Is the Noise Control of Low-Voltage Reactive Power Compensation Equipment (Especially for Dynamic Compensation Devices) a Neglected Competitive Advantage?

In the traditional selection and evaluation of low-voltage reactive power compensation equipment, technical parameters, price costs, and operational reliability constitute the three main pillars of the purchasing decision. However, in today's era where green building standards are continuously evolving and the concept of humanistic care is deeply rooted, the technical detail of noise control for low-voltage reactive power compensation equipment is emerging from the background and becoming one of the most important evaluation criteria beyond the three main pillars. Geyue Electric believes that, especially in the field of dynamic compensation devices that require frequent switching, noise control is not only a technical indicator but also a core competitive point that has been underestimated for a long time and is about to reveal its decisive value.

The Transformation of Silent Operation from a Marginal Demand to a Core Value

In the past, the operational noise of low-voltage reactive power compensation equipment was often regarded as a secondary issue, as long as it did not exceed the broad standards of industrial environments. This outdated perception is rapidly changing as the application scenarios of low-voltage reactive power compensation equipment become more diverse. When the compensation equipment moves from standalone distribution rooms to spaces closely connected to human environments such as office buildings, hospitals, schools, and data centers, the continuous buzzing or sharp switching noises are no longer just background noise; they directly affect the comfort of the working environment, the recovery and recuperation of patients, the focused learning of students, and the acoustic cleanliness of the environment where precision instruments are located. At this point, silent operation has transformed from an optional choice to a fundamental requirement for an inductive reactive power compensation system. Because noise control directly reflects the in-depth understanding and humanistic concern of low-voltage reactive power compensation equipment manufacturers for the end-user experience, this kind of concern itself constitutes an important part of the brand value.

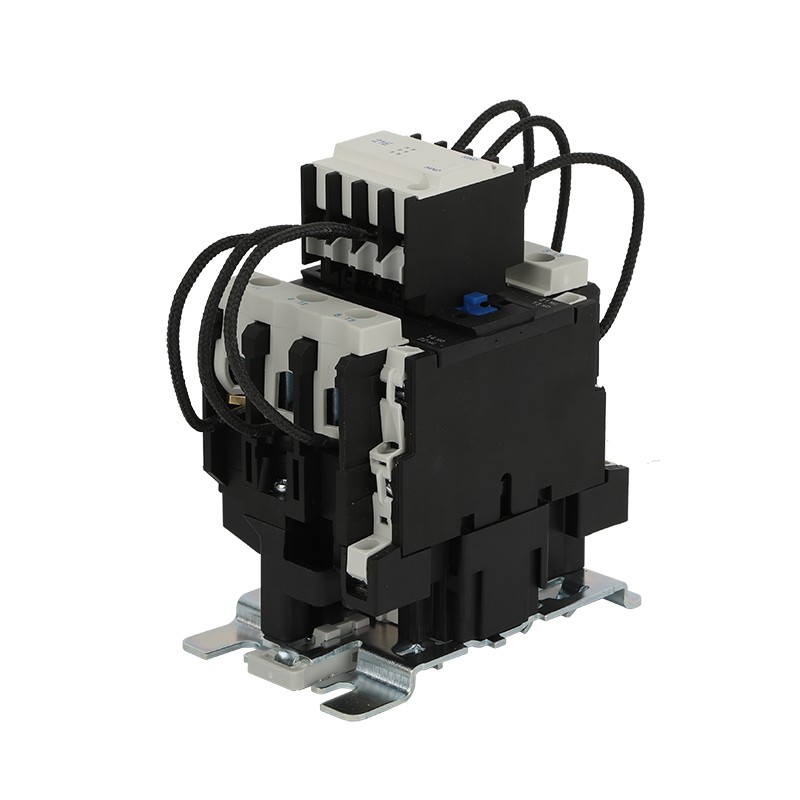

The Unique Challenges and Root Causes of Noise from Dynamic Compensation Devices

Compared to traditional contactor switching devices, dynamic compensation devices face more severe challenges in noise control due to their distinct working principles. Traditional contactors produce clear electromagnetic attraction sounds and contact impact sounds when they operate, but their operating frequency is limited and the sounds are intermittent. In contrast, the noise source of the dynamic compensation device based on thyristors is more complex and continuous. During high-frequency switching, the cooling fan of the thyristor itself will generate continuous airflow sounds. When current passes through semiconductor components and the busbar, it may cause specific frequency electromagnetic hums. What's more, the magnetic expansion effect produced by the reactor inside the device under non-sinusoidal current will emit a strong penetrating and irritating continuous high-frequency noise. Although the volume of this noise may not be extremely high, its specific frequency characteristics make it easier to be perceived in the environment and more difficult to be isolated.

The Technical Background and Brand Metaphor behind the Silent Design

Raising noise control to a strategic level is far more than simply covering the equipment with sound insulation materials. It is a profound test of an enterprise's comprehensive technical capabilities. Excellent noise reduction performance is the inevitable outcome of exquisite design and high-quality material selection. It means that the reactor uses low magneto strictive materials and an optimized core structure to suppress vibrations at the source. The fan selects a silent model with high precision dynamic balance and is supplemented by scientific air duct design. The mechanical structure adopts a strategy combining damping vibration and rigid reinforcement to block resonance transmission. Even the control algorithm has been optimized to avoid the working points that are prone to cause resonance. Therefore, a manufacturer that can effectively control the noise of the dynamic compensation device below the industry average level, its products convey a deeper message beyond the parameter table, which is an unspoken declaration about excellent craftsmanship, rigorous quality control, and forward-looking design concepts. Customers have reason to believe that a supplier who is meticulous in such details is bound to be more trustworthy in terms of the quality of core components and long-term reliability.

The Manifestation of Silent Value throughout the Entire Project Life Cycle

The competitive advantages of silent equipment are present throughout the entire lifecycle of the project and ultimately translate into tangible economic value and brand reputation. During the bidding stage, clear and leading noise indicators can help the project gain bonus points in the green building certification process and become a prominent highlight in the technical assessment. During the installation and commissioning stage, low-noise equipment reduces the need for additional engineering tasks such as installing sound insulation covers or modifying ventilation systems to handle noise, thereby lowering the overall cost. Over a ten-year operation and maintenance period, silent operation means lower mechanical and electrical stress, indicating a longer equipment lifespan and fewer maintenance requirements. It directly improves the environmental quality of the space where the equipment is located, avoiding subsequent renovation disputes caused by employee complaints or customer dissatisfaction, and bringing about productivity and satisfaction improvements of immeasurable value.

Geyue Electric firmly believes that the pursuit of noise control for low-voltage reactive power compensation equipment, especially for dynamic compensation devices, is moving from a neglected corner to the center of the world stage in the field of low-voltage reactive power compensation. Noise control is no longer an optional additional function in the low-voltage reactive power compensation domain; instead, it has become a key dimension for evaluating whether a set of low-voltage reactive power compensation equipment truly possesses modernity, humanistic care, and outstanding quality. In the future market competition, power enterprises that can first integrate silent technology into their core competitiveness will undoubtedly win the favor and trust of more discerning customers on the new track of pursuing high quality and sustainable development. And we at Geyue Electric are one of those who are tirelessly striving for this. If you are interested in silent reactive power compensation systems, please feel free to write to info@gyele.com.cn and communicate with our technical team.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?