The Layout Art of Components in the Low-Voltage Reactive Power Compensation Cabinet: How do Heat Dissipation, Wiring, and Safety Spacing Affect the Long-Term Stability of the System?

Introduction: The layout inside the cabinet is not only aesthetically pleasing but also the cornerstone of stability

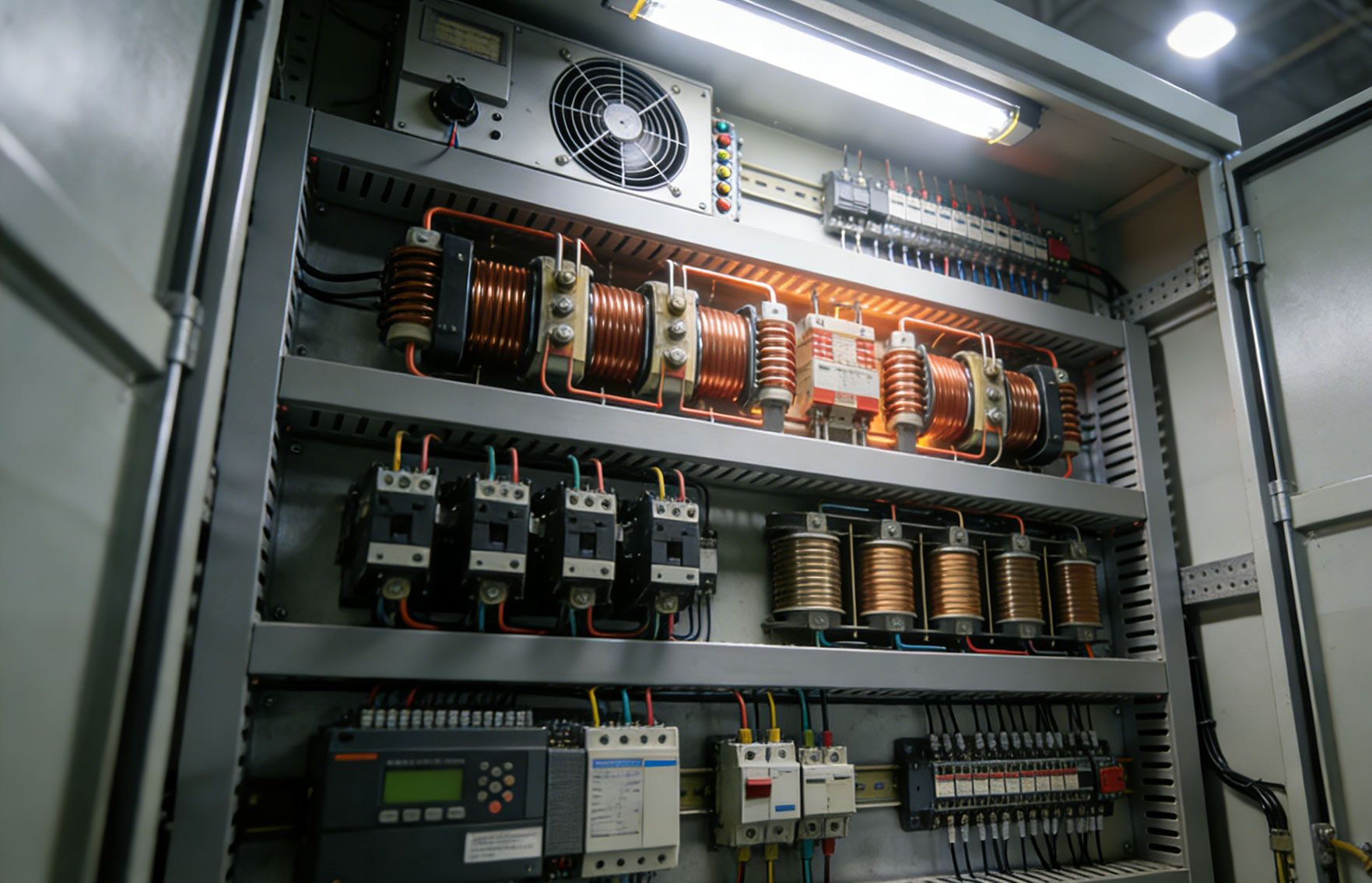

The compensation cabinet is the core component of the low-voltage reactive power compensation system. The layout of its internal components directly determines the operational efficiency and service life of the entire device. As a Chinese manufacturer of low-voltage reactive power compensation equipment with a long history in the power industry, Geyue Electric fully understands that an excellent compensation solution not only requires high-quality components, but also relies on a scientifically reasonable internal design of the cabinet. The interrelationships among heat dissipation, wiring, and safety spacing form the solid pillars for the long-term stable operation of the compensation cabinet.

