How does the Maturity of Made-in-China IGBT Modules Reduce the Manufacturing Cost of Static Var Generator(SVG)?

Static reactive power generators (SVG), as the core equipment for dynamic reactive power compensation in modern power systems, have long been constrained by the import dependence of key power devices such as insulated gate bipolar transistors (IGBTs) in terms of cost. In the past, international giants such as Siemens, Infineon and Mitsubishi monopolized the IGBT market, resulting in the high manufacturing cost of SVG. However, as Chinese manufacturers continue to improve and mature in IGBT module technology, the overall cost of SVG is experiencing a structural decline. In this article, the chief electrical engineer of Ge Yue Electric will lead you to conduct an in-depth analysis of how domestic IGBTs can promote cost reduction in SVG from three major dimensions: technology, supply chain, and customized services.

Technological Breakthrough: Made-in-China IGBTs is on par with International Standards, with Significant Advantages in Delivery Time and Cost.

In the early days, the technical bottlenecks of IGBTs made in China were in terms of voltage levels and reliability, which were specifically manifested as follows: Early IGBTs made in China were long confined to the low-voltage field (below 1200V), while SVGS required high-voltage modules ranging from 1700V to 3300V. After the painstaking technological research and development by Chinese IGBT manufacturers, the voltage level and reliability of IGBTs made in China have been greatly improved: The 3300V/1500A IGBT modules made in China have been batch-applied in wind power SVG. The 1700V automotive-grade IGBTs made in China have successfully passed the EC-Q101 certification, with a lifespan of up to 100,000 hours. The Chinese-made Hybrid IGBTs combining silicon-based and SiC reduce switching losses by 30%. The cost and delivery time of IGBTs manufactured in China can be reduced to half of those of imported IGBTs, and the effect of cost reduction and benefit gain is obvious. According to statistics, after SVG manufacturers replace imported IGBTs with those made in China, the BOM cost of a single SVG can be reduced by at least 20%.

Supply Chain Autonomy: Avoiding Risks and Ensuring Stable Delivery

If Chinese SVG manufacturers overly rely on imported IGBT supplies, they will inevitably have to bear many risks caused by non-human uncertainties. For instance, due to the influence of geopolitics, Infineon's delayed deliveries to China in 2022 led to the suspension of production for several SVG enterprises. For instance, due to the global chip shortage, the price of imported IGBTs soared by more than 1.5 times in 2023. Choosing IGBTs made in China to replace imported ones can completely avoid these unnecessary risks mentioned above. The localized production of IGBTs enables Chinese SVG manufacturers to independently control the supply chain, ensuring the stability of IGBT delivery. According to reliable records, the average annual production capacity of each IGBT factory in China can reach up to 300,000 pieces, which is sufficient to ensure a stable supply to downstream industries. Domestic IGBT factories have achieved vertical integration of the supply chain, with full autonomy in the entire process from raw materials to terminal products, and from chip design to module packaging, which has shortened the delivery cycle to the greatest extent. To strongly support the IDM model and promote full industrial chain autonomy, the Chinese government's "02 Special Project" has significantly lowered the research and development threshold for domestic IGBTs through financial support such as subsidizing the cost of domestic IGBT wafer fabrication, industrial chain integration, and policy guidance, accelerating the process of domestic substitution and enabling Chinese enterprises to gradually break overseas monopolies in fields such as new energy vehicles, photovoltaics, and industrial control. As domestic IGBT manufacturers gradually break the overseas monopoly, domestic SVG enterprises naturally embrace domestic IGBT manufacturers. It is understood that in 2023, the proportion of domestic IGBT purchases by domestic SVG enterprises rose from 15% to 45%, and it is expected to exceed 70% by 2025.

Customized Collaboration: Joint Optimization of Made-in-China IGBTs and Made-in-China SVGs

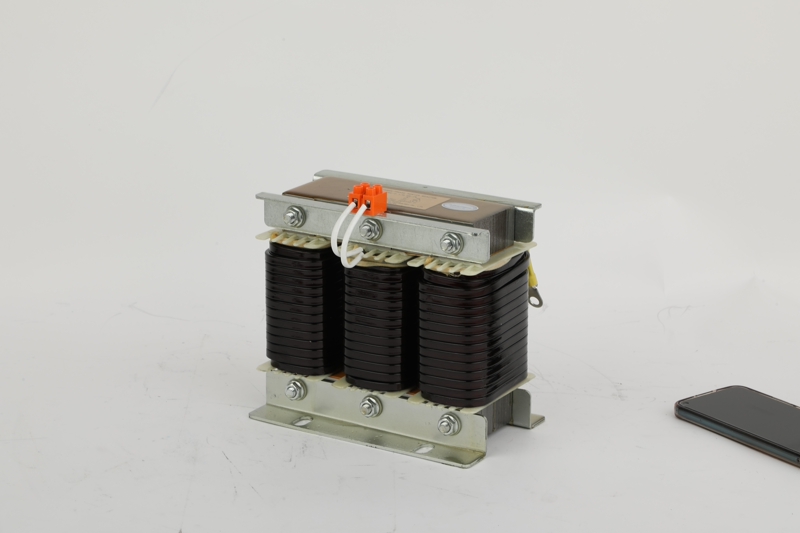

Imported IGBTs adopt standardized designs and sometimes are difficult to meet the high-frequency switching requirements of SVGS made in China. The IGBTs made in China usually adopt the "SVG dedicated module" design and the direct water cooling design on the copper substrate, featuring the function of low conduction loss optimization and the advantage of integrated heat dissipation. Chinese SVG manufacturers can collaborate with Chinese IGBT manufacturers to jointly customize system-level cost reduction solutions. Through topology simplification, the IGBTs made in China can support higher switching frequencies, reduce the usage of LC filters。 Through intelligent driving, the IGBTs made in China are equipped with built-in domestic driver chips, eliminating the need for external circuits. By leveraging this customized collaboration, SVG manufacturers can reduce the overall machine size by at least a quarter and minimize the heat dissipation cost.

In conclusion, the maturity of IGBTs made in China not only reduces the manufacturing cost of SVGS but also promotes the upgrading of Chinese enterprises' say in the global power electronics market. In the future, with automotive-grade IGBT technology feeding back to industrial applications and the integrated innovation of SiC and IGBT, domestic SVGS are expected to comprehensively surpass international competitors in terms of efficiency and reliability, becoming a typical representative of "new quality productivity". If you have any interest in the SVGs, please come to https://www.geyuecapacitor.com/, and contact Geyue Electric via info@gyele.com.cn.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?