How Should the Selection of Switching Devices (Contactors, Thyristors, and Compound Switches) Be Optimized Based on Load Characteristics?

In the low-voltage reactive power compensation system, the switching device serves as the core component, and its performance directly affects the stability, response speed and lifespan of the compensation equipment. Contactors, thyristors and compound switches are common switching methods, each with its own applicable scenarios. As a manufacturer of low-voltage reactive power compensation equipment, Geyue Electric fully understands that the selection of the switch needs to be closely combined with the load characteristics to achieve the optimal operation of the system. The load characteristics include factors such as load type, variation frequency, current shock and harmonic content, which determine the switching speed, durability and anti-interference ability of the switch. Therefore, scientifically selecting switches can not only significantly improve the power quality of the electrical system, but also help users achieve efficient energy management by reducing energy consumption and maintenance costs.

Classification and Influence of Load Characteristics

Understanding the load characteristics is the prerequisite for selecting the switching device, as the load characteristics determine the electrical stress and environmental conditions that the switching device needs to withstand. In industrial applications, loads are typically mainly classified into resistive loads, inductive loads, and capacitive loads, etc. Resistive loads such as lighting and heating equipment have currents and voltages in the same phase, which may result in a relatively small inrush current during switch switching, but the requirement for the response speed of the switch is not high. Inductive loads such as motors and transformers are prone to generating high-amplitude surge currents and voltage spikes during switch switching, which requires the switching device to have strong anti-shock capabilities and rapid arc extinguishing functions. Capacitive loads are commonly found in compensation capacitors themselves. The switching process of compensation capacitors may cause instantaneous current surges, especially when frequently switched, which is likely to cause wear or overheating of the contact points of the switching device.

In addition, the frequency of load changes and the content of harmonics are also crucial factors in selecting a switch. For rapidly changing loads such as welding machines and frequency conversion equipment, a switching device with high-frequency switching capability is required to avoid voltage fluctuations caused by response delays. In a high-harmonic environment, such as a variable frequency drive system, it may cause electrical resonance or overheating problems, demanding a design that can resist harmonic interference. Geyue Electric has found in practice that ignoring the characteristics of the load often leads to premature failure of the switch or poor compensation effect. Therefore, in-depth analysis of the load type and operating mode is the first step in optimizing the selection of the switch.

