How Can Industrial Compensation Cabinets Improve Power Quality Through Core Accessories?

Preface

In industrial power distribution systems, reactive power loss and harmonic pollution are key factors that lead to low power utilization, reduced equipment life and rising power costs. As the core device for power quality management, the performance of the compensation cabinet is determined by the technical coordination of the four major accessories: capacitor bank, series reactor, dynamic compensation controller and explosion-proof discharge resistor. This article will objectively explain the technical principles, functional positioning and system integration logic of each accessory.

Core Functional Positioning of the Compensation System

The core task of the compensation cabinet is to achieve power factor correction and harmonic suppression of the power grid. When the power factor is lower than 0.9, the line loss rate will increase by 8%-15%, and at the same time trigger the power supply department's power adjustment fee fine (about 3%-8% of the total electricity bill). Harmonic distortion rate (THD) exceeding 5% will cause additional heating of the motor, malfunction of electronic equipment and reduced transformer efficiency. The national standard GB/T 15576-2020 stipulates that the lower limit of the power factor for industrial users is 0.9, and the IEEE 519-2014 standard requires THD to be controlled within 5%.

Command Mechanism of Dynamic Compensation Controller

The Automatic Power Factor Controller collects the grid voltage and current phase difference in real time through a high-speed sampling circuit with 128 points/cycle. When a power factor fluctuation caused by a sudden load change (such as less than 0.8) is detected, its embedded ARM processor completes the Fourier transform calculation within 20ms and outputs accurate power capacitor switching instructions. The built-in zero-crossing switching technology of the controller ensures that the switching action is executed at the voltage zero point to avoid inrush current shock. The core parameter requirements include: response speed ≤50ms (national standard upper limit 200ms), compensation capacity error ±0.5kvar. The 5G communication module supports remote modification of parameter thresholds and receiving fault alarms.

Technical Characteristics of Smart Capacitor Banks

Smart capacitor banks achieve power factor correction of power grids by providing capacitive reactive power. Its core medium uses a 3.8-micron-thick metallized polypropylene film, and uses split-type evaporation technology to control the self-healing area of the medium within 2 square millimeters when a single point is punctured. The capacitor is equipped with a pressure release structure. When the pressure inside the shell reaches 0.12 MPa, the explosion-proof cover ruptures directionally to achieve pressure relief protection. The capacity configuration adopts a stepped classification design, usually including 8 groups of different capacity units, such as 5 kvar, 10 kvar and 20 kvar, and the minimum compensation step is 5 kvar. In a 380-volt power grid environment, when a 30 kvar power capacitor bank is switched on for a motor with a rated power of 100 kW, the system power factor can be increased from 0.75 to 0.94, while reducing the line current by 28.4%. It should be emphasized that the capacitor bank must be operated in series with a filter reactor, otherwise the harmonic current will cause the medium to overheat and fail.

