Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

In the field of low-voltage reactive power compensation and harmonic control, if you observe carefully, you will surely notice a common phenomenon: whether in new projects or renovation works, the vast majority of series reactors have adopted the dry-type iron-core structure. As an engineer with extensive experience in the industry at Geyue Electric, I am often asked by customers: Why does the dry-type iron-core structure becomes the mainstream choice in the market? Compared with the air-core type, oil-immersed iron-core type, and other structures, what exactly makes the dry-type iron-core structure superior? Today, I will reveal the technical logic and business considerations behind the dry-type iron-core structure of series reactors.

Principal Benefits: The Perfect Balance among Performance, Cost, and Reliability

The success of dry-type iron-core series reactors lies in their ability to strike a nearly perfect balance among key performance, manufacturing cost, and long-term reliability. If we compare the air-core series reactors to "unchanging linear guardians", and the oil-immersed iron-core series reactors to "large-capacity heavily-armed warriors", then the dry-type iron-core series reactors are the "flexible and efficient tactical experts".

The principal benefits of dry-type iron-core series reactors are their small size and high efficiency. Thanks to the silicon steel sheet core with high magnetic permeability, the dry-type iron-core series reactors require far fewer coil turns than the air-core series reactors under the same inductance, resulting in smaller volume, lighter weight and less copper material consumption. This characteristic directly meets the urgent demand of modern compact distribution cabinets for equipment miniaturization, allowing system integrators and end users to install more and more powerful compensation and filtering circuits in limited space.

