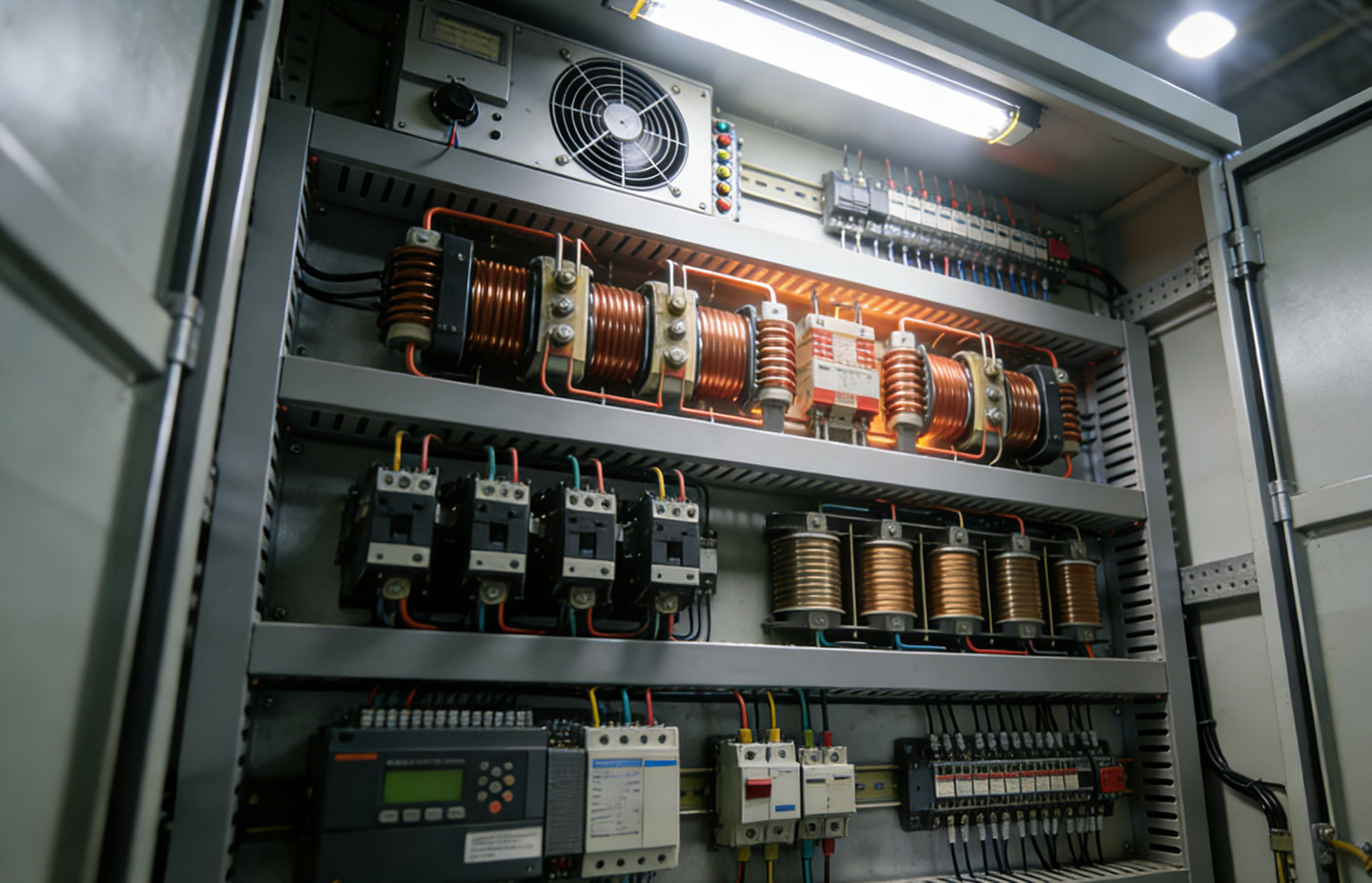

Contactor's Electricity Black Hole: Why 98% of Electricity Is Not Actually Consumed?

