How Can Anti-Burst Measures Be Designed to Ensure the Safety of Reactive Power Compensation Equipment and Personnel to the Greatest Extent?

In the field of industrial power systems, low-voltage reactive power compensation is a key aspect for enhancing energy efficiency and stabilizing the power grid. However, the potential risk of capacitor rupture during faults has always been a significant concern for every manufacturer and user of low-voltage reactive power compensation equipment. Geyue Electric, as a key player in the low-voltage reactive power compensation industry for a long time, we deeply understand that safety is the foundation of all technological innovations. Capacitor rupture is not an accident; it is often the result of the accumulation of internal faults and the lack of external protection. Therefore, a scientific, comprehensive and forward-looking design of measures to prevent rupture is not only the core value of Geyue Electric's products, but also a manifestation of our solemn commitment to the safety of equipment and personnel. This requires us to build an unbreakable safety barrier from three dimensions: pressure relief, fault prediction and physical isolation.

Pressure Relief and Container Structure Design

The arc generated by an internal fault in a capacitor will instantly decompose the dielectric, produce a large amount of gas, cause a sharp increase in pressure, and eventually break through the weakest point of the shell, resulting in a violent explosion. Therefore, the first priority of safety design is to provide a controllable release path for these inevitable internal pressures.

Conventional capacitors typically employ a welded sealed structure to completely confine the pressure within the casing. Once a fault occurs, the casing acts like a miniature high-pressure bomb and can only release energy through a tearing explosion. To fundamentally address this issue, Geyue Electric has taken the lead in adopting products with a pressure-pull-off explosion-proof design in key components. The ingenuity of this design lies in the pre-set, precisely calculated mechanical weak point at the top of the capacitor casing. When the internal pressure exceeds the safety threshold, this weak point will be neatly pulled apart to form a directional pressure relief channel. The high-pressure gas, carrying ionized substances, is then discharged through this channel, effectively preventing the secondary injury caused by the scattering of metal fragments from the casing. This design enables the orderly release of energy, transforming the destructive explosion into a controlled pressure relief action, which serves as the first and most crucial physical barrier to ensure personnel safety.

Fault Detection and Early Warning

Passive defense is undoubtedly important, but proactive early warning can prevent problems before they occur. Eliminating potential safety hazards at their infancy is a higher-level safety philosophy, which relies on a set of acute and reliable fault detection & early warning system.

