In-Depth Analysis of the Core Advantages of Three-Phase Compensation Intelligent Low Voltage Power Capacitor Device

The traditional split compensation solution of capacitor + contactor + controller has drawbacks in daily factory use: frequent ablation of contacts will consume tens of thousands of spare parts per month, delayed mechanical response will lead to continuous power supply fines, and failures in the collaboration of multiple components require real-time maintenance by electricians. The Three-Phase Compensation Intelligent Low Voltage Power Capacitor device uses an integrated sealed structure to replace mechanical contacts with solid-state semiconductor devices, fundamentally eliminating the risk of contact ablation. It uses a high-speed FPGA chip for reactive power calculation, achieving a dynamic response of ≤20ms, and accurately stabilizing the power factor to avoid power supply fines. The modular plug-in design supports live replacement operations, and on-site transformation takes about 5 minutes, significantly reducing production line downtime losses.

Analysis of structural problems of traditional capacitor compensation system

The split reactive power compensation solution is composed of three independent devices: Power Capacitors, AC contactor and power factor controller. There are systematic technical shortcomings: the capacitor is subjected to the impact of 10-15 times the rated current for a long time, and the internal insulation medium deteriorates rapidly, resulting in an average annual failure rate of more than 23%, causing irreversible damage such as bulging and leakage; the mechanical contact of the contactor generates an arc lasting 15-20ms when disconnecting the capacitive load (exceeding the national standard safety limit), causing contact erosion and an annual loss cost of about $12,000; the controller sampling cycle lag (≥200ms) causes dynamic response hysteresis, and cannot track the impact load changes in real time, resulting in a fine of about $1,100 per month due to power factor. System maintenance requires coordination of capacitor, switch and control suppliers for joint troubleshooting, which takes 216 man-hours per year, and component interface compatibility issues occur frequently, causing an average annual loss of $47,000 in unexpected downtime.

Integrated technical advantages of the Three-Phase Compensation Intelligent Low Voltage Power Capacitor device

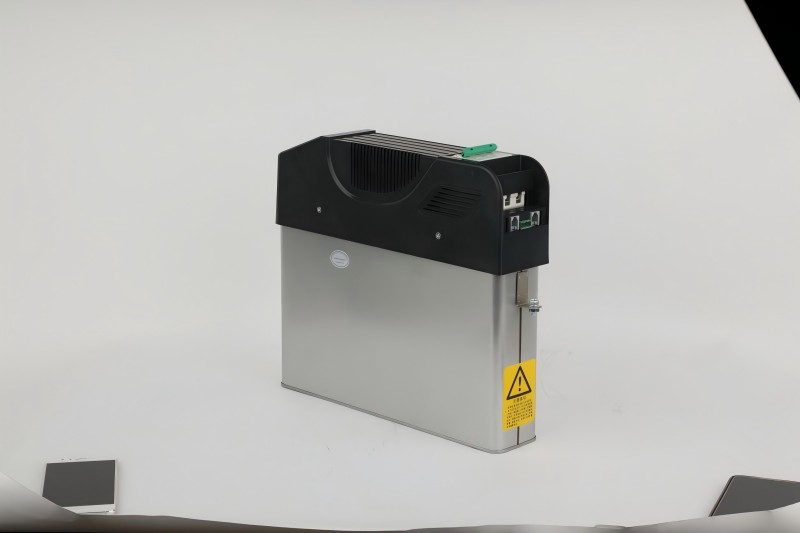

Geyue Electric's GY-ZMG series Three-Phase Compensation Intelligent Low Voltage Power Capacitor device adopts an integrated packaging design, integrating capacitors, composite switches and controllers in an IP55 protection grade housing. The core semiconductor arc extinguishing technology compresses the arc duration to 3 milliseconds (only 15% of the national standard allowable value of 20 milliseconds), completely eliminating contact ablation. The device has a 20-millisecond dynamic response capability to ensure that the power factor is stably maintained above 0.98. The three-proof potting process effectively blocks dust and moisture erosion and achieves 800 consecutive days of zero maintenance operation. On-site installation only requires connecting four sets of bolts to access the busbar system. The entire transformation process is completed within five minutes, and live operation is supported without affecting production.

Maintenance cost comparison table

| Expense Type | Traditional capacitor compensation solution | Intelligent compensation device | Savings |

| Spare parts procurement expenses | $42, 262 | $0 | $42, 262 |

| Downtime loss costs | $144, 196 | $0 | $144, 196 |

| Total cost over three years | $225, 000 | $14, 431 | $186, 458 |

Improved operation and maintenance efficiency brought by intelligent devices

The operation and maintenance of traditional reactive power compensation supporting systems have the inherent characteristics of high frequency, high consumables, and high risks. Industry data show that an average of 38 cabinet maintenance operations are performed per month, and an average of 6 pairs of protective gloves are consumed annually; sudden failures and emergency repairs frequently lead to production line shutdowns, and a single loss can reach 4,000 US dollars. After adopting The Three-Phase Compensation Intelligent Low Voltage Power Capacitor device, the operation and maintenance mode is transformed into a combination of quarterly dust removal and maintenance and real-time monitoring on mobile terminals; device abnormalities are remotely diagnosed and handled by the manufacturer's technical team. The operation and maintenance nodes are reduced by 87%, and the consumption of protective consumables is reduced to zero. The intelligent reactive power compensation device can self-monitor the status and issue an early warning before a failure occurs, so that 93% of maintenance work does not require manual on-site operation.

Analysis of direct economic value of Intelligent Low Voltage Power Capacitor device

The intelligent low-voltage reactive power compensation device converts the electricity penalty in the traditional scheme into an annual reward, with an income of approximately US$22,000. The 100% guarantee for continuous production equipment effectively increases production capacity by 3.2%. After optimizing the labor costs of the operation and maintenance team, US$26,000 in benefits are released each year. The total amount of the three comprehensive benefits reaches US$130,000. After the fund made a secondary investment to expand production capacity, it has been verified that it can drive profit growth of more than 200%.

Get a complete technical solution

If you want to know the detailed technical parameters, industry solutions and economic benefit calculation of Intelligent Low Voltage Power Capacitor devices, please visit Geyue Electric's official website https://www.geyuecapacitor.com/

The website provides product manual downloads, engineering case libraries and online consulting services. The professional team will provide you with customized energy-saving transformation solutions.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?