From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

Preface

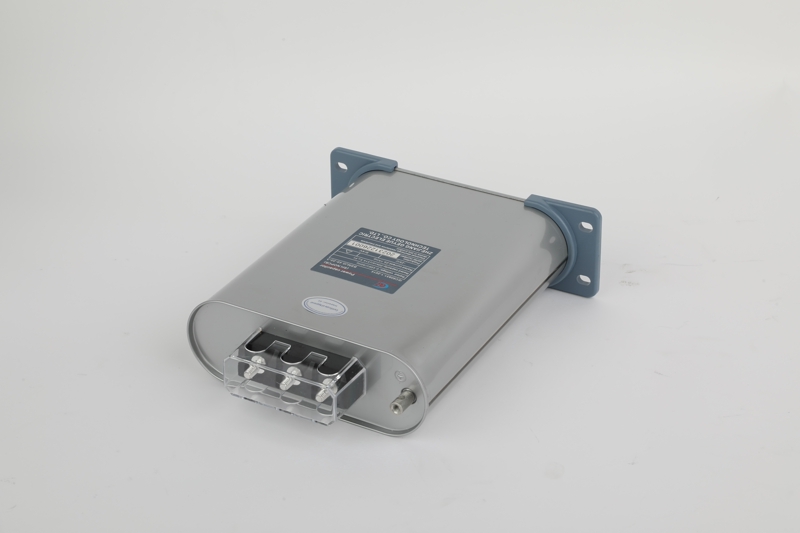

A customer initially ordered a JKW5C Automatic Power Factor Controller sample from us, hoping to test its performance. Their factory, which manufactures precision electronic components, is particularly concerned about power supply quality, fearing that unstable voltage would impact production. After we sent them the sample, their technical department spent two weeks testing it, focusing specifically on key indicators like response speed and switching accuracy. The feedback was positive, particularly regarding accurate power factor control, which reassured them.

Field Trials

After the sample passed the tests, the customer installed the device in their workshop's power distribution room for a hands-on test. The reactive power compensation controller operated continuously for three months, with us constantly monitoring the backend data. Unexpectedly, the results exceeded expectations, with the power factor increasing from 0.78 to 0.96 and a monthly electricity bill reduction of five percentage points. The customer's on-site manager commented that the production line had become much more stable during this period, giving them peace of mind.

How We Ensure Quality

Frankly, the biggest concern when working with power equipment is unstable quality. Our factory conducts seven inspection steps for each JKW5C, covering everything from high-temperature aging to voltage fluctuations. Inspectors monitor every workstation on the assembly line, ensuring that any component failures can be traced directly back to the supplier. While this approach is labor-intensive, it provides peace of mind for customers.

A large order arrived naturally.

After seeing the actual operating data, the customer immediately placed an order for 1,000 units. Hearing that they would be replacing our JKW5C Automatic Power Factor Controller in over a dozen of their factories nationwide, this order immediately broke the company's sales record. The purchasing manager explained that they prioritized the equipment's stability, considering that the previous prototype had run flawlessly for three consecutive months.

Working overtime to ensure delivery.

Faced with such a large order, the production department scrambled to adjust their schedules. Previously, one line could produce 200 units per month, but now, operating three shifts, we can ramp up to 300. We also assigned personnel to monitor component supply on-site, fearing any potential glitches. Despite the tight deadlines, we maintained our testing standards and ensured that every unit still completed the seven steps before leaving the factory.

After-Sales Support

With such a large number of devices in operation, we've established a dedicated customer service team. Any customer issues can be quickly addressed remotely with a single call, and in special cases, we can arrive on-site within two hours. We also schedule quarterly inspections to regularly check the equipment's operating status.

Great Potential for Future Collaboration

This collaboration has truly demonstrated our capabilities to the customer, and their technical director recently arranged to discuss future upgrade plans. We are currently developing a new generation of JKW5C Automatic Power Factor Controller, with plans to add smart meter integration. We plan to have them test the next sample as soon as it becomes available. A good product truly requires customer collaboration.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.

- How Can We Effectively Educate the Market and Enable Customers to Recognize the Long-Term Value Brought by "High-Quality Compensation"?