Heat Dissipation: Temperature control determines the lifespan of components

During the operation of the compensation cabinet, internal components such as capacitors, reactors, compound switches, contactors and power factor controllers will generate a certain amount of heat. If this heat cannot be dissipated in time, it will cause the temperature of the components to continuously rise, accelerate the aging of the insulation materials, reduce the capacity of the capacitors, and even lead to thermal breakdown. Geyue Electric, when designing the cabinet, based on the vertical layered heat dissipation layout, placed the components with higher heat generation at the upper part of the cabinet. Moreover, our technical team utilized the principle that hot air rises naturally, combined with the top fan for forced ventilation, to form a smooth airflow from bottom to top. At the same time, we reserved sufficient heat dissipation channels between the capacitors to avoid heat accumulation between the capacitors, so that even in a high-temperature environment in summer, the cabinet temperature can be controlled within a safe range, ensuring that the components always operate in an ideal state, thereby extending the overall system lifespan.

Wiring: A precise network reduces interference and voltage drop

The wiring inside the compensation cabinet may seem simple, but it actually contains profound knowledge of electrical engineering. The disorganized wiring not only affects the appearance but also introduces electromagnetic interference, increases line voltage drop, and even causes local discharge. Geyue Electric adopts the wiring principle of "separating strong and weak electricity and dividing high and low frequency areas". The control lines and power lines are routed separately to avoid signal interference; the main circuit uses copper bars for connection to reduce contact resistance and heat generation; the sampling circuit uses twisted shielded cables to ensure measurement accuracy. All cables are fixed in a standardized manner through conduits to avoid loosening due to vibration. Our company's carefully designed wiring network ensures smoother current transmission and more accurate signal collection, thereby providing a detailed guarantee for the reliable response and long-term stability of the low-voltage reactive power compensation system.

Safety Spacing: Insulation and maintenance form a dual guarantee

Although the voltage level inside the compensation cabinet belongs to the low-voltage category, sufficient safety distances still need to be maintained between components and between components and the cabinet body. This is not only to meet the insulation requirements and prevent arcs and short circuits, but also to facilitate daily inspection and maintenance. Geyue Electric strictly follows international standards, national standards and industry norms. Therefore, during the design stage, we determined the optimal installation positions of each component through three-dimensional simulation methods. We reserved sufficient space between capacitors to facilitate heat dissipation and insulation; we also kept the live parts at a safe distance from the cabinet door to ensure the safety of operators; at the same time, we also reserved spacious operation surfaces for components that need frequent observation and maintenance.The reasonable layout of the safety spacing not only reduces the failure risk of the entire low-voltage reactive power compensation system, but also makes the later maintenance more convenient and efficient, and reduces the total operating cost of users.

Geyue Electric: We safeguard power system stability with meticulous craftsmanship

It is precisely because of the profound understanding and meticulous control of details such as heat dissipation, wiring, and safety spacing that Geyue Electric's low-voltage reactive power compensation cabinets can operate stably and continuously in various harsh industrial environments. Our manufacturing plant features fully automated production lines and standardized assembly processes. Every piece of equipment leaving the factory undergoes strict thermal balance tests, electrical performance tests, and insulation withstand voltage tests. We not only provide high-quality compensation cabinets but also can customize comprehensive reactive power compensation solutions including intelligent capacitors, reactors, and filtering modules based on the user's load characteristics, helping users effectively improve power factor, reduce line losses, and avoid penalty charges for power regulation fees. If you have any needs, please consult info@gyele.com.cn. Let Geyue Electric, with our exquisite layout art and reliable reactive power compensation solutions, safeguard the energy efficiency and stability of your power system.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.