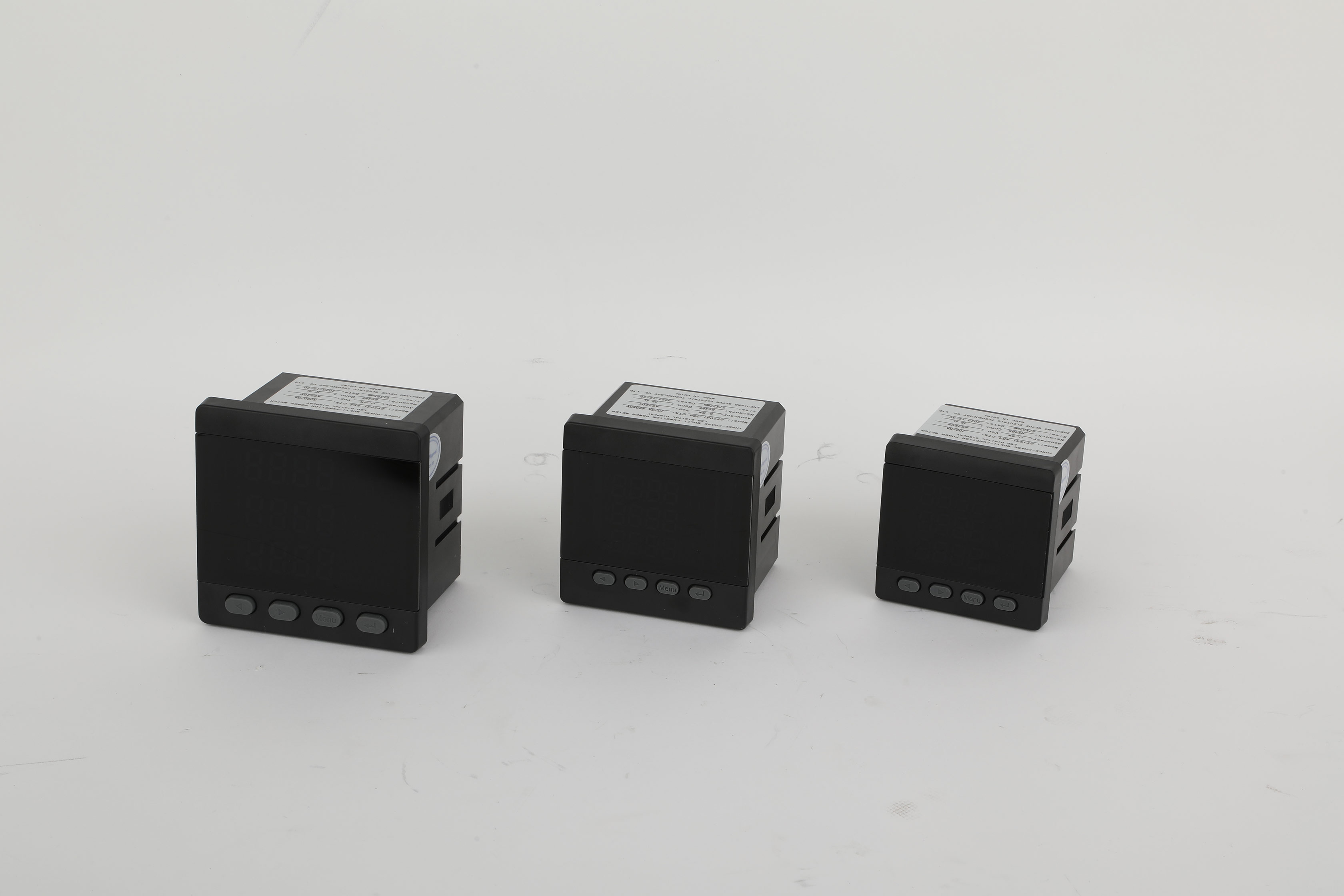

The aging and failure of capacitors is a gradual process, often accompanied by symptoms such as overcurrent and overheating. An excellent reactive power compensation controller is not merely responsible for issuing simple switching instructions. An excellent reactive power compensation controller must play the role of a system doctor, capable of real-time monitoring of the current and temperature changes in each capacitor branch. When the reactive power compensation controller detects an abnormal increase in current or a continuous rise in temperature, the system should be able to issue an alarm promptly and automatically disconnect that capacitor from the power grid. This is like triggering a smoke alarm and automatically starting the sprinkler system at the early stage of a fire, preventing the fire from spreading and causing damage. Geyue Electric integrates such intelligent detection technologies deeply in its design to ensure that the system not only responds quickly but also provides warning information, giving maintenance personnel sufficient time to intervene and carry out maintenance, thus completely blocking the failure before it turns into a rupture.

Physical Isolation and System-Level Protection

The protection of any single component cannot guarantee 100% safety. Therefore, we must consider the entire system as a whole and implement physical isolation and structural protection to set up the final barrier for possible extreme situations.

Even if each individual capacitor is equipped with an explosion-proof device, the high-temperature gas and substances released during its pressure relief may still pose a threat to other adjacent equipment or cause inter-phase short circuits. Therefore, in the design of the complete compensation device, we advocate and provide an independent insulating protective cover for each capacitor. This protective cover not only effectively blocks the arcs and particles released during pressure relief, but also has insulation and flame-retardant functions, preventing the expansion of the fault. Further, in the design of the cabinet structure, the construction of the pressure relief channel should be fully considered. For example, install the capacitor bank in an independent isolation room, and set up a dedicated pressure relief channel on the top or rear of the cabinet to safely direct the high-temperature and high-pressure gas generated during the fault to an area outside the equipment where no one is present. This system-level protection concept ensures that even in the most extreme component failure, the destructive energy can be constrained and guided, maximizing the guarantee of absolute safety for the entire distribution room and the on-site operators.

Our view at Geyue Electric is that explosion-proof measures are not an isolated function added to the capacitor, but a core element throughout the entire process of product design, production, manufacturing and technical services. Our company firmly believes that true safety stems from the relentless pursuit of product details. From selecting strictly certified explosion-proof capacitors, to integrating intelligent warning functions into the controller, to the carefully designed isolation and ventilation structure of the cabinet, every single step mentioned above, including those not explicitly listed, has been repeatedly verified and tested by our technical team. Through continuous technological innovation and rigorous safety design, Geyue Electric will jointly build a solid and reliable protective barrier in the low-voltage reactive power compensation field, ensuring that the path to improving power quality is based on absolute safety. If your reactive power compensation system requires anti-burst protection, please feel free to mail our engineering team via info@gyele.com.cn.

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?