Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

As a key interface for power transmission, the “current-carrying capacity” of the connection terminals of self-healing shunt capacitors directly determines the continuous operation capability of the capacitors. During the product development process of Geyue Electric, the performance of the capacitor terminals is regarded as the core design criterion for the capacitors. This is because our company is well aware that reliable electrical connection is the decisive foundation for the long-term stable operation of the capacitors. High-quality terminals can ensure that the capacitors maintain a stable temperature rise level during full-load operation, and this characteristic is of crucial significance for extending the service life of the capacitors.

The Technical Connotation of "Current-Carrying Capacity"

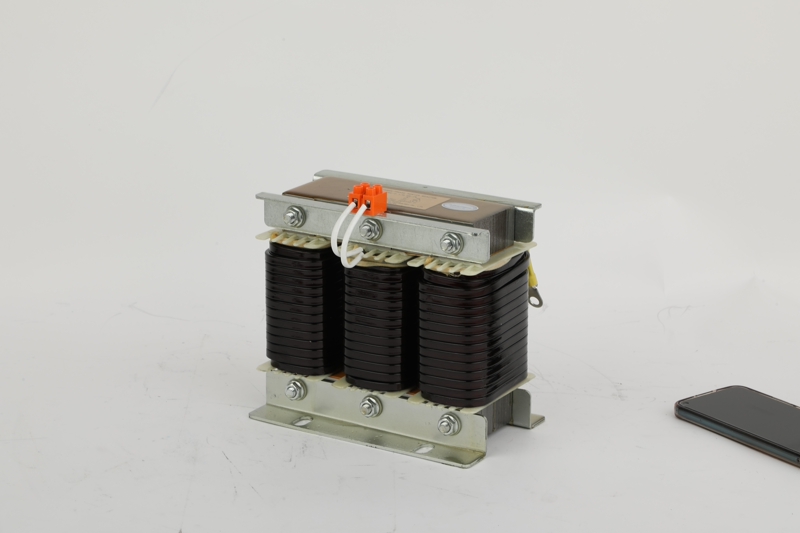

The “current-carrying capacity” of the capacitor terminals refers to the maximum current value that the connection terminals can safely withstand during the long-term operation of the capacitor. The engineering team of Geyue Electric has determined the rated current-carrying parameters for each model product through precise calculations. These parameters fully take into account the possible harmonic current influence in the power grid. The BSMJ series self-healing shunt capacitors we developed adopt a firm structural design with thickened copper terminals, ensuring that the terminals can maintain a low contact resistance throughout the actual operation of the capacitors.

The Prevention Mechanism of Overheating Risk

When the “current-carrying capacity” of the capacitor terminals is insufficient, excessive heat accumulation occurs at the connection points, causing the terminals to overheat. When the metal of the terminals (usually copper or aluminum) is continuously overheated, it reacts with oxygen in the air to form a layer of metal oxide film (copper reacts with oxygen to form copper oxide, and aluminum reacts with oxygen to form aluminum oxide). This oxide film has a much lower conductivity than the metal itself because it is like an insulating, rough "rust" covering the contact surface of the conductor. Due to the increased resistance, the heat generation increases, and the temperature of the terminals becomes higher than before, thus forming a vicious cycle, accelerating the oxidation reaction and generating a thicker and more resistive oxide layer. Geyue Electric conducts strict temperature rise tests on each terminal before the BSMJ series self-healing shunt capacitors are manufactured. Our test data indicates that qualified terminals' temperature rise must be controlled within the range specified by the national standard, effectively preventing various faults caused by overheating.

Special Considerations for Harmonic Environments

The harmonic currents in modern industrial power grids significantly increase the actual working current of capacitors. The terminal “current-carrying capacity” of the Geyue Electric's BSMJ series self-healing shunt capacitors is strictly designed in accordance with redundant specifications that exceed industry standards. The rated value of our terminal “current-carrying capacity” not only meets the operation of the capacitors at the nominal current, but also reserves sufficient space to cope with additional pressures caused by harmonic currents, transient overloads, and long-term aging, fundamentally eliminating the risk of overheating of the capacitors due to terminal overload. Engineering practice has shown that this generous design concept can effectively handle a current harmonic distortion rate of up to 30%, making an allowance for the adaptability of the capacitors in complex power grid environments.

