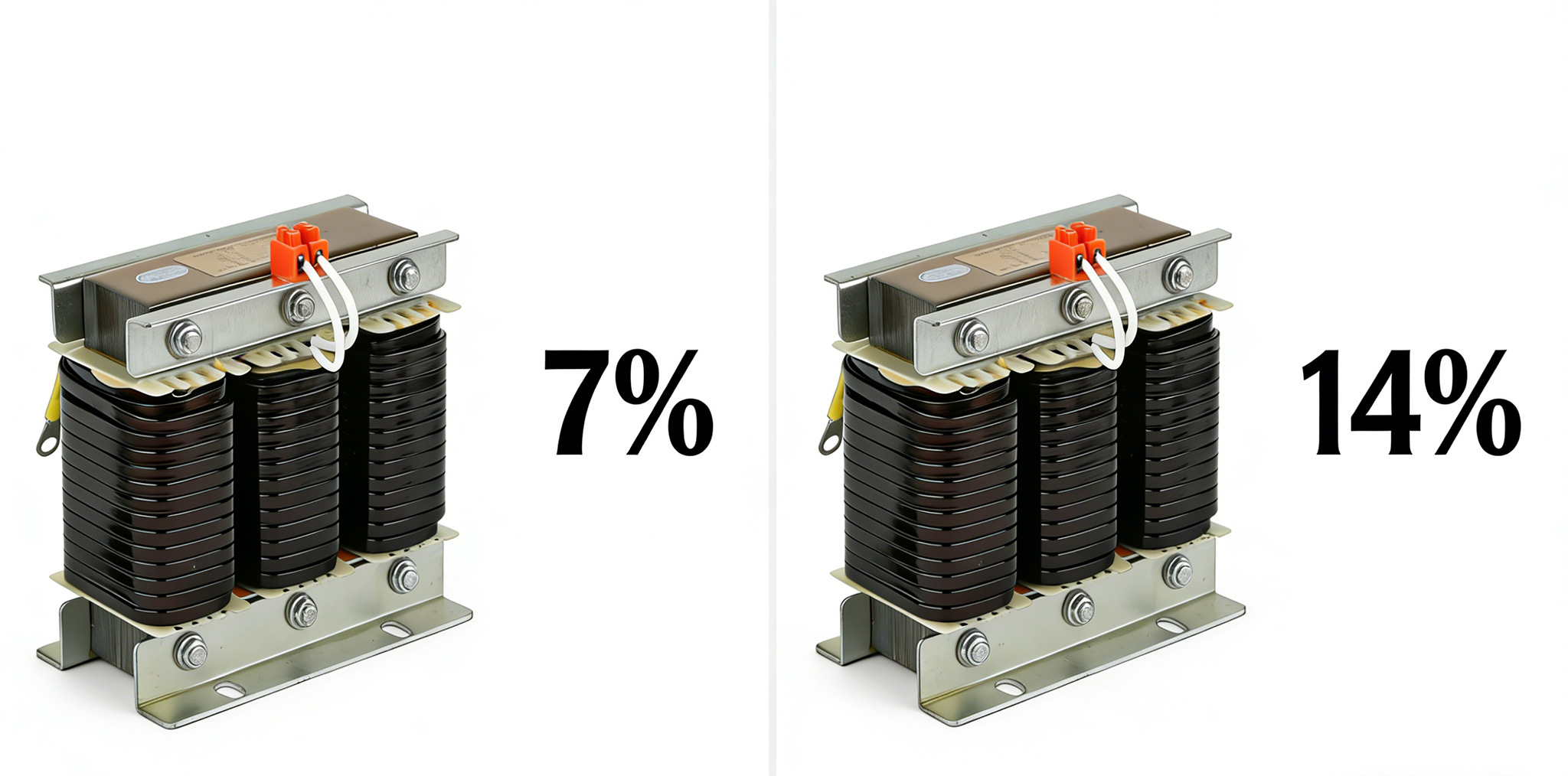

Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

In low-voltage power distribution systems, reactive power compensation and harmonic management are increasingly becoming the top priorities for anchoring power quality. When there are nonlinear loads such as frequency converters and rectifiers in the power grid, the high-order harmonics generated by these loads not only pollute the power grid but also directly threaten the safe operation of power factor capacitors and the entire low-voltage reactive power compensation system. As a leading manufacturer in the field of low-voltage reactive power compensation in China, Geyue Electric clearly understands that choosing the correct reactance rate of the series reactor is the primary technical decision for building a reliable filtering compensation system.