The Applicable Scenarios and Limitations of Contactors

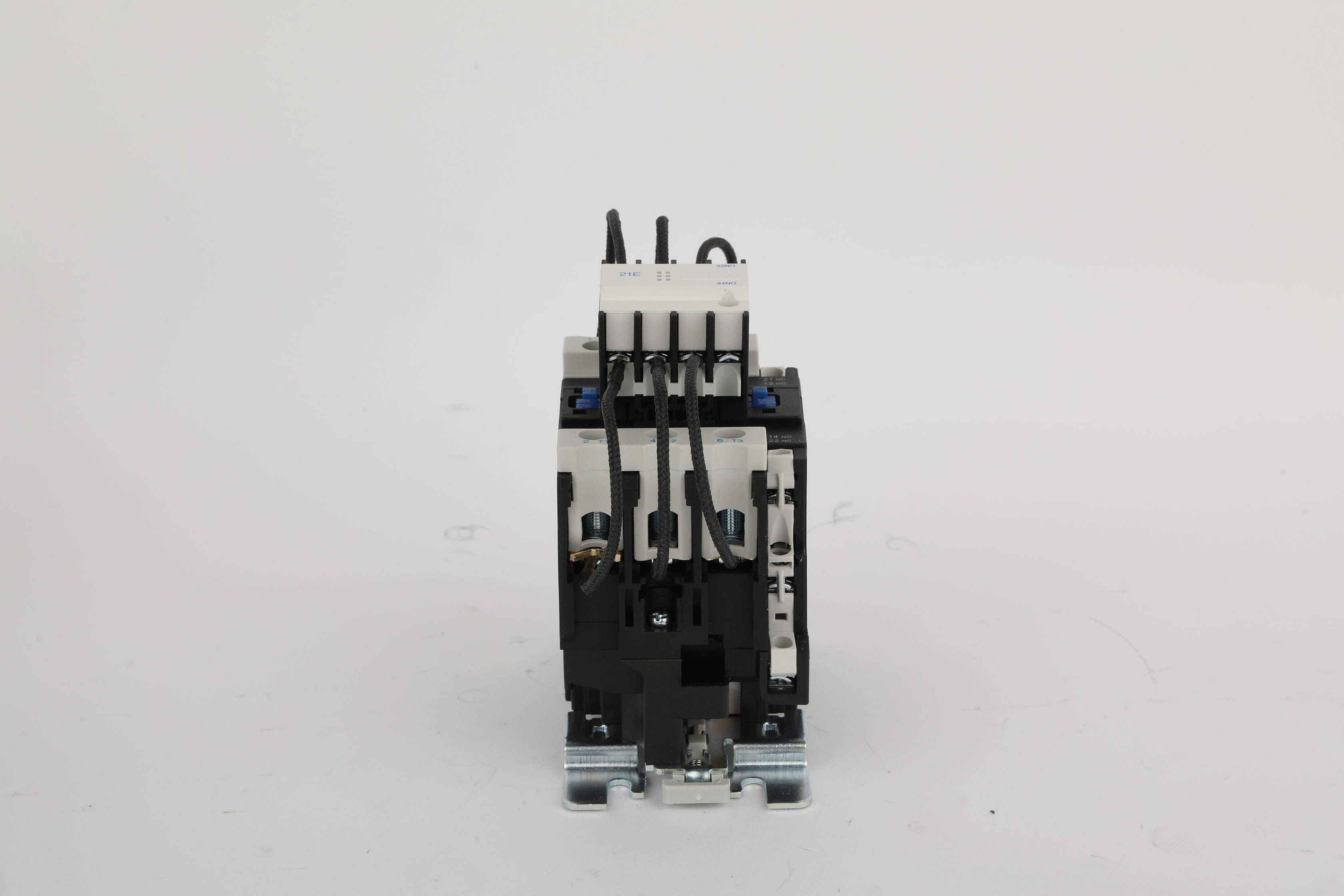

As a mechanical switching device, the contactor is widely used in reactive power compensation due to its low cost, simple structure and high reliability. The contactor achieves switching by electromagnetically driving the contact to close or open. It is suitable for scenarios where the load changes slowly and the switching frequency is low. For example, in a stable distribution system, the contactor can effectively handle resistive or mild inductive loads, and is easy to maintain with a long lifespan. However, when switching inductive or capacitive loads, the contactor may generate arcs and mechanical wear. Especially under frequent operations, the contact points of the contactor are prone to erosion, which directly leads to an increase in contact resistance and energy consumption.

Geyue Electric notes that among all the switching devices, contactors have relatively slower response speeds, typically with response times exceeding several tens of milliseconds. This to some extent limits their application in dynamic compensation. For rapidly changing loads, such as those of inductive loads, the switching delay of contactors may lead to untimely compensation, thereby affecting the quality of electrical energy. Moreover, in high-harmonic environments, the electromagnetic mechanism of contactors may be interfered with by harmonics, which can result in incorrect actions or noise of the electromagnetic mechanism. Therefore, although contactors have advantages in cost-sensitive projects, their limitations require users to carefully consider the load characteristics when selecting equipment and avoid using contactors as switching devices in scenarios with high-speed changing loads or high-impact loads.

The Advantages and Application Fields of Thyristors

As a semiconductor switching device, thyristors are renowned for their lack of contacts, high-speed response, and high reliability. In contrast to contactors, thyristors are particularly suitable for applications in load environments with rapid and frequent switching. By controlling the gate signal, thyristors can achieve zero-voltage switching, effectively eliminating inrush currents and voltage spikes, and accurately compensating for inductive and capacitive loads. For instance, in situations where load fluctuations are frequent, such as in steel mills or automotive production lines, thyristors can complete switching within milliseconds, ensuring real-time optimization of power factor and significantly reducing voltage and current fluctuations in the power grid.

Geyue Electric emphasizes that the advantages of thyristors lie in their long lifespan and low maintenance requirements. Secondly, since thyristors have no mechanical components, they are less susceptible to wear or arc effects compared to contactors. Finally, but not least importantly, thyristors perform stably in high harmonic environments and can withstand certain electrical disturbances. However, thyristors also have disadvantages such as high cost and strict heat dissipation requirements. When applying thyristors for switching in high-temperature or high-current conditions, a heat dissipation device must be equipped simultaneously; otherwise, the thyristors are highly likely to be damaged due to overheating. Additionally, thyristors may generate leakage current under low-load conditions, significantly affecting the switching efficiency. Therefore, before selecting thyristors, it is necessary to carefully evaluate the switching frequency of the load and the thermal management conditions to ensure the balance between economic performance and performance in the reactive power compensation system.

Integration and Optimization Schemes for Compound Switches

The compound switches combine the advantages of contactors and thyristors, achieving optimized switching process through intelligent control. In the initial stage, the compound switch uses the thyristor for zero-voltage switching to avoid current shock; subsequently, the contactor takes on the steady-state current, reducing energy consumption and heat loss. This design makes compound switches suitable for mixed load scenarios, such as industrial systems with both stable-running equipment and frequently fluctuating loads. Geyue Electric has verified in multiple projects that the compound switches can significantly enhance the durability and energy efficiency of the switch, especially in high-impact or high-harmonic environments.

The optimization of the compound switches lies in its adaptive capability, which can automatically adjust the switching strategy according to the load characteristics. For example, in high inductive load scenarios such as motor startup, the compound switches first use thyristors for smooth transition, and then switch to contactors to maintain operation, thereby reducing electrical stress. At the same time, the compound switches solve the heat dissipation problems of pure thyristors and improves system reliability. However, the structures of composite switches are complex, their costs are higher than those of single switches, and they have higher requirements for control logic. Geyue Electric suggests that in cases where the load characteristics are variable or where energy efficiency is strictly required, the compound switches can be the preferred choices. Through integrated design, compound switches can achieve a reduction in long-term operating costs.

As a manufacturer of low-voltage reactive power compensation equipment, Geyue Electric has gained insights through years of practice: The selection of switching devices should be based on comprehensive load analysis and technical economic evaluation. We recommend that users first conduct load characteristic diagnosis, including but not limited to measuring the load type, variation frequency, current harmonics, and temperature conditions, etc. For stable resistive loads, contactors may be sufficiently economical; for rapid dynamic loads, thyristors or compound switches are more preferred. Geyue Electric provides professional customized solutions, through simulation tests and real-time monitoring, to help users match the most suitable switching device type. If you are looking for a suitable reactive power compensation solution provider, please feel free to contact us at info@gyele.com.cn. Our technical team will communicate with you.

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?