In the field of industrial controllers, traditional electromagnetic contactors have a structural energy consumption defect. In order to maintain the contact closure, its coil needs to continuously consume 5-10W of power, resulting in more than 95% of the electrical energy being converted into invalid heat. Geyue Electric's CJ19 Series AC Contactor for Switching Power Capacitor achieves an essential change in the energy conversion path by physically reconstructing the energy conversion path through a magnetic holding structure. Its core lies in the innovation of the traditional one-way dissipation chain of current-magnetic energy-mechanical energy into a closed-loop system of electrical energy → magnetic mechanical energy storage → zero power consumption retention → magnetic energy recycling. The contactor consumes electrical energy only within 0.5 seconds of power-on to generate electromagnetic force, drive the moving iron core to attract and magnetize the permanent magnet. The magnetized NdFeB permanent magnet forms a closed magnetic circuit, converting electromagnetic energy into a stable mechanical locking state. Once the attraction is completed, the system immediately cuts off the power supply and relies on the magnetic force of the permanent magnet itself to continuously maintain the closed state, achieving staged zero current and zero power consumption operation. This design transforms the traditional contactor's electromagnetic holding mode, which requires continuous power supply, into a physical magnetic holding mode, fundamentally eliminating standby energy consumption.

Explanation of the energy efficiency defects of traditional contactors

The working principle of traditional contactors has natural energy efficiency defects. When the coil is energized, electromagnetic force is generated to attract the moving iron core. At this time, current must be continuously supplied to maintain magnetic flux to keep the contacts closed. Taking the AC220V/50Hz contactor as an example, the power consumption at the start-up moment is about 30W, and the power consumption in the holding stage is still about 8W. This continuous power consumption state accounts for more than 95% of the total operating time of the equipment, and most of the electrical energy is converted into invalid heat energy, causing the temperature rise in the coil area to exceed 75°C. If it is operated for a long time, it will not only cause a waste of electricity, but also require additional heat dissipation costs for the distribution cabinet, forming a double burden of power loss and thermal management.

CJ19 Series AC Contactor energy-saving working mechanism

The CJ19 series AC contactor achieves high efficiency and energy saving through three stages. First, in the pull-in action stage, the pulse coil is energized for 0.5 seconds to generate 30 watts of instantaneous power. The electromagnetic force drives the iron core to close while magnetizing the permanent magnet. Then it enters the holding state stage. The magnetized permanent magnet and the iron core form a physical self-locking structure, completely cutting off the power supply of the coil to achieve zero power consumption and continuous closure. Finally, in the disconnection action stage, a 0.3 second reverse pulse current is passed to release the magnetic retention, and the mechanical energy pre-stored in the spring pushes the iron core to separate, reducing the power consumption of the disconnection. The energy management in these three stages can make the equipment consume no energy for 95% of the operating time, and reduce the power consumption of the disconnection operation by recovering mechanical energy.

CJ19 Series AC Contactor energy saving and economic comparison table

| Performance Dimensions | Traditional contactor | CJ19 series AC contactor | Energy efficiency improvement | Annual economic benefits per unit (based on $0.12 /kWh) |

| Continuous power consumption | 8W | 0W | 100% | Save 64 KWH → $7.3 |

| Annual total power consumption | 86 KWH | ≤5KWH | 94%↓ | Total electricity bill savings: $9.52 |

| Arc energy loss | 100% energy dissipation | 38% energy dissipation | 62%↓ | Reduce cooling costs by $2.2 |

| Coil temperature rise | 75℃ Annual cooling cost $1.8 | 35℃ Annual cooling cost $0.53 | 70%↓ | Save air conditioning fee $1.24 |

| Contact life | Replace once every 3 years | Replace once every 8 years | Maintenance fee↓67% | Save spare parts + labor $4.7/year |

| 8-year comprehensive income | - | - | Economic leap | Total savings $101 |

Summary: Really save every kilowatt-hour of electricity for you

With the mission of reducing the cost of industrial electricity, Geyue Electric created the CJ19 series AC contactor. It can maintain zero power consumption in stages, avoid standby waste, and save 64KWH per year. The coil temperature drops by 40℃ to reduce the heat dissipation burden and reduce maintenance expenses. From production lines to substations, Geyue Electric uses technological innovation to accurately deliver power-saving benefits to your cost report. Choosing the CJ19 contactor means saving electricity bills in a real way - every kilowatt-hour saved can be seen and calculated, and it will become your profit over time. Visit https://www.geyuecapacitor.com/ to get exclusive cost-saving plans.

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?