Reactance Rate: The "Tuning Frequency" for Harmonic Control

The reactance rate of the series reactors is not a randomly set parameter. It determines which harmonic the LC circuit composed of the series reactor and capacitors presents a low impedance to. This circuit is like an acoustic resonator cavity, which has an "absorption" effect on harmonic currents of specific frequencies. A circuit with an 7% reactance rate mainly tunes and attenuates the highest content 7th harmonic (350Hz) in the power grid; while a circuit with a 14% reactance rate mainly tunes and attenuates the 5th harmonic (250Hz). The choice of which reactance rate (7% or 14%) for the series reactors depends first on the precise diagnosis of the harmonic spectrum at the site. Incorrect selection not only fails to suppress harmonics but may also cause resonance amplification of specific harmonics, leading to disastrous consequences. Geyue Electric always recommends that before designing a low-voltage reactive power compensation scheme, a professional instrument should be used for power quality measurement, or the harmonic analysis function built into the power factor controller should be utilized to obtain key data, providing practical basis for scientifically selecting a reasonable reactance rate for the series reactors.

The Divergence between 7% and 14% in Typical Application Scenarios

In practical applications, the selection of the reactance rate for series reactors is closely related to the load characteristics. In heavy industry and process industry scenarios dominated by equipment such as frequency converters and medium-frequency furnaces, the harmonic spectrum is typically dominated by the 5th harmonic.In such cases, a series reactor with an impedance rate of 14% should be selected to effectively absorb this harmonic current and protect the capacitor from overcurrent damage. In data centers, commercial buildings, and industrial environments dominated by rectification equipment, the seventh harmonic component is often more prominent. In such cases, a scheme with a reactance rate of 7% would be more suitable. An advanced reactive power compensation system can configure multiple tuned filter branches with different reactance rates to cover the main harmonic spectra. The core power factor controller in the system, through implementing flexible capacitor switching strategies, conducts intelligent coordinated management of all branches. This architectural design is specifically designed to handle complex harmonic environments and ultimately achieve refined management of power quality.

Geyue Electric’s CKSG Series: Every Percentage Point of a Reliable Gene

The accuracy of the reactance rate of the series reactor is only sufficient to be specified in the design drawings. The long-term stability and reliability of the series reactor must be guaranteed by the manufacturer's outstanding manufacturing process. Geyue Electric has launched the CKSG series of low-voltage series reactors, which is specifically designed to meet this demanding requirement. Whether it is a 7% or 14% reactance rate model, our company always uses high-quality imported cold-rolled oriented silicon steel sheets as the core material, and through a unique epoxy resin casting and curing process, the air gap of the core never shifts under vibration and temperature changes, thus safeguarding the lifelong stability of the inductance value. Our series reactors' coils use high-purity oxygen-free copper windings, combined with the H-class insulation system and vacuum impregnation process, so that the series reactors can maintain extremely low temperature rise and operating noise even under high-temperature and heavy-load conditions. This unwavering pursuit of precision is our eternal commitment to every user: every percentage point of reactance rate of our series reactors is truly accurate, serving as a solid hardware foundation for the filtering effect of each tuned filter branch in the reactive power compensation system.

Geyue Electric is committed to providing users with a complete value chain covering professional diagnosis, precise selection, high-quality component supply and intelligent control from a system perspective. Our technical team can analyze the load characteristics of your power grid and recommend the optimal 7% or 14% reactance rate configuration scheme for you, or even design a more complex hybrid filter compensation cabinet for you. Choosing the correct reactance rate is the scientific starting point to avoid harmonic risks; choosing Geyue Electric is giving the entire power quality governance system a reliable life. Please send your inquiry about low-voltage reactive power compensation to info@gyele.com.cn. Let us jointly protect the purity and efficiency of your power grid with the solid protection of our CKSG series series reactors and the professional system design capabilities.

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?