The Core Value of Compound Switches in Compensation Systems

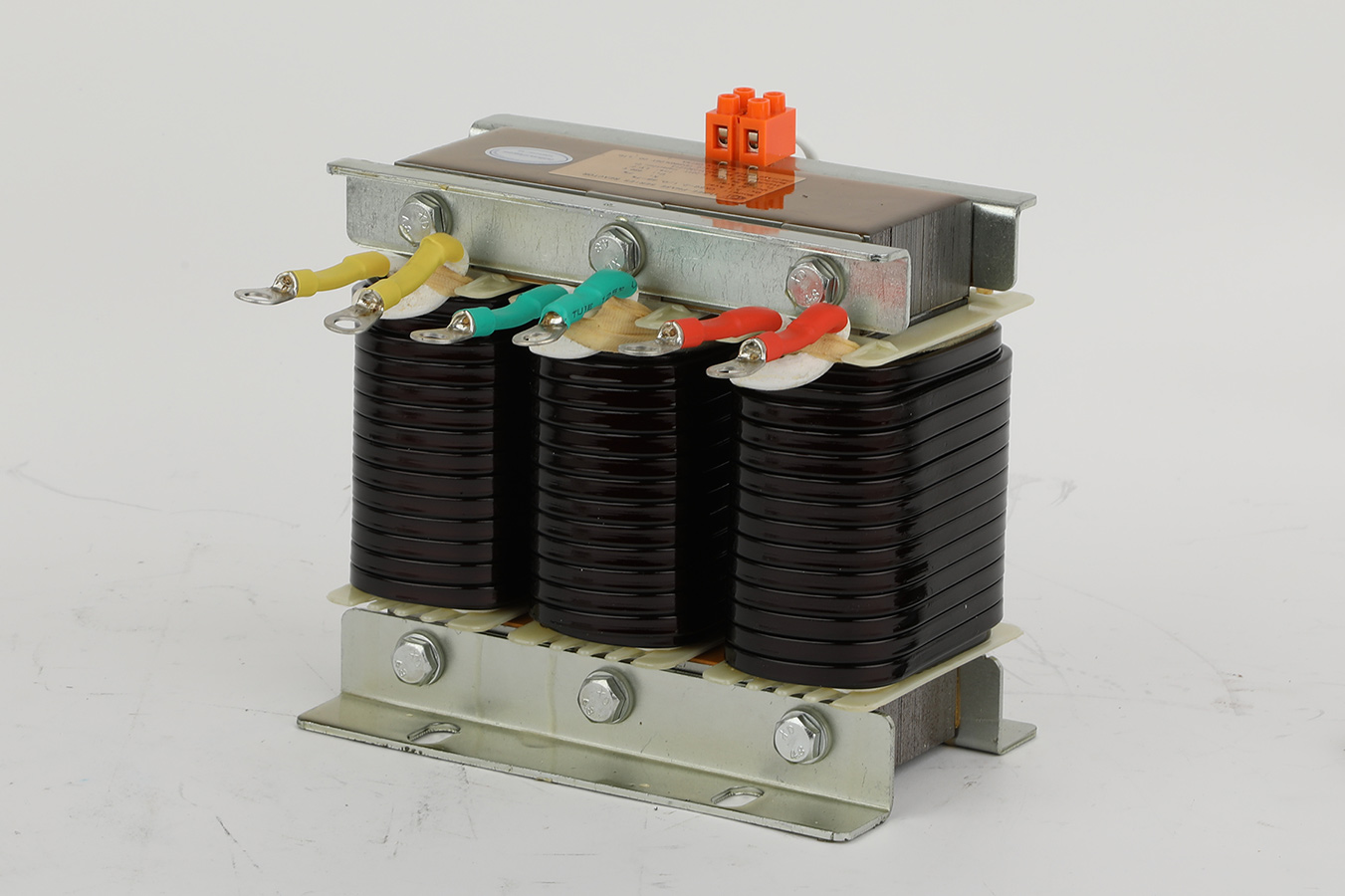

Traditional compensation devices face two major problems: dangerous sparks are generated when mechanical switches are disconnected, and tens of thousands of dollars are required to replace parts and shut down for maintenance each year. Three Phase Compound Switch precisely controls the on-off timing through electronic switches to eliminate the risk of sparks; the mechanical parts only conduct normal working current, and the life span will be increased by more than 20 times, and there is basically no need to replace parts; the 20ms extremely fast response stabilizes voltage fluctuations and avoids electricity fines. This technology transforms the power compensation system from a high-frequency maintenance device to a maintenance-free and reliable component, achieving a double breakthrough in intrinsic safety and economic operation.

Essential improvement in safety performance

When traditional AC contactors disconnect the current, dangerous arcs lasting 15ms to 20ms are generated, which is the main cause of fire and explosion in compensation cabinets. The composite switch uses semiconductor devices to accurately conduct when the grid voltage passes through zero, and the error of the action time is controlled within 50 microseconds; the mechanical contacts only bear steady-state current transmission, completely eliminating arcing conditions. This technology compresses the arc duration to less than 3ms, which is only one-seventh of the value specified by the national standard, and the measured arc energy attenuation is 94%. The system has passed the highest national explosion-proof safety certification, and the operating temperature is always below 1200 degrees Celsius. The fire extinguishing device has been removed at the industrial site to fully verify the safety and reliability.

Analysis of full-cycle economic benefits

The innovative design of the Three Phase Compound Switch divides the current into two processing paths: semiconductor devices are used to accurately control the instantaneous impact current of on and off, which can withstand 10 times the instantaneous load. The mechanical contacts only transmit steady-state current, so ablation loss is eliminated. The contact life can exceed 2 million operations, completely ending the need for spare parts procurement. The standby power consumption is reduced to 0.3W, while the traditional solution is 8W. Due to the pulsed working characteristics of