Dielectric Revolution: How Do Microcrystalline Wax Power Capacitors Defeat Both Oil-Immersed And Dry-Type Capacitors?

In the field of industrial power compensation, traditional oil-immersed capacitors have the risk of solidification at low temperatures and explosion at high temperatures, and dry epoxy capacitors will age faster at high temperatures. Microcrystalline wax power capacitors rely on paraffin-nano-montmorillonite composite media to achieve stable operation in the full temperature range from -45°C antifreeze to 200°C heat resistance, and can withstand 150kJ arc energy without bursting. The dielectric strength is increased to 65kV/mm. This article will verify the technical advantages of microcrystalline wax power capacitors compared to oil-immersed and dry types by introducing dielectric material properties, extreme temperature adaptability, explosion-proof safety performance, anti-harmonic capability, cost analysis, and environmental protection.

Dielectric material properties

Microcrystalline wax power capacitors are capacitors made of composite paraffin-based dielectric materials. The material is a composite modification of high-purity paraffin and nano-montmorillonite. Its dielectric strength is as high as 65kV/mm, which is 30% higher than the 55kV/mm of traditional oil-immersed capacitors and 8% higher than the 60kV/mm of dry epoxy capacitors. The dielectric loss tangent value is stable within 0.15%, which is lower than the 0.5% of oil-immersed capacitors and 0.3% of dry capacitors.

Extreme temperature adaptability

Microcrystalline wax power capacitors can maintain normal operation in an environment of minus 45°C, and environmental tests show that the capacity deviation is only 2.1%. They can also work normally in an environment with a temperature of up to 200°C. In environmental tests, when the internal temperature of the capacitor reaches 155°C and the capacity changes for 2000 hours of continuous operation, it does not exceed 5%. Actual operating data shows that when operating in an environment of minus 42 degrees Celsius at the Mohe substation in Heilongjiang, the capacity deviation is only 2.1%. There is no swelling when operating at a high temperature of 98 degrees Celsius inside the compensation cabinet of the Guangdong foundry, and the equipment can maintain stable operation. However, the oil-immersed type will solidify and fail below -25°C, and the dry type is prone to cracking at -35°C.

Explosion-proof safety performance

The explosion-proof safety performance has been verified by international standards. Through the 10kA/20ms arc test of the IEC 60871 standard, the microcrystalline wax power capacitor can absorb 150kJ of arc energy without bursting. In the event of a fault, the material will melt and fill the breakdown point within 5ms, forming a permanent insulating isolation layer. The long-term monitoring data of the Shanghai Metro compensation cabinet shows that the capacity attenuation rate of the capacitor after self-healing is less than 0.3%, which is better than the attenuation of more than 5% of the oil-immersed capacitor.

