How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

Foreword

Having worked in the low-voltage electrical appliance manufacturing industry for over two decades, we've witnessed numerous product upgrades and replacements, but the CJ19 series AC contactor has consistently maintained its place in the market. This product, specifically designed for capacitor switching, has been in service in power systems across China for nearly two decades since its introduction in 2003. Over the years, we've collected tens of thousands of operational data points and user feedback, providing invaluable firsthand information to continuously improve our product. We remember when we first started, the product's functions were relatively basic; now it has been upgraded to a smart version. We deeply understand that a good product must not only be functional but also stand the test of time. Now, with the construction of smart grids, we are continuously improving our product to keep pace with the times.

Technical Features and Innovations

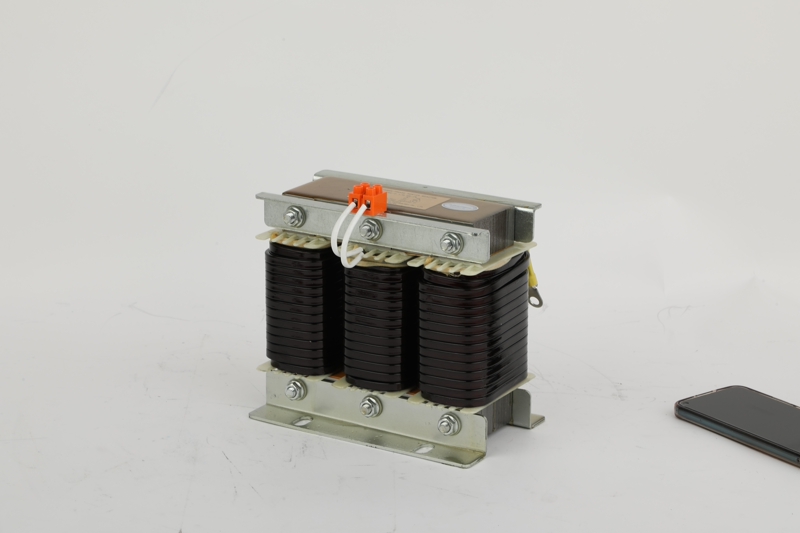

When developing the CJ19, we encountered many technical challenges. The biggest hurdle was the inrush current problem generated during capacitor switching. We spent two full years conducting material experiments before finally selecting silver tin oxide as the contact material. This material indeed has excellent arc resistance, allowing the contacts to last longer. For the arc extinguishing system, we came up with the idea of multi-layer grid arc extinguishing.

Real-world Application Cases

Welding equipment typically requires repeated starts and stops during operation, a working mode that severely tests the AC contactor contact system. Our three-month field tracking test revealed that even with hundreds of operations per day, the CJ19's contact wear remained within the design limits. Particularly in production processes with concentrated spot welding operations, where equipment start-stop intervals are sometimes only a few seconds, extremely high demands are placed on the contactor's electrical and mechanical lifespan. Actual operating data shows that even under such demanding conditions, the CJ19 maintained stable performance, with its contact erosion levels far below industry standard allowable values. We recorded operational data over three months, showing that the contact wear was entirely within the expected range. Our proudest achievement is our application in a large-scale photovoltaic power station in Northwest China, where the temperature difference between day and night reaches 30 degrees Celsius, and sandstorms are severe year-round. We specifically enhanced the enclosure protection level, adopting the IP54 protection standard, and added a special dustproof design to the contacts. In five years of operation, only routine maintenance has been performed, fully demonstrating the product's adaptability to harsh environments. These successful cases not only validate the product's reliability but also provide valuable first-hand data for our subsequent product improvements.

Market Feedback and Improvement

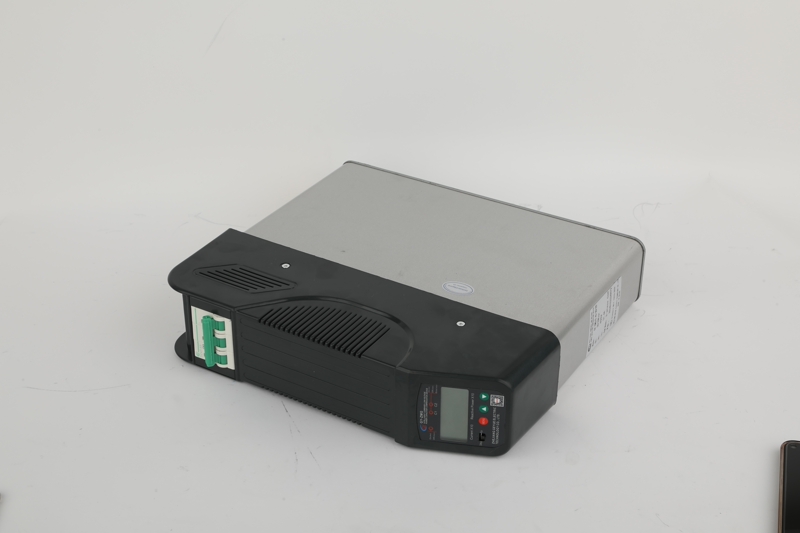

The market is the best test of a product. For twenty years, we have continuously collected user feedback from different stages of power generation, supply, and consumption. Maintenance personnel at a 500kV substation reported that the CJ19 remained in good condition after five years of continuous operation, requiring only routine maintenance. Based on this valuable feedback, we have continuously optimized product design. This function records the cumulative number of operations, facilitating users' prediction of maintenance cycles. These thoughtful improvements have earned the CJ19 a good reputation in the market, resulting in a steady increase in market share. We also regularly organize user exchange meetings to collect issues encountered during use; this firsthand data provides crucial information for continuous product improvement.

Future Outlook

Facing the trend of intelligent and digital development in the power industry, we are developing a new generation of intelligent AC contactors. The new products will integrate more types of sensors to achieve real-time monitoring and data analysis of operating status.

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?