semiconductors, the annual electricity bill savings exceed 10,000 yuan. The zero-crossing conduction technology can suppress the capacitor closing inrush current to within 2 times the rated current, while the traditional solution is 15-20 times, reducing the capacitor temperature rise by 18K, slowing the dielectric aging rate by 65%, and extending the life to more than ten years.

Analysis of performance adaptability to extreme environments

The Three Phase Compound Switch achieves stable operation in all scenarios through innovative materials and structural design. The high-frequency heat dissipation ceramic substrate combined with microchannel cooling technology can ensure that the equipment can continue to work in a high temperature environment of 125 degrees Celsius without derating. Military-grade potting materials constitute a fully sealed protection system, which has successfully passed a thousand-hour anti-corrosion verification and completely isolates it from moisture, salt spray and conductive dust. The seismic-resistant structure adopts elastic fixing technology and can withstand continuous mechanical vibration of 10G acceleration, which is equivalent to a magnitude 8 earthquake on the Richter scale. The performance fluctuation of core components is less than 0.5 parts per million under a wide temperature range of -40 degrees Celsius to 125 degrees Celsius, which can ensure ten years of long-term operation in harsh scenarios such as extreme cold in mines and high temperatures in metallurgy.

Composite switch harmonic tolerance core technology

The Three Phase Compound Switch ensures stable operation in complex power grid environments through a triple protection mechanism:

First, the built-in spectrum scanning system monitors the 0.5-3 kHz frequency band in real time, automatically locks and avoids the 5th, 7th, and 11th key harmonic resonance points;

Second, the anti-harmonic module with a 7% standard reactance rate can effectively suppress more than 85% of the characteristic harmonic amplitude;

Third, the 20 kV protection array composed of transient suppression diodes and varistors fully absorbs the transient overvoltage caused by switch operations.

This technical system enables the equipment to maintain a service life of more than ten years under harsh working conditions with a total harmonic distortion rate of 25%, providing reliable protection for high-interference scenarios such as inverter clusters and medium-frequency furnaces.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?