How Do We Properly Size a Detuning Reactor to Ensure Capacitor Protection without Compromising Compensation Capacity?

In modern power systems, harmonic pollution has become a hidden threat to the safe operation of low-voltage reactive power compensation devices. As a professional manufacturer of low-voltage reactive power compensation equipment in China, Geyue Electric has truly realized that many customers face a dilemma when applying self-healing shunt capacitors: they need to effectively suppress the amplification of harmonics to protect the capacitors, while also ensuring that the fundamental power compensation capacity is not lost. Regarding how to maintain the balance between these two aspects, properly sizing a detuning reactor plays a crucial role. In the following text, our company's chief engineer will provide you with a detailed discussion on how to scientifically determine the parameters of the reactor in order to achieve reliable protection for the capacitor and ensure that the compensation capacity remains constant.

Understand the Core Function of the Detuning Reactor

The detuning reactor and capacitor are connected in series to form a tuning circuit. Its main function is to change the impedance characteristics of the circuit. Under the base frequency condition, the reactor presents inductive reactance, which will cause the terminal voltage of the capacitor to slightly decrease, thereby affecting its output capacity. At the harmonic frequency, the high impedance characteristic formed by the reactor and the capacitors can effectively suppress the harmonic current and prevent the capacitors from being damaged due to overcurrent. This balance point between protection and capacity is precisely set by the reactance rate of the reactor. The reactance ratio is the ratio of the inductive reactance of the reactor at the fundamental frequency to the capacitive reactance of the capacitors. This key parameter directly determines the tuning frequency and compensation effect of the entire set of equipment.

Grasp the Scientific Principles of Reactance Rate Selection

Selecting the appropriate reactance rate is another crucial factor for achieving the capacity balance of the capacitor protection and compensation cabinet. Common reactance rates include 6% and 7%, etc. Each reactance rate corresponds to a different tuning frequency point. Taking the reactor with a reactance rate of 6% as an example, its tuning frequency is approximately 189 hertz, mainly targeting the formation of high impedance for the fifth harmonic. When determining the reactance rate of the reactor, power system managers must first conduct detailed grid harmonic tests to identify the dominant harmonic frequency and content, as precise harmonic measurement is the basis for scientific reactor selection. If the fifth harmonic dominates in the power system, then choosing a reactor with a 6% reactance rate is the most appropriate. If the third harmonic is more prominent in the power system, a reactor with a higher reactance rate than 6% should be selected. It is particularly important to note that although an increase in reactance rate can provide better harmonic protection, it will also further reduce the voltage at the capacitor terminals, affecting the rated capacity output of the capacitor.

Implement the Matching Correction of Capacitor Capacity

After determining the use of a specific reactance rate for the reactor, the power system manager must make corresponding corrections to the capacity of the capacitor. Due to the voltage division effect of the reactor, the actual voltage applied across the capacitor terminals is lower than the grid voltage, which directly leads to a reduction in the reactive capacity output by the capacitor. To ensure that the compensation system still achieves the expected compensation effect, this capacity attenuation mentioned above needs to be taken into account in the design stage. The common practice is to appropriately increase the rated voltage level of the capacitor or increase its nominal capacity. Through this capacity matching correction, even when the reactor is installed, the system's demand for reactive compensation capacity can still be met. This forward-looking design thinking can effectively resolve the contradiction between protection and capacity, achieving the optimal balance between protection and capacity.

