How to Reduce the Power Consumption of Low-Voltage Reactive Power Compensation Equipment Itself and Achieve "Green Compensation"?

In the current global trend of advocating energy conservation and emission reduction, the low-voltage reactive power compensation technology is undergoing a profound conceptual revolution. In the traditional view, the mission of low-voltage reactive power compensation equipment is merely to improve the power factor to avoid fines. However, a more crucial issue has long been overlooked, that is, while low-voltage reactive power compensation equipment purifies the power grid, it itself is also an energy consumer. Geyue Electric believes that promoting the transformation of reactive power compensation from a single-function type to a "green compensation" of low consumption and high efficiency is not only an embodiment of corporate social responsibility, but also an inevitable path for the sustainable development of the industry.

The Energy Efficiency Cornerstone of Core Components

The energy consumption of low-voltage reactive power compensation equipment mainly lies in its core components, especially the power capacitors and reactors. Improving the energy efficiency of the core components of the low-voltage reactive power compensation system is a solid foundation for creating a green compensation environment. The limitations of traditional dielectric materials and processes of power capacitors will lead to higher dielectric losses, and this part of the loss will continuously be converted into heat, forming the basic energy consumption during the stable operation of the equipment. Choosing low-loss capacitors with advanced metallized film and inert gas filling technology can significantly reduce the dielectric loss value, reducing this inevitable energy waste at the source. The reactor, which is matched with the power capacitor, will also bring copper loss and iron loss when suppressing harmonics. Choosing reactors made of high magnetic permeability low-loss silicon steel sheets or amorphous alloy materials, with the optimal magnetic circuit design and winding process, can minimize the heat generated under the combined action of fundamental and harmonic currents to the greatest extent.

Energy Consumption Selection of Switching Devices and System Architecture Optimization

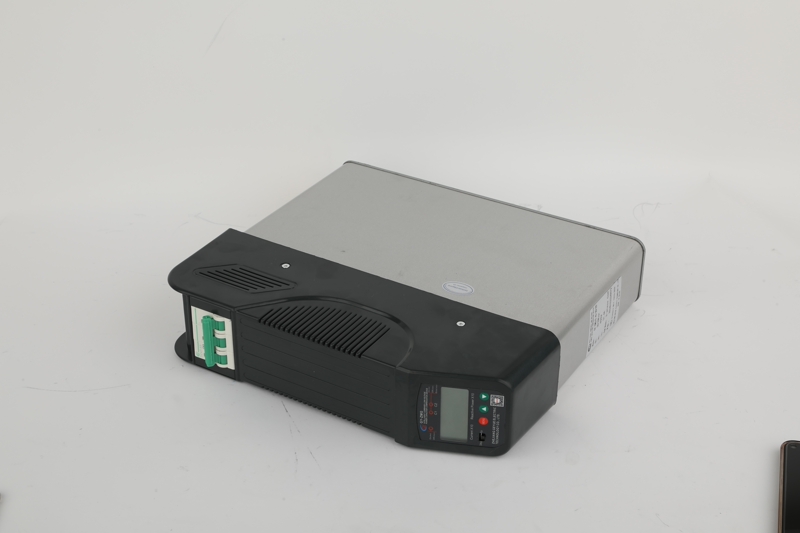

The dynamic energy consumption of the switching device is another key factor affecting the overall efficiency of the low-voltage reactive power compensation equipment. Different switching devices have different switching technical paths, resulting in significant differences in energy consumption characteristics. Traditional AC contactors consume active power continuously throughout the entire stage when the contacts are already attracted and remain closed. When the contacts are closed, although the impedance of the contactor is low, in frequent switching scenarios, the magnetic retention loss and mechanical loss accumulated due to the contactor's wear and aging cannot be ignored. Thyristor switches can achieve zero-crossing switching without moving parts, but their conduction voltage drop will generate continuous heat loss, especially in full-load or harmonic environments, where a cooling system is required, which itself brings additional air-cooling energy consumption. The composite switch attempts to integrate the advantages of both traditional AC contactors and thyristor switches, using the thyristor's triggering moment to maintain the conduction during the steady-state operation through mechanical contacts. Theoretically, it combines the advantages of semiconductor switches without inrush current and mechanical switches with low steady-state loss. The choice of which switch scheme to adopt requires comprehensive consideration of load characteristics and switching frequency, seeking the best balance between dynamic performance and static energy consumption.

The Energy-Saving Contribution of System Thermal Management and Structural Design

Excellent thermal management is a crucial guarantee for achieving low-power operation of the low-voltage reactive power compensation system. The heat generated by the internal components of the reactive power compensation equipment comes from its own losses. The accumulated heat creates a high-temperature environment, which further increases the resistance and loss of components, thus forming a vicious cycle where high temperature and high loss transform into each other. A scientifically designed passive cooling structure, such as properly planning internal ventilation ducts, providing efficient heat sinks for high-power components, or using heat-conductive metal casings, can help the system achieve effective cooling without relying on forced air cooling. When the cooling demand exceeds the passive cooling capacity, choosing efficient, low-power DC brushless fans and combining them with intelligent temperature control strategies, so that they only start, when necessary, can significantly reduce the additional energy consumption of the auxiliary cooling system. This fine design based on thