How To Ensure That Series Reactor Is Delivered To Customers Efficiently?

Preface

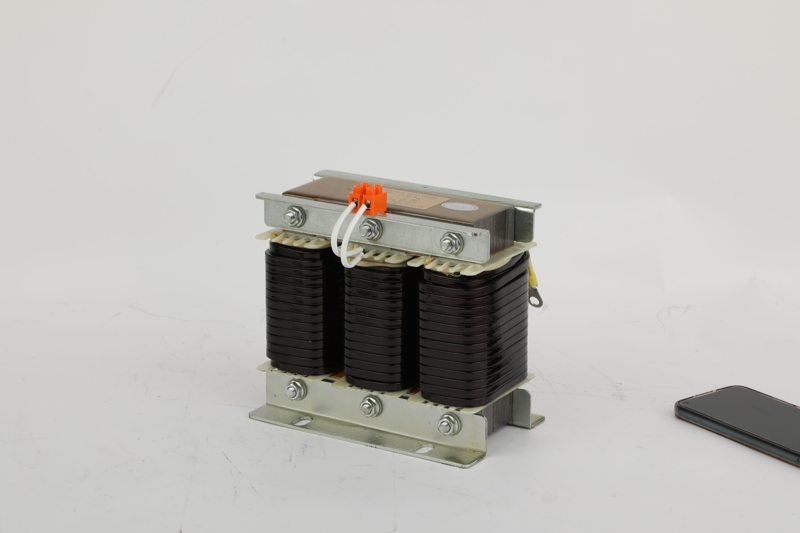

Our company has established a comprehensive distribution system and service guarantee mechanism. We have developed differentiated delivery plans tailored to the needs of customers in different regions of China, ensuring that all customers enjoy convenient and efficient door-to-door service. For customers in nearby areas, we use our own professional fleet to deliver goods, ensuring safe and timely transportation. For orders shipped across provinces, we use carefully screened, high-quality logistics partners for dedicated delivery, ensuring fully traceable logistics services. We need to ship a batch of series reactors to a customer today. All reactors come with a full twelve-month warranty, and any quality issues arising during this period will be promptly and professionally resolved. Our product quality control system ensures an excellent failure rate of less than 0.01%. The reactors are manufactured using high-quality, high-grade silicon steel sheets and an advanced vacuum impregnation process. These technical features guarantee long-term stability and reliability.

Nationwide Delivery Service

We have established a systematic delivery service system to provide comprehensive transportation support. For orders within a 300-kilometer radius, we arrange dedicated drivers and dedicated delivery vehicles for door-to-door delivery. All delivery vehicles are equipped with professional anti-vibration mounts and waterproof packaging materials to protect the series reactors from damage during transportation. To meet the needs of customers in interprovincial regions, we have established long-term partnerships with well-known logistics companies such as SF Express and Deppon, using dedicated logistics channels to ensure safe and timely delivery of goods. We implement a full-process logistics tracking system, allowing customers to track the location of their goods in real time through a dedicated tracking channel and schedule specific delivery times in advance. Each package comes with a detailed installation manual and acceptance documents, allowing customers to conduct an on-site visual inspection upon signing to ensure the product is intact. We also provide an arrival confirmation service to ensure a complete and closed-loop delivery process.

Product Quality Assurance System

We offer a 12-month warranty on all our reactors. Any quality issues arising during this period will be promptly and professionally resolved. When customers require technical support, our dedicated team guarantees a response and resolution within 24 hours. Customers can register repair requests through our dedicated service hotline, and we will arrange for a repair technician to conduct on-site inspections or replace the equipment, depending on the specific situation. Our series reactors utilize a fully automated winding process and vacuum varnishing technology. These advanced processes ensure that the insulation performance meets Class H standards. Long-term operational data statistics show that our product's average annual failure rate remains at an excellent 1.2% per 10,000 units. We have established a comprehensive quality traceability system, with each product individually numbered, enabling traceability from raw materials to finished product. We also provide customers with regular equipment maintenance reminders to help them optimize product maintenance and usage.

Reactor Technical Advantages

Our reactors are manufactured from high-grade, cold-rolled silicon steel sheets with a thickness of 0.23mm. This premium material reduces core loss by 45% compared to conventional materials. The winding conductors utilize double-layer polyester enameled wire, which offers excellent insulation and temperature resistance, enabling the product to withstand temperatures up to 180°C. The entire structure undergoes rigorous vibration testing and can withstand vibrations up to an amplitude of 0.2mm, making it suitable for stable operation in a variety of harsh industrial environments. The product's protection level meets IP54 standards, effectively protecting against the effects of dust and moisture. We also factor heat dissipation into our product design, improving heat dissipation efficiency by 30% through optimized structural design. All products undergo rigorous testing to ensure that all performance indicators meet design requirements.

After-Sales Service Process

We create a dedicated service profile for each customer, detailing each device's operating data and maintenance history. Our service team regularly visits customers to understand the equipment's actual operating status and provide timely reminders about maintenance. We have developed a remote monitoring system that provides real-time visibility into the series reactor's operating temperature and vibration parameters. When the system detects abnormal data, it automatically sends alerts. Our maintenance team, equipped with specialized testing equipment and tools, can complete on-site troubleshooting within two hours of receiving a repair request. We also provide equipment operation analysis reports to help customers better understand their equipment's condition. For equipment requiring maintenance, we offer genuine parts replacement services to ensure optimal operation.

Continuous Improvement Plan

We analyze delivery data monthly and, based on the results, continuously optimize transportation routes and delivery plans, reducing average delivery time to 3.5 days. We continuously improve our packaging materials, and the latest moisture-proof and earthquake-resistant composite structure has reduced the transport damage rate to 0.5 per 10,000 units. We have established an electronic data exchange system with logistics companies to share vehicle location information and estimated arrival times in real time. We have also established a customer satisfaction feedback mechanism to regularly collect customer feedback and improve service quality. Through continuous technological innovation and service optimization, we continuously improve the customer experience and ensure that every customer receives high-quality service.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.