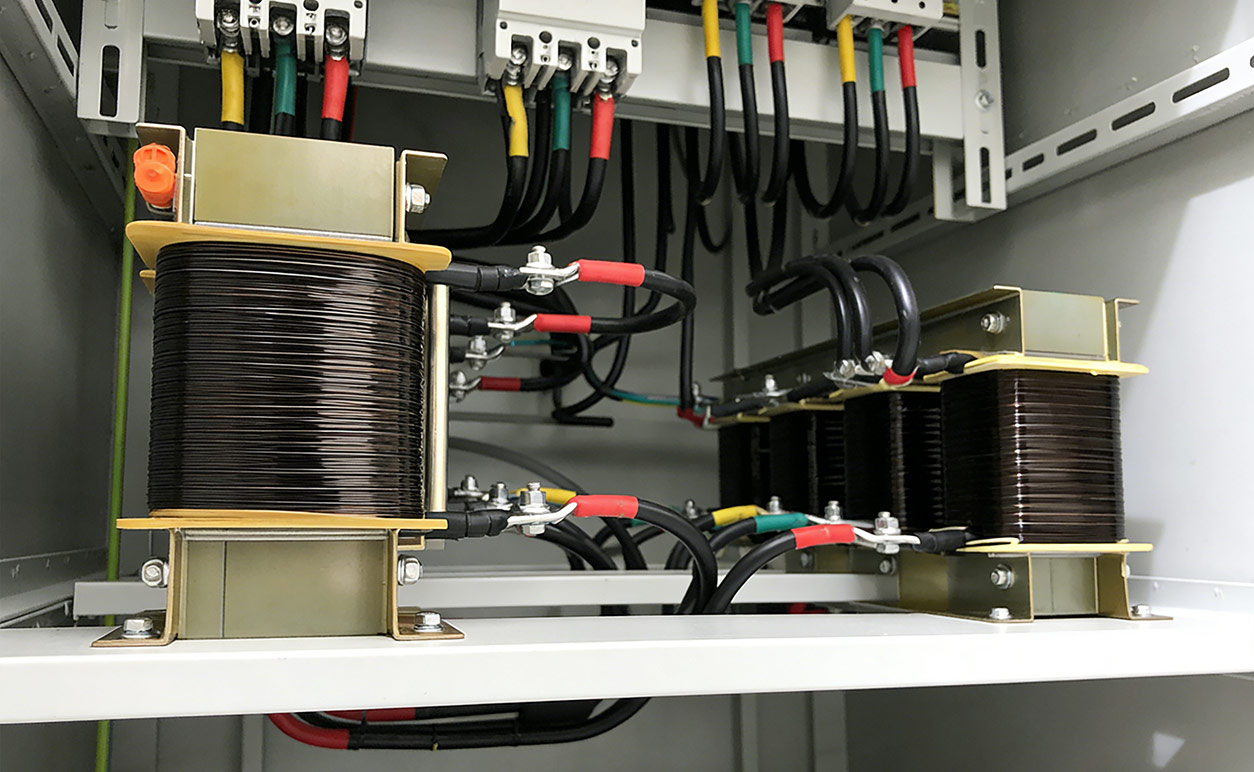

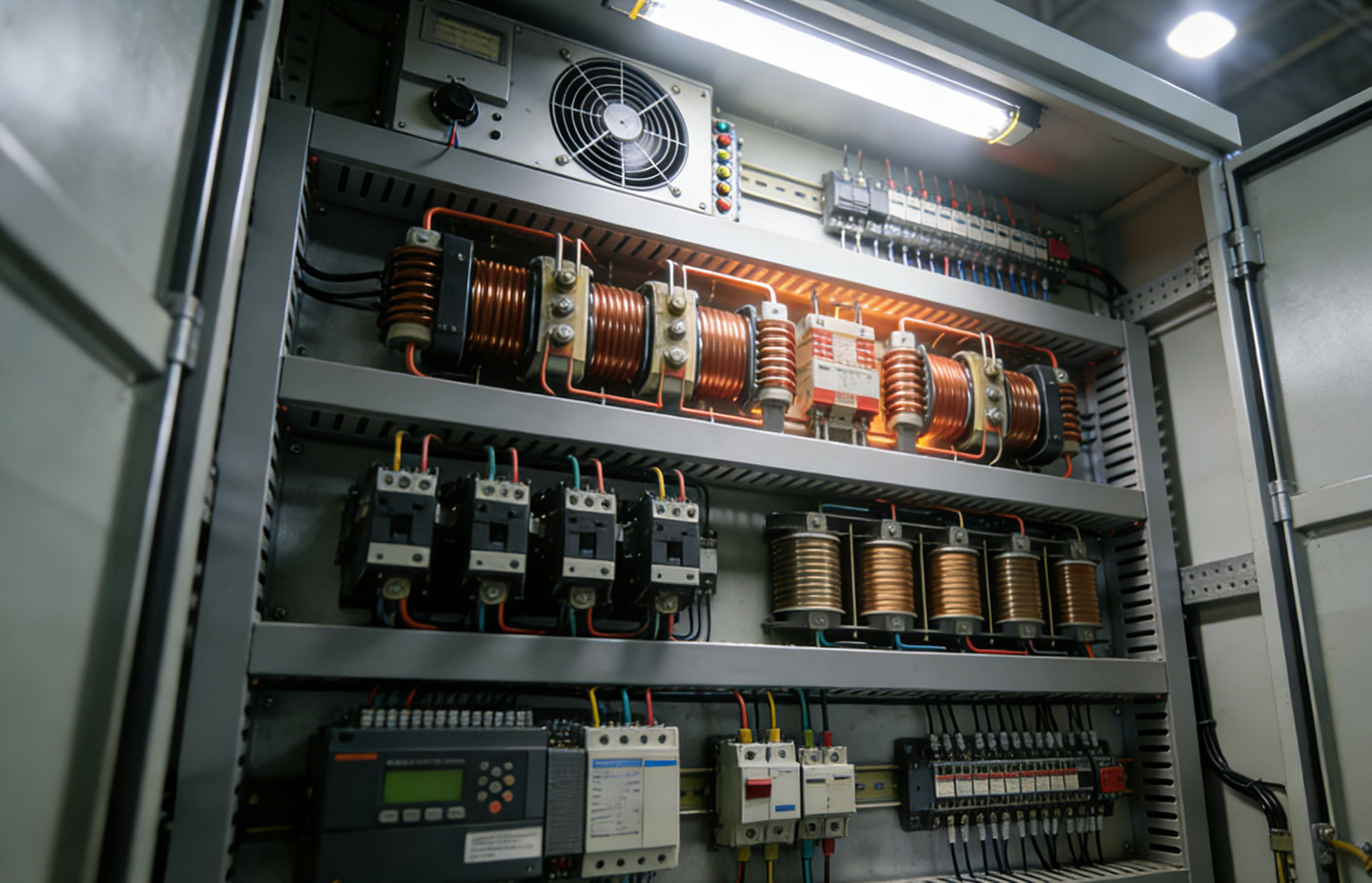

Anti-harmonic capability

The electrical performance parameters have long-term stability. In an industrial harmonic pollution environment, that is, under the condition of current distortion rate THDi=25%, the operating temperature rise of the microcrystalline wax power capacitor is controlled within the range of 40K. This is thanks to the design of 3 micron thickened zinc-aluminum composite electrode, which can withstand 2.5 times the rated current. The application of the rolling mill production line transformation project of a steel plant in Beijing shows that after three years of continuous operation of the equipment, the capacity attenuation rate is only 1.2%.

Zero maintenance cost

The maintenance cost structure has changed fundamentally. The microcrystalline wax power capacitor uses a fully sealed laser welding process, and the shell protection level reaches IP68. After operating in the high salt spray environment of the South China Sea drilling platform (the salt spray concentration reaches GB/T 10125 standard level 6) for five years, there was no terminal corrosion or insulation degradation. The aging rate test value of the equipment body is 0.5% per year, and the service life is as long as 15 years, while the oil-immersed capacitor has a life of only 6-8 years.

Environmentally friendly recycling

The scrapping of microcrystalline wax power capacitors meets the requirements of the circular economy. After the capacitors are discarded, they can be disassembled and recycled at a low temperature of 70 degrees Celsius. The purity of the recycled microcrystalline