilities.

The Figher ROI of Intelligent Capacitors Has Become A Consensus among Industrial Electricity Users.

Reducing costs and increasing profits are the specific manifestations of intelligent capacitors proving to industrial electricity users that choosing intelligent capacitors will generate a higher return on investment than choosing traditional capacitors. From the perspective of direct benefits, intelligent capacitors can play a role in saving electricity bills by precisely compensating and reducing reactive power fines. Meanwhile, intelligent capacitors can extend their lifespan to tens of thousands of hours through thyristor switching, and the annual maintenance cost can drop by more than 50%. From the perspective of indirect benefits, the harmonic suppression protection devices such as frequency converters integrated in the intelligent capacitor can prevent production line interruptions in the factory, reduce workshop downtime losses, and at the same time, the intelligent capacitor can ensure a stable voltage system with a voltage fluctuation range of less than ±2%, thereby increasing the service life of other equipment in the system, such as motors and transformers, by 10% to 20%.

New Standards in the Global Power Industry are Promoting the Popularization of Intelligent Capacitors among Industrial Enterprises.

Under the impetus of new standards in the domestic and international power industry and the incentives of relevant policies from various international organizations, the intelligence of capacitors is penetrating the industrial sector at an unprecedented speed. The IEC63180 standard for smart grid equipment mandates that communication interfaces support protocols such as IEC 61850 or Modbus, compelling manufacturers to phase out traditional capacitors without communication functions. The GB/T 22582-2023 Chinese energy efficiency standard directly classifies the energy efficiency of reactive power compensation devices into three levels, with the highest being Level 1 energy efficiency (power factor ≥0.99, THD<3%). Starting from 2025, products below level 3 will be completely eliminated from the market. Under China's "dual carbon" goals, many regions have begun to offer 30% subsidies to industrial enterprises undergoing intelligent energy-saving renovations (for instance, Jiangsu Province provides rewards to industrial enterprises with a power factor >0.95). The EU ERP directive strictly requires that the power factor of industrial equipment must not be lower than 0.9, which forces the intelligent upgrade of reactive power compensation systems in industrial enterprises across Europe.

The core pain points of traditional capacitors lie in static compensation, passive response and isolated operation, which are seriously disconnected from the dynamic, predictive and interconnected demands required for industrial intelligence. Intelligent capacitors have solved these pain points one by one by integrating sensing, communication, adaptive control and other technologies, and have provided industrial enterprises with a higher return on investment. They comply with the new standards for power quality management in industrial enterprises implemented internationally and by various countries, and have become an inevitable choice for the upgrade of low-voltage reactive power compensation systems in industrial plants. Geyue Electric are truly dedicated in developing more and more innovative intelligent capacitors to respond market demands and industry trends. Explore our full range of products on our website at https://www.geyuecapacitor.com/. For any inquiries, please reach out to us at info@gyele.com.cn.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?