Technical Essence: The Art of Gap Design and Inductance Stability

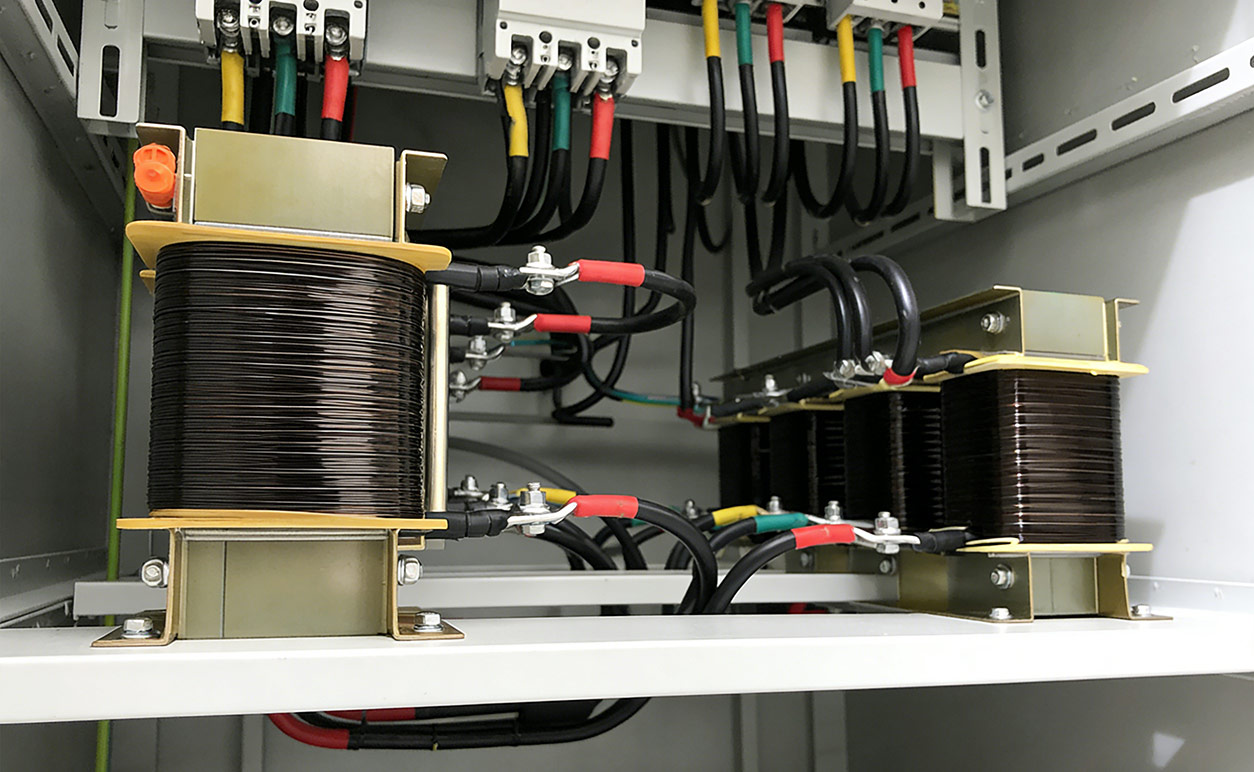

The true technical essence of the dry-type iron-core series reactors rests with their unique segmented air-gap iron core design. Pure iron cores are prone to magnetic saturation under large alternating current, causing a sharp drop in inductance and failure. However, professional manufacturers like we, Geyue Electric, have ingeniously solved this problem by inserting multiple uniform air gaps separated by materials such as epoxy laminated boards into the iron core.

These air gaps significantly increase the magnetic resistance of the magnetic circuit, enabling the dry-type iron-core series reactors to maintain a high level of inductance stability from no-load to full-load, even when subjected to certain levels of overcurrent and harmonics. The stable inductance is the foundation for precisely achieving target reactance rates of 7% or 14%, and ensuring that the filtering branch accurately presents high impedance at the preset harmonic frequencies (such as 5th harmonic, 7th harmonic). In simpler terms, the design and curing process of the air gaps directly determine the performance quality and service life of the dry-type iron-core series reactors.

Reliability and Safety: The Reassuring Guarantee Brought by Dry Insulation

The term "dry-type" represents another crucial reliability option: the reassuring guarantee brought by dry insulation. Compared with traditional oil-immersed iron-core series reactors, the dry-type structure does not require insulating oil, completely eliminating the risks of oil leakage and fire, and also eliminating the troubles and costs associated with subsequent maintenance and replacement of insulating media. Modern dry-type iron-core series reactors adopt insulation systems with high heat resistance levels such as F-class or H-class, and the coils undergo vacuum pressure impregnation treatment to be firmly combined with the iron cores. Modern dry-type iron-core series reactors not only have excellent heat dissipation performance, but also can withstand the severe thermal tests brought by high temperatures and harmonics, achieving maintenance-free and long-lasting operation.

Geyue Electric’s Practice: The Ultimate Pursuit in Mainstream Tracks

In the opinion of Geyue Electric, our choice of the dry-type iron-core structure, which is the mainstream type of series reactors on the market, as the structure of our best-selling series reactors, does not mean that our company blindly follows market trends. Instead, it is based on our company's focused and ultimate pursuit after a deep understanding of market demands.

In the production of the CKSG series series reactors by Geyue Electric, starting from the selection of high-quality, low-loss silicon steel sheets, to the precise and uniform winding of the flat copper wire coils by CNC technology, and then to the precise calculation and solidification process of the air gap, every step embodies the strict demands of our entire R&D team for "stability" and "reliability". We use advanced VPI vacuum pressure impregnation equipment and H-class insulating paint to ensure that the coils, cores and air gaps form a solid whole after high-temperature solidification. This process not only effectively reduces the electromagnetic noise of our series reactors during operation, but also raises the heat resistance level and mechanical strength of our series reactors to the forefront of the industry.

It is precisely this in-depth study of mainstream technologies and the continuous refinement of manufacturing processes that have enabled the CKSG series reactors of Geyue Electric to achieve outstanding performance in key indicators such as volume, weight, temperature rise and noise. Our series reactors not only meet all the expectations of the market for the mainstream structure, but also safeguard the efficient and quiet operation of your reactive power compensation system and filtering system for ten years through their superior stability and durability beyond the standards of similar products.

Therefore, when you select series reactors for your power system, choosing the mainstream dry-type iron-core structure is a well-researched and wise decision; while choosing a brand like Geyue Electric that focuses on the dry-type iron-core structure and perfects it to the utmost, will add the most reliable value guarantee to this decision. Please send your filtering protection requirements for your low-voltage reactive power compensation system to our email address info@gyele.com.cn. We at Geyue Electric will strive to turn every seemingly standard series reactor into a solid barrier to protect the safe operation of your system.

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?