How to Scientifically Select an AC Contactor or Compound Switch to Match an Intelligent Reactive Power Automatic Compensation Controller?

Introduction

In low-voltage reactive power compensation devices, the switching commands of intelligent controllers must be implemented through actuators. AC contactors and combined switches are currently the most suitable technical solutions. This article systematically analyzes the operating principles, performance differences, and project applicability of these two solutions.

Essential Differences in Operating Principles

AC contactors utilize an electromagnetic mechanical structure, using the magnetic force generated by energizing the coil to actuate the contacts, thereby connecting and disconnecting the circuit. This operation is accompanied by a noticeable mechanical sound and arcing. Compound Switch utilize a hybrid "thyristor + contactor" design. The thyristors first conduct when the voltage crosses zero, then the contactors complete the main circuit connection, and finally the thyristors are deactivated. This operating mechanism achieves true inrush-free switching.

Comprehensive Comparison of Technical Performance

Contactor switching characteristics indicate that contactor operation generates a closing inrush current of 20-40 times the rated current. While this can be suppressed with current-limiting reactors, it can still impact the power grid and capacitors. Compound Switch achieve zero-crossing switching, limiting the inrush current to less than twice the rated current, significantly extending equipment life. In terms of response speed, contactors require 10-20ms to complete actuation, while the thyristor in an inrush-free switching switch responds within 1-2ms, making it particularly suitable for applications with rapidly fluctuating loads.

Economic Analysis

AC contactors offer a significant price advantage, with procurement costs only one-third to one-half of those of inrush-free switches. However, frequent switching increases maintenance costs significantly. While the initial investment for inrush-free switches may be higher, their electrical lifespan of over 100,000 cycles and near-maintenance-free operation offer superior economic benefits over their lifetime. Therefore, in scenarios with more than 50 daily switching operations, inrush-free switches are the more economical choice.

Analyzing Typical Application Scenarios

For applications with impact loads such as metallurgy and welding, a no-inrush current switching solution is recommended. Its fast response effectively tracks reactive power changes and avoids system voltage fluctuations. For commercial buildings and residential areas with fewer than 20 switching cycles per day, high-performance capacitor switching contactors are the most cost-effective option. In environments with severe harmonics (THvD > 8%), an anti-harmonic compensation device with a 7% reactance ratio, combined with a dedicated contactor, should be prioritized.

Installation and Commissioning Key Points

When installing contactors, ensure adequate heat dissipation clearance. It is recommended that adjacent components be at least 20mm apart. For inrush current switches, pay special attention to heat dissipation conditions. If the ambient temperature exceeds 40°C, derating is required. Controller parameter settings must match the actuator: When using contactors, set a switching delay of 1-2 seconds, while for inrush current switches, a setting of 0.5-1 second is acceptable. All electrical wiring must be secure and reliable to prevent overheating damage caused by excessive contact resistance.

Maintenance and Repair

Contactors should be inspected for contact wear every six months. Replace contacts when the silver point thickness is less than 1/3 of its original thickness. For inrush current switches, monitor heat dissipation and regularly clean accumulated dust to ensure proper fan operation. Regardless of the solution, it's recommended to check capacitor capacity changes monthly and replace capacitors if capacity loss exceeds 5%.

How to Choose the Right Combination

The selection decision should comprehensively consider the following factors: load frequency, investment budget, maintenance capabilities, and power quality requirements. Generally speaking, if the budget is sufficient and the application is demanding, a non-inrush current switch should be selected. If the budget is limited and the application is infrequent, a dedicated contactor should be selected. For critical applications, a hybrid solution can be designed, using contactors for baseload loads and non-inrush current switches for fluctuating loads, achieving the optimal balance between economy and reliability.

Conclusion

AC contactors and inrush-free switches each have their own applications, and there's no absolute superiority or inferiority. The right choice requires a comprehensive assessment based on actual operating conditions, taking into account initial investment and operating and maintenance costs. With the continuous advancement of technology, we believe that more innovative solutions will emerge in the future to meet the personalized needs of different users.

