What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

Introduction: Let's Start with the Basic Concepts

In low-voltage power distribution systems, reactive power compensation technology plays a crucial role in improving power quality and reducing line losses. As a manufacturer of low-voltage reactive power compensation equipment in China, Geyue Electric is well aware of the confusion and selection dilemmas faced by users in practical applications: What exactly is the boundary between static compensation and dynamic compensation? Which of the two should be chosen? In fact, these two technologies of static compensation and dynamic compensation are not simply opposed to each other; rather, they are each advantageous solutions in different application scenarios. Correctly understanding the essential differences between static compensation and dynamic compensation can help users make more accurate choices for reactive power compensation, achieving the best balance between economic benefits and technical performance.

Technical Principle: The fundamental Difference in Response Mechanisms and Respond Speeds

The core boundary between static compensation and dynamic compensation lies in their response mechanisms and speeds to load variations. Static compensation typically refers to the traditional reactive power compensation method using CJ19 series capacitor switching contactors to switch on and off capacitors. The overall response time of static compensation usually ranges from several hundred milliseconds to several seconds. This compensation method monitors the reactive power of the power system and switches on and off fixed-capacity capacitor banks in segments, and is suitable for scenarios where the load is relatively stable and changes infrequently.

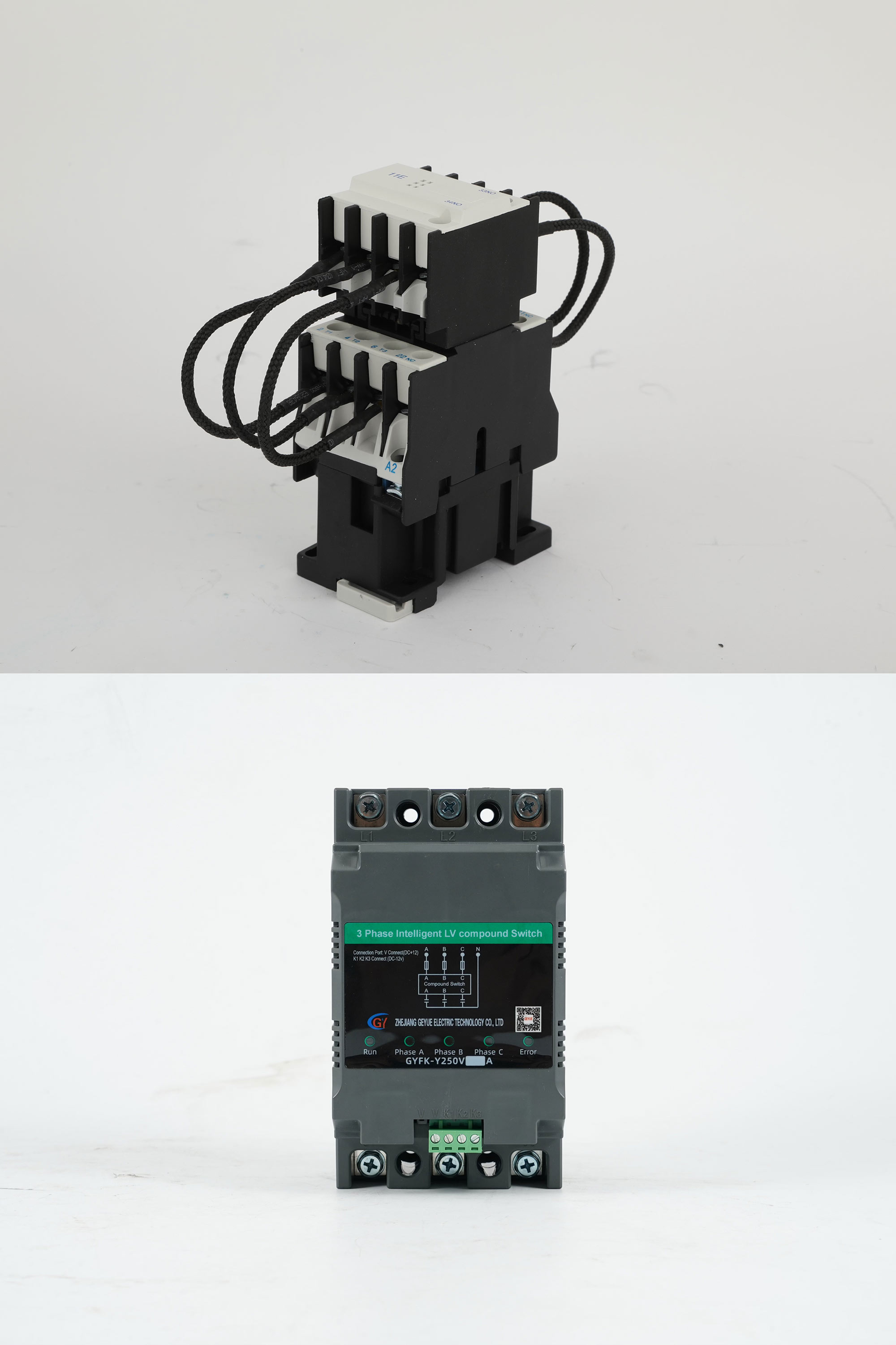

Dynamic compensation employs semiconductor devices such as GYKCS1A series thyristors or GYFK series compound switches with IGBT modules implanted for contactless switching. The overall response time is only in the millisecond or even microsecond range. Dynamic compensation can accurately track the reactive power changes of the load in real time, achieving smooth and continuous reactive power compensation. It is particularly suitable for industrial scenarios with highly fluctuating loads such as arc furnaces, rolling mills, and welding equipment. The differences in response mechanisms and response speeds between static compensation and dynamic compensation determine the fundamental differences in their applicable fields.