Guarantee Measures for Connection Reliability

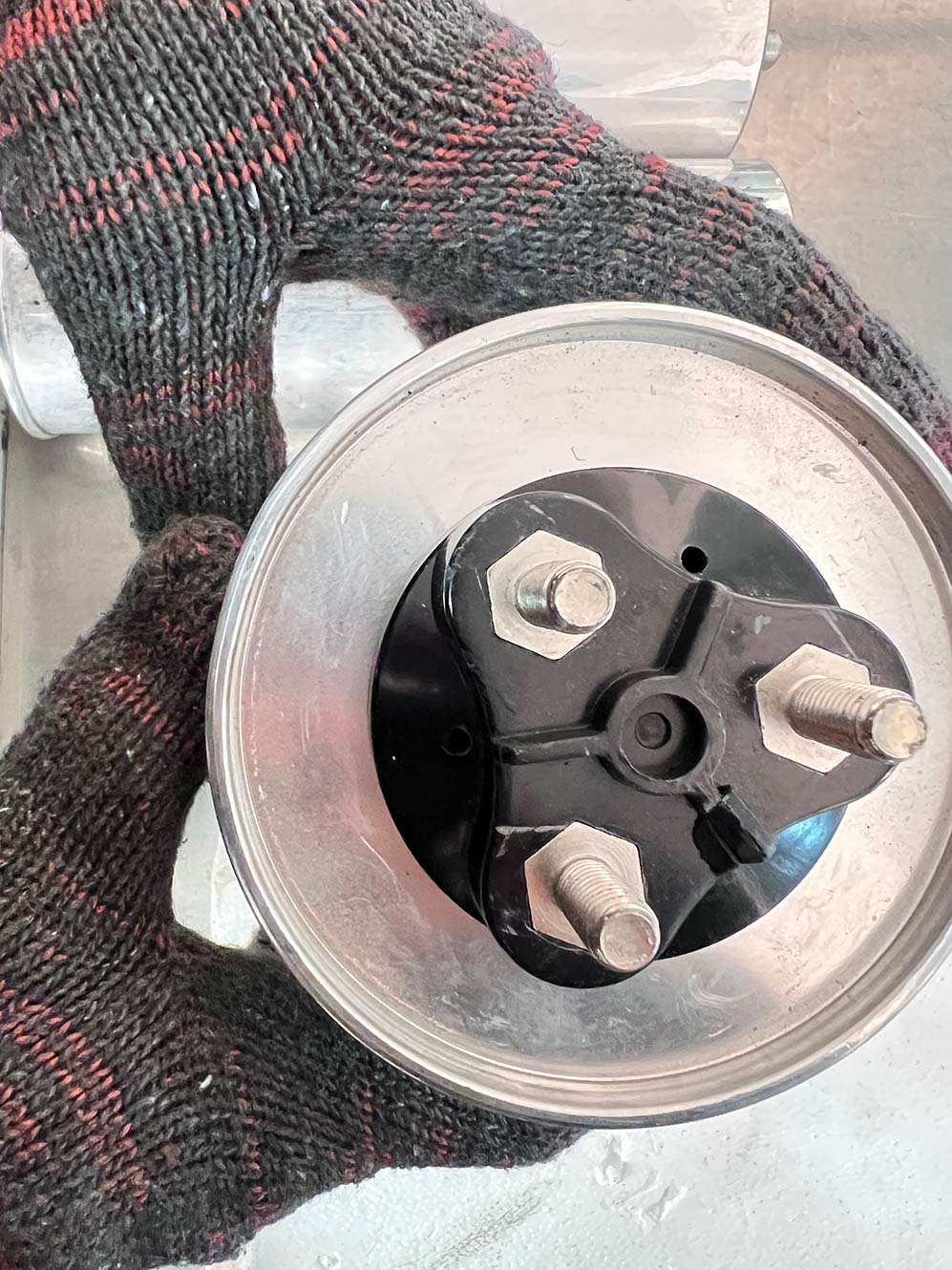

Insufficient “current-carrying capacity” of capacitor terminals often leads to derivative problems such as loosening during electrical connections. The BSMJ series self-healing shunt capacitors of Geyue Electric utilize special end-face processing technique during the manufacturing process. This process not only ensures that the terminals always maintain good conductivity but also provides sufficient contact pressure for the terminals. Our production line employs a torque-controlled tool for terminal assembly, making a certain that each terminal can reach the optimal connection state, significantly enhancing the connection reliability of the capacitors.

The Scientific Basis for Material Selection

Geyue Electric always carefully selects copper alloys with high conductivity as the base material for the terminals of capacitors. This material has excellent creep resistance and strong mechanical strength. Our material laboratory regularly conducts component analysis on the copper materials provided by suppliers, with the aim of ensuring the complete compliance of raw materials with technical specifications from the source. In addition, our exquisite tin-plating process makes the copper terminals have good corrosion resistance and can remain intact for a long time to serve the low-voltage reactive power compensation system.

The Quality Practice of Geyue Electric

Geyue Electric has established a comprehensive terminal quality traceability system, which covers the entire process from raw material entry to finished product exit. Our BSMJ series and BSMJ(Y) series self-healing shunt capacitors have all passed strict “current-carrying capacity” tests, and all the test data are recorded in the product quality files. Geyue Electric sincerely recommends to users that when selecting capacitors, you must pay attention to the “current-carrying capacity” parameters of the terminals, as this data often determines the actual service life of the capacitor. If you have more concerns about “current-carrying capacity” of capacitors, don’t hesitate to drop an email to info@gyele.com.

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.

- How Can We Effectively Educate the Market and Enable Customers to Recognize the Long-Term Value Brought by "High-Quality Compensation"?