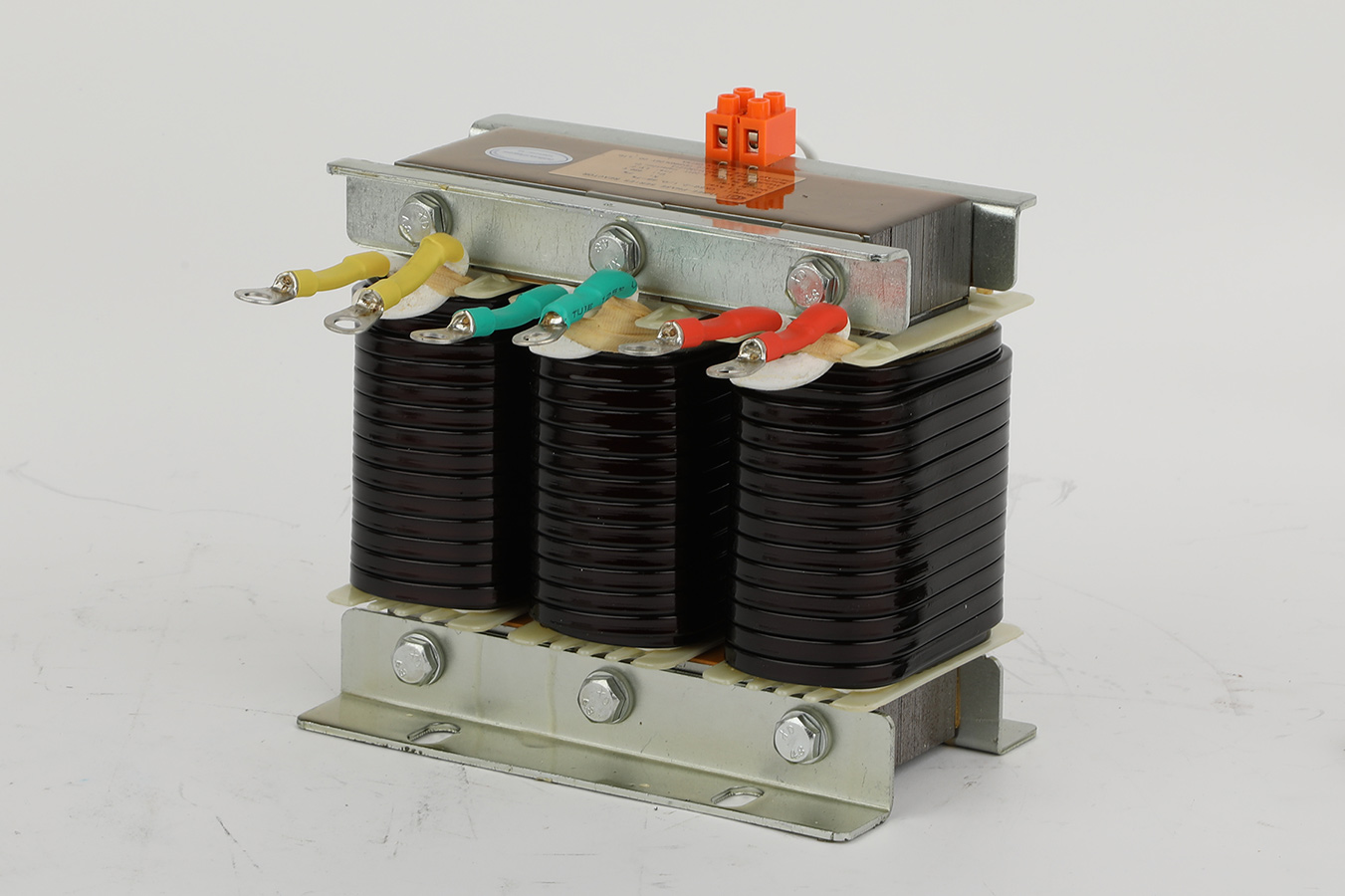

Harmonic Control Principle of Filter Reactor

Filter reactor suppresses harmonics in specific frequency bands based on inductive reactance characteristics. The core design uses a 7% reactance rate to reduce the resonant frequency to 189 Hz, effectively avoiding the 150 to 650 Hz harmonic frequency band commonly generated by industrial equipment. It shows a significant impedance enhancement effect on the 5th harmonic. At a frequency of 250 Hz, the impedance value can reach more than 33 times that of the fundamental wave, suppressing the total harmonic distortion rate to less than 8%. The series reactor winding is vacuum cast with Class B insulating epoxy resin, and the layers are isolated with NOMEX insulating material to ensure that the temperature rise does not exceed 65 Kelvin; the built-in 130 degrees Celsius temperature fuse directly cuts off the circuit when overheating. The inductive reactance is essentially manifested as a blocking effect on high-frequency harmonic currents, and simultaneously reduces the harmonic components flowing through the parallel capacitor by more than 60%. This performance indicator meets the mandatory specifications of the IEC 60076 international standard for power reactors.

Safe Operation Logic of Discharge Resistors

The discharge resistors are responsible for discharging the residual voltage after the capacitor is powered off. A dual-channel structure with a main resistor of 100 kilo-ohms/5 kilowatts in parallel with a backup resistor is adopted, and the surface heat dissipation grid controls the power density below 1.5 watts/square centimeter. When the ambient temperature reaches 45 degrees Celsius, the axial flow fan is automatically activated to enhance heat dissipation. The system can reduce the residual voltage of the 400-volt grid capacitor from a peak of 565 volts to a safety threshold of 50 volts within 3 seconds, which meets the 75-volt upper limit specified in IEC 60831. The mechanical interlock device automatically connects the discharge circuit before the cabinet door is forced to open to ensure the safety of personnel operation.

System Integration and Performance Verification Standards

The complete compensation system must be verified through a three-level verification procedure. During the factory test phase, a 10-second withstand voltage test at 1.25 times the rated voltage and 50 continuous switching impact tests are carried out, with a switching interval of no more than 2 seconds. During on-site commissioning, the power factor target value must be set in the range of 0.92 to 0.98, and the overvoltage protection threshold is configured to 440 volts with an error tolerance of ±5 volts. Operation monitoring requires the system to continuously meet three core indicators: monthly average power factor ≥ 0.95, total harmonic distortion rate ≤ 5%, and voltage fluctuation rate < 2%. When the system detects that the power factor fluctuation exceeds 0.1 or the total harmonic distortion rate rises by more than 2%, the capacitor capacity configuration and the reactor parameter matching status must be checked immediately.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?