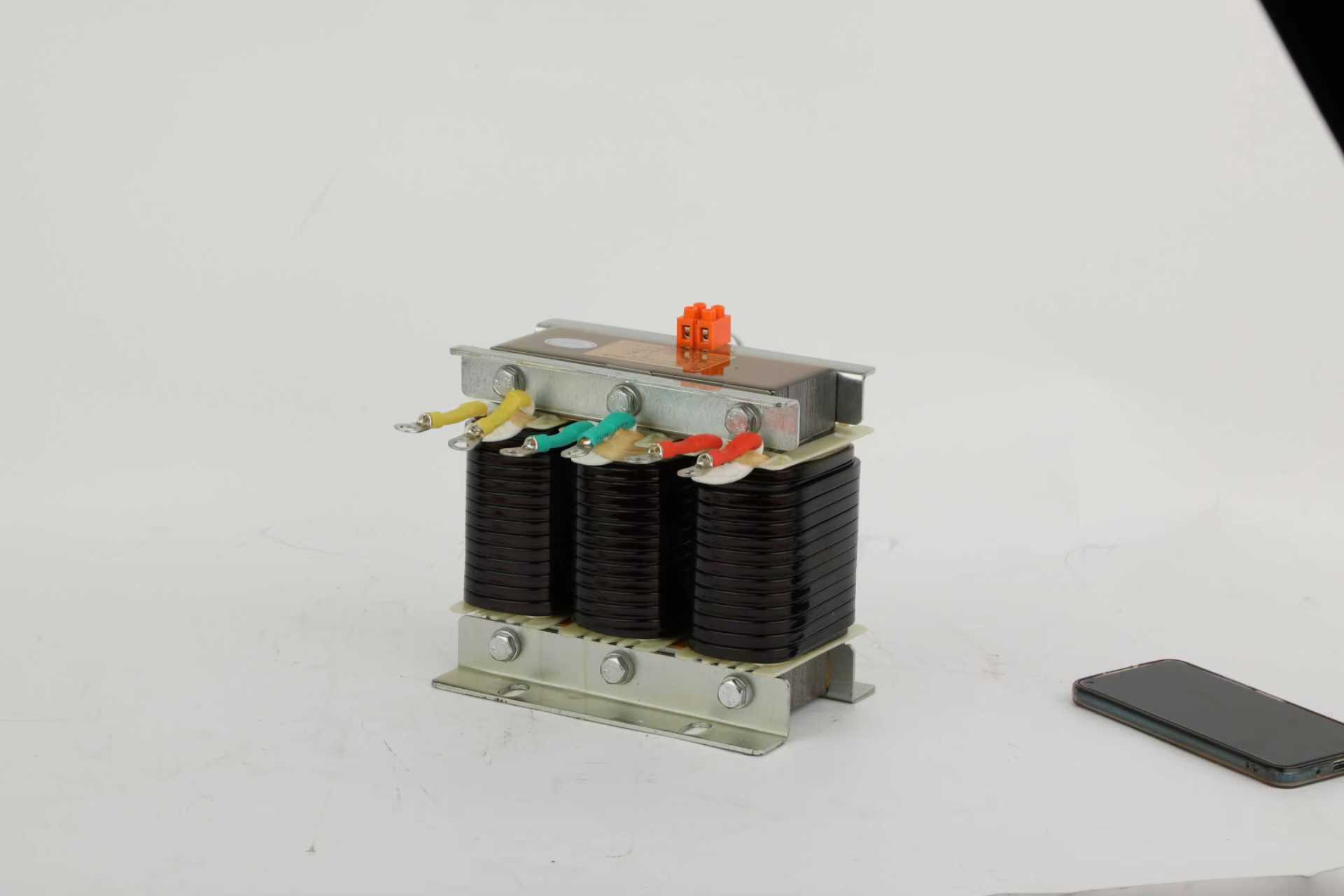

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

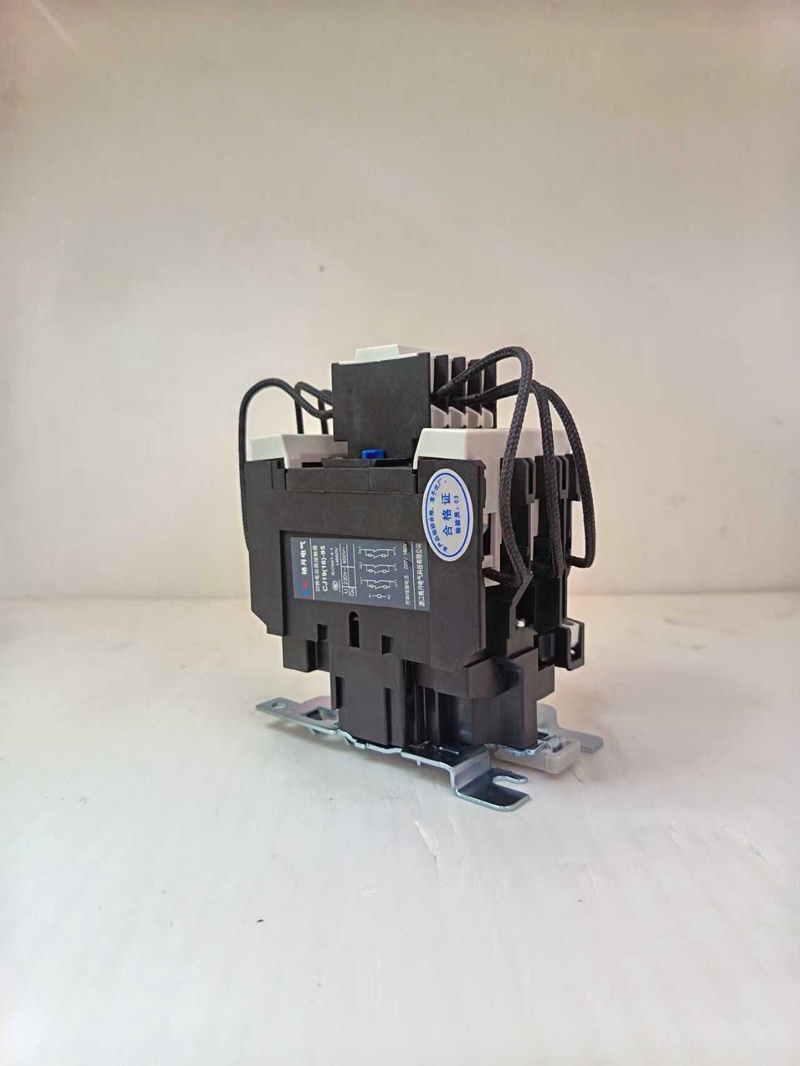

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?