Application Scenarios: The Dividing Line Between Stability and Fluctuation

From the perspective of application scenarios, the boundary between static compensation and dynamic compensation is clearly defined in terms of load characteristics. Static compensation is mainly applied in scenarios such as residential buildings, commercial complexes, and ordinary factory workshops where the load changes are gentle and the harmonic content is low. In these scenarios, the requirement for compensation speed is not high. Compared to compensation speed, these scenarios place greater emphasis on cost-effectiveness and operational reliability in reactive power compensation.

Dynamic compensation is specifically designed for special industrial environments where the load changes rapidly and has strong impact, such as the welding production lines in automobile manufacturing plants, the lifting operations of port cranes, and the precision equipment in semiconductor manufacturing enterprises. In these scenarios, the reactive power demand fluctuates rapidly, and traditional static compensation cannot keep up with the rapid changes in the load, resulting in significant fluctuations in power factor and even overcompensation or undercompensation problems. Dynamic compensation compensates for reactive power at a speed that is at least 10 times faster than static compensation, which can stabilize the power factor within the set range and ensure the power quality of the power grid.

Performance Indicators: Multi-Dimensional Comparison of Measurement Standards

Apart from response speed, there are also significant boundaries in multiple performance indicators between static compensation and dynamic compensation. The static compensation switching device (mainly the CJ19 series contactors), which is a type of complete reactive power compensation switching equipment using a mechanical switch as a switching element, has a relatively simple structure, lower initial investment, and is convenient to maintain. However, this static compensation switching device will generate inrush current and operational overvoltage when switching inductive capacitors, which has a certain negative impact on the lifespan of the capacitors, and is not suitable for scenarios that require frequent switching.

Dynamic compensation can achieve zero-crossing switching, without inrush current impact, significantly extending the service life of capacitors, and at the same time avoiding voltage flicker problems during the switching process. However, the technical complexity of dynamic compensation is high, and the initial investment is large. It also has higher requirements for heat dissipation and protection. In addition, dynamic compensation usually integrates harmonic filtering functions, which can handle more complex power quality issues, while traditional static compensation is prone to resonance risks in harmonic environments.

Consideration and Selection: The Art of Balancing Technology and Economy

In actual selection, the boundary between static and dynamic compensation is not so absolute. Instead, it requires comprehensive consideration of multiple factors for evaluation and decision-making. As a user of the low-voltage reactive power compensation system, the first and most important thing is that you should correctly analyze the load characteristics of your power system: if the load variation cycle is above several tens of seconds, static compensation is already sufficient to meet the system's reactive power compensation requirements; if the load fluctuates sharply within seconds or even shorter periods, then static compensation should be excluded and dynamic compensation must be implemented.

Secondly, users should carefully consider the overall investment budget and long-term benefits of the low-voltage reactive power compensation system. Although the initial cost of dynamic compensation is higher than that of static compensation, for inductive loads, dynamic compensation can more effectively avoid power factor assessment penalties, reduce line losses, increase equipment utilization, and the investment recovery period is often shorter than expected. In addition to balancing the technical and economic aspects of the reactive power compensation system as mentioned above, finally, users also need to take into account practical factors such as on-site installation conditions and operation and maintenance capabilities, so as to select the most suitable low-voltage reactive power compensation solution for your usage scenario.

Geyue Electric: Your Best Reactive Power Compensation Expert

As a manufacturer with a long history in the global reactive power compensation field, Geyue Electric has a deep understanding of the differentiated demands of customers from various industries for reactive power compensation. We hereby promise: Not only do we provide high-performance dynamic compensation devices, but we also produce cost-effective static compensation products, and are committed to finding the optimal combination of technology and economy for our customers.

The technical team of Geyue Electric can provide customized reactive power compensation solutions based on your load characteristics, grid conditions and development plans. Our dynamic compensation devices, GYKCS1A series thyristors or GYFK series compound switches, employ advanced predictive algorithms and rapid response technology to ensure stable operation in the most demanding industrial environments; while the static compensation devices, CJ19 series contactors, showcase excellent cost-effectiveness through optimized design and strict quality control in conventional applications. No matter which side of the requirements your need lies on, Geyue Electric can offer you professional assessment, precise selection and full-cycle services, helping you achieve the dual goals of improving power quality and optimizing energy costs. Drop your inquiry to our email box info@gyele.com.cn, let your best reactive power compensation expert, Geyue Electric, safeguard your power system with professional technology and dedicated services.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?