Why do Hydrogen Energy Electrolyzers Need Customized Reactive Power Compensation Devices?

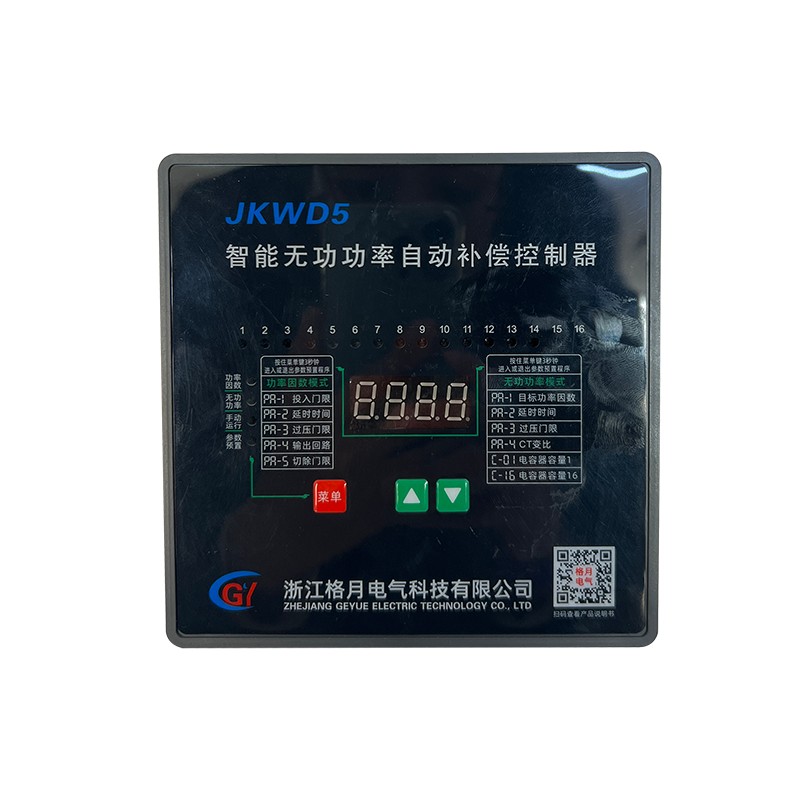

In the wave of green energy transformation, hydrogen energy, as a clean energy carrier, is experiencing rapid development. The electrolyzer, as the core equipment of the hydrogen production system, requires stable operation to meet specific requirements for the power quality of the power grid. As a manufacturer of low-voltage reactive power compensation equipment, Geyue Electric believes that customized reactive power compensation devices are the key technical support for ensuring the efficient and stable operation of the electrolyzer. The author of this article will deeply explore this issue from three dimensions: the characteristics of the electrolyzer, the impact on the power grid, and the solutions.

The load Characteristics of Electrolytic Cells Put Forward Special Requirements for Reactive Power Compensation

The hydrogen electrolyzer uses high-power rectification technology to convert alternating current into direct current. This process generates a large amount of harmonics and reactive power demands. Unlike traditional industrial loads, the reactive power variation of electrolytic cells has the characteristics of rapidity and randomness. Especially during the startup and power regulation processes of the electrolytic cells, the reactive power can be observed to have significant fluctuations. This characteristic makes it difficult for standard reactive power compensation devices to meet their compensation requirements.

During the operation of the electrolysis cell, characteristic harmonics are generated, mainly from the harmonics produced by 6-pulse or 12-pulse rectifiers. These harmonics can cause distortion in the grid voltage and affect the normal operation of other equipment. Therefore, it is very necessary to integrate the function of active filtering in customized reactive power compensation devices to precisely monitor and manage specific harmonic spectra. Under our company's monitoring, the operation data of a large-scale green hydrogen project showed that without installing a dedicated compensation device, the total harmonic distortion rate of the grid during the operation of the electrolysis cell exceeded 15%, while after adopting the customized compensation, it dropped below 4%.

The temperature control system and auxiliary equipment of the electrolyzer will also generate additional reactive power demands. Although these auxiliary devices have smaller power, their operating characteristics differ from those of the main electrolyzer, and require compensation devices to have multi-objective coordinated control capabilities. Customized compensation equipment can compensate for the main equipment and auxiliary equipment separately through a zone-based compensation strategy, thereby ensuring the stable operation of the entire hydrogen production system.

The Specific Requirements of the Grid Connection Point Necessitate Targeted Solutions

The installation location of the electrolysis cell is usually in areas with abundant renewable energy resources. The grid structure in these areas is relatively weak and the short-circuit capacity is low. When the grid impedance is high, as long as there is a change in reactive power, the voltage will experience severe fluctuations. Therefore, in the installation location of the electrolysis cell, the designers of the power system need to specially design and customize compensation devices based on the short-circuit capacity and impedance characteristics of the grid to ensure the stability of the voltage even when the grid conditions are weak.

