Why Has the Oil and Gas Industry Become a New Growth Point for Reactive Power Compensation?

With the transformation of the global energy structure and the acceleration of electrification, the oil and gas industry, as a representative of the traditional energy field, is facing severe challenges in improving energy efficiency and reducing carbon emissions. In this context, the application value of power quality management and reactive power compensation technology in the oil and gas industry is becoming increasingly prominent. In this article, the Chief Electrical Engineer of Geyue Electric will explore why the oil and gas industry has become a new growth point for reactive power compensation from the perspective of a low-voltage reactive power compensation equipment manufacturer. By analyzing the industry characteristics, technical requirements and market drivers of the oil and gas industry, the development potential of this emerging market will eventually be revealed.

Characteristics of power demand in the oil and gas industry

The power demand in the oil and gas industry has significant particularity, which puts forward unique requirements for reactive power compensation equipment. Firstly, the load characteristics of the industry are complex and changeable, including nonlinear loads such as high-power motors, variable frequency drives, and compressors. These devices will generate a large amount of harmonics and reactive power during operation, resulting in a decrease in the power factor of the power grid. Secondly, oil and gas production facilities are usually located in remote areas, with relatively weak power grid conditions and poor voltage stability, which require higher power quality. In addition, the production process of the oil and gas industry is characterized by high continuity and safety requirements. Any power outage or power quality problem may lead to production interruption, equipment damage, or even safety accidents, resulting in significant economic losses. Therefore, the industry's requirements for power supply reliability and power quality are much higher than those in the general industrial field. This special demand provides a broad application space for reactive power compensation equipment.

Current application status of reactive power compensation in the oil and gas industry

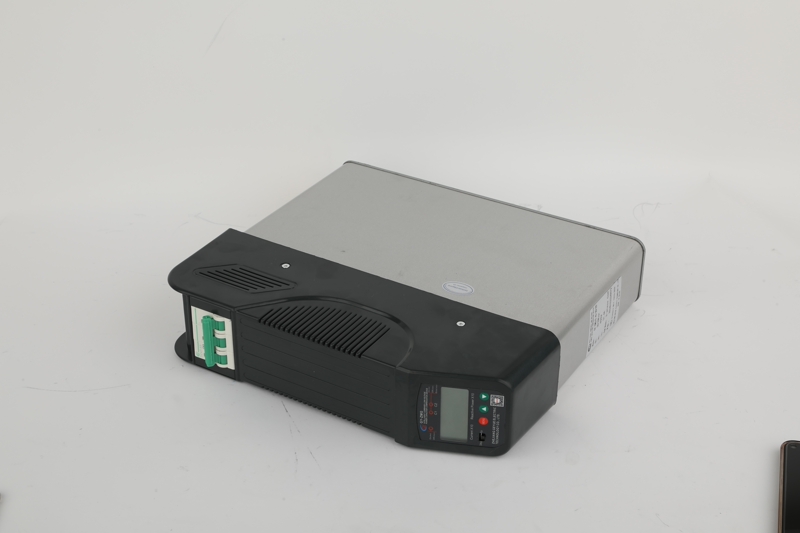

At present, the application of reactive power compensation technology in the oil and gas industry is mainly concentrated in the following key links. In the oil and gas field exploitation link, periodic loads such as beam pumping units require dynamic reactive power compensation devices to balance power fluctuations; in the long-distance pipeline link, large compressor stations require static reactive power generators (SVG) to improve the power factor; in the refining link, complex process production lines require comprehensive power quality management solutions. When demand exceeds supply, the limitations of the current application of reactive power compensation technology in the oil and gas industry are becoming increasingly clear. On the one hand, many old facilities still use traditional fixed capacitor bank compensation methods, which cannot adapt to the needs of rapid load changes; on the other hand, there is a relative lack of special reactive power compensation equipment designed for special environments in the oil and gas industry (such as explosion-proof, anti-corrosion, etc.). These unsatisfactory compensation results have discovered a blue ocean for reactive power compensation equipment manufacturers, providing opportunities for product upgrades and customized development in the field of reactive power compensation.

The driving factors to become a new growth point for reactive power compensation

The oil and gas industry has become a new growth point for reactive power compensation, mainly driven by three factors. Firstly, the electrification level of the industry continues to increase, and more and more traditional mechanical drive equipment is replaced by electric drive equipment, increasing the demand for power quality management. Secondly, increasingly stringent energy efficiency regulations and carbon emission standards around the world have forced oil and gas companies to seek various energy-saving technologies, and reactive power compensation is an effective means to improve energy efficiency. Thirdly, with the increasing application of renewable energy in the oil and gas field (such as oilfield photovoltaics, wind power, etc.), the power quality problems caused by the grid connection of distributed energy need to be solved by reactive power compensation technology. In addition, the trend of digitalization and intelligence has also driven the growth of demand for intelligent reactive power compensation equipment. These factors work together to make the demand for reactive power compensation equipment in the oil and gas industry show a rapid growth trend.

Development trends and market opportunities

Looking ahead, it is not difficult to find that the reactive power compensation technology in the oil and gas industry will show the following obvious development trends. Firstly, the intelligence of equipment will be improved, and remote monitoring and adaptive compensation technology based on the Internet of Things will become standard; secondly, integrated solutions are more popular, and the demand for comprehensive power quality devices that integrate reactive power compensation, harmonic control, voltage regulation and other functions will increase; thirdly, the development of special equipment for special environments will be accelerated, such as explosion-proof and corrosion-resistant reactive power compensation devices. For reactive power compensation equipment manufacturers, these trends bring significant market opportunities. Firstly, the oil and gas industry has a huge demand for equipment replacement, especially for energy-saving transformation of old facilities. The market space is broad; secondly, with the acceleration of the development of unconventional resources such as deep-sea oil and gas and polar oil and gas, power quality equipment for special environments will become a new growth point; finally, the rise of the integrated energy service model provides an opportunity for reactive power compensation equipment manufacturers to transform into service providers.

The oil and gas industry is becoming a new growth point for reactive power compensation equipment, and this trend is driven by multiple factors. The industry's special power demand, the ever-increasing energy efficiency requirements, and the technological changes brought about by energy transformation have all created favorable conditions for the application of reactive power compensation technology in this field. For Geyue Electric, in-depth understanding of the special needs of the oil and gas industry, the development of intelligent and specialized product solutions, and the provision of full life cycle service support will be the key to seizing this emerging market opportunity. With the continuous changes in the global energy industry, the breadth and depth of the application of reactive power compensation technology in the oil and gas field will continue to expand. Our company will pay close attention to industry trends, increase technological innovation, and actively participate in standard setting to gain an advantage in the fierce market competition. In the future, Geyue Electric's reactive power compensation technology will not only become an important tool for improving energy efficiency in the oil and gas industry, but is also likely to develop into a core component of an integrated energy management system. If you have demands in reactive power compensation, please visit our website: https://www.geyuecapacitor.com/ and contact us via info@gyele.com.cn.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?