wax can reach 99.2%, and the performance can still meet the standards after being recycled for more than 5 times. The recycling rate of metal electrode materials exceeds 96%. The regeneration value of each ton of scrapped capacitors can reach US$4,000, which meets the requirements of the EU RoHS 2.0 environmental protection directive and China's environmental protection certification.

Geyue Electric uses microcrystalline wax power capacitor technology to completely solve the problems faced by industrial compensation equipment under extreme working conditions. The capacitor can maintain stable operation in environments ranging from -45℃ to 200℃, and has passed the rigorous verification of the Daqing Oilfield's 42℃ heating-free operation and the Guangdong Foundry's 98℃ high temperature. Its innovative 150kJ arc tolerance and 5 millisecond melting self-healing mechanism have eliminated the risks of oil-immersed burst and dry capacitor breakdown in practical applications. Baosteel Group's ten consecutive years of zero-failure operation records have verified the 15-year maintenance-free life cycle design, reducing the full-cycle cost of the equipment to one-ninth of the traditional solution. At present, this technology has achieved a 96% material recovery rate and five-cycle regeneration in key projects such as the PetroChina drilling platform and the Shanghai Metro, providing various industries with power compensation solutions that take into account safety, life and environmental protection. Welcome to visit Geyue Electric's official website https://www.geyuecapacitor.com/ for customized services.

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?