The grid connection regulations impose strict requirements on the electrical quality of electrolyzer projects. Power grid companies in different regions have strict regulations for indicators such as harmonic content, power factor and voltage fluctuation of the local power system. Therefore, the operational indicators of customized compensation equipment need to fully comply with the grid connection technical requirements of the local power grid to avoid being subject to power restrictions or fines due to electrical quality issues.For example, an offshore hydrogen energy project once encountered a problem of limited operating power due to excessive voltage fluctuations in the system. After entrusting our company, Geyue Electric, to handle the issue, our engineers customized and installed the compensation equipment, and the problem was finally completely resolved.

The expansion requirements for the electrolysis plant also need to be considered in advance. Hydrogen production projects usually adopt a phased construction approach. The compensation equipment needs to reserve space for capacity expansion and capability upgrade. Customized equipment is designed in a modular manner, which can gradually increase the compensation capacity as the electrolysis plant expands, avoiding redundant investment and equipment waste.

Technological Innovation and Engineering Practices of Customized Compensation Devices

In view of the load characteristics of the electrolytic cell, the customized compensation device needs to adopt advanced control strategies. Based on the model predictive control algorithm, it can predict the power changes of the electrolytic cell in advance and achieve forward-looking compensation of reactive power. The adaptive control technology can automatically adjust the control parameters according to the changes in grid parameters to maintain the best compensation effect.

The device topology structure needs to be optimized for the application of electrolytic cells. Using a multi-level inverter topology can reduce switching losses and improve compensation efficiency. Redundant design ensures that the device can still operate when some modules fail, thereby enhancing system reliability. After a large green hydrogen project adopted a customized SVG device, the availability rate of the compensation equipment reached over 99.9%.

The performance of the design system in terms of environmental adaptability is particularly important. The installation location of the electrolytic cell is usually in a harsh environment, so the compensation device needs to have stronger heat dissipation capabilities. In the power system, the adoption of liquid cooling technology and high-temperature components can meet the operational requirements of the electrolytic cell in a high-temperature environment. The use of anti-corrosion design enables the electrolytic cell to resist salt fog corrosion in coastal areas, thereby ensuring the long-term stable operation of the equipment.

The unique load characteristics of hydrogen electrolyzers in the hydrogen energy system make it undeniable that hydrogen electrolyzers have a specific demand for reactive power compensation devices. Customized solutions not only can solve the problem of power quality but also can improve system operation efficiency and reduce operating costs. With the accelerated development of the green hydrogen industry, customized reactive power compensation technology will play an increasingly important role. Geyue Electric will continue to deepen technological research and development, providing higher-quality power quality solutions for the hydrogen energy industry, and helping to achieve global energy green transformation. We believe that through technological innovation and engineering practice, customized reactive power compensation devices will provide a solid guarantee for the development of the hydrogen energy industry. If your new project requires a customized reactive power compensation solution, please feel free to contact us via info@gyele.com.cn.

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

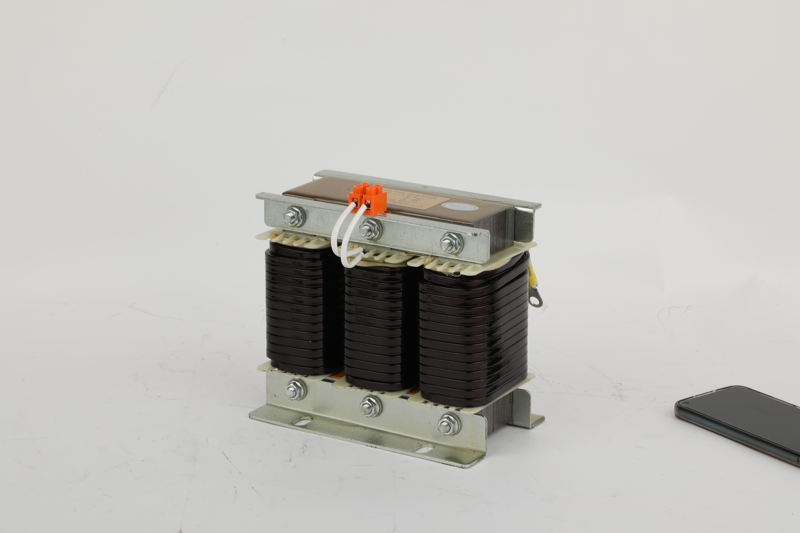

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?