The Solutions and Professional Commitment of Geyue Electric

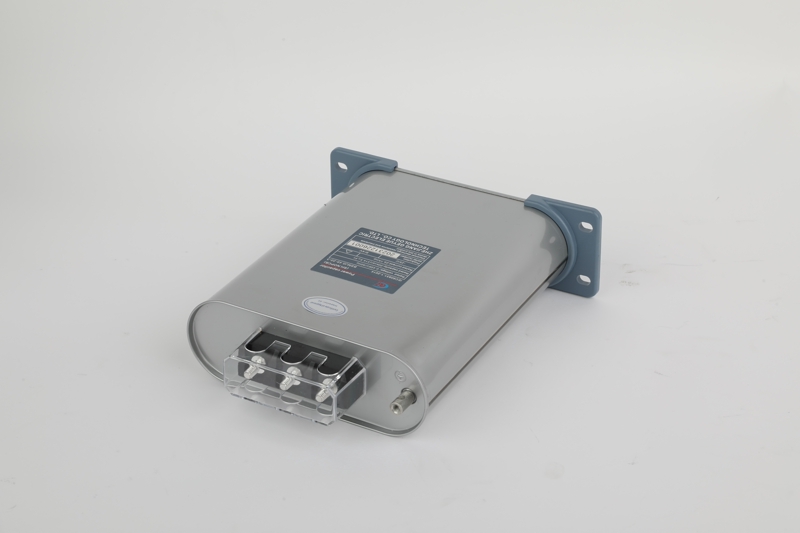

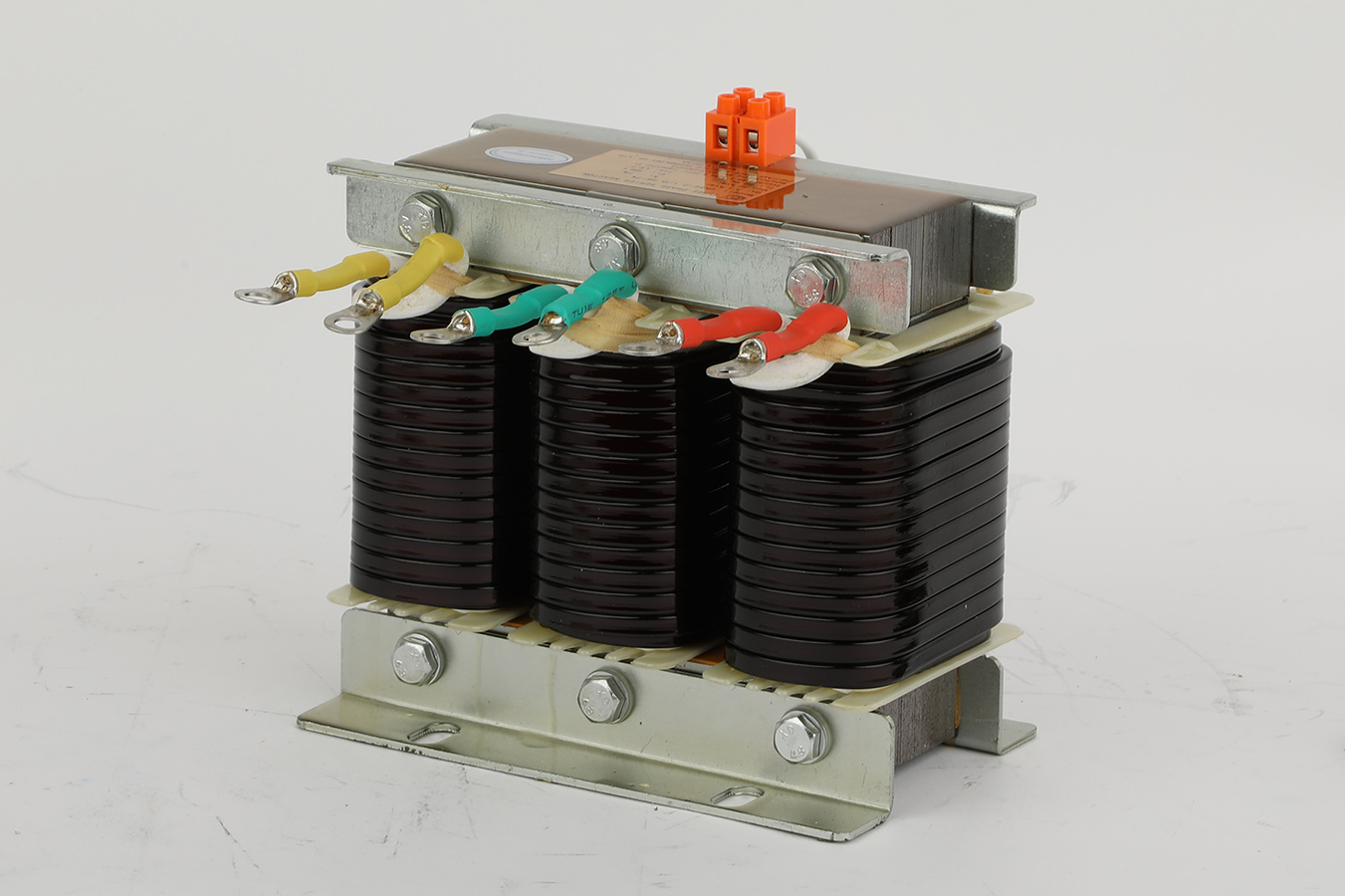

As a manufacturer with a long history in the field of low-voltage reactive power compensation, Geyue Electric has proposed our powerful solution to address the industry's recognized challenge of balancing capacitor reliability and compensation effectiveness. Our CKSG series of series reactors feature high-quality imported cold-rolled oriented silicon steel sheets as the core material, enabling the reactors to exhibit excellent characteristics of low loss and low temperature rise throughout the compensation process. The CKSG series of series reactors were developed by our engineering team through repeated precise calculations and continuous upgrades and optimizations, effectively suppressing specific sub-harmonics and minimizing the impact on the compensation capacity. Geyue Electric guarantees that our scientific parameter selection and reasonable capacity matching can help power system managers achieve reliable protection of capacitors without sacrificing the compensation effect. If you are confused about how to correctly select the size of the detuning reactor to ensure the protection of capacitors without compromising the compensation capacity, please send your inquiries to info@gyele.com.cn. Geyue Electric is willing to collaborate with you to solve harmonic problems and improve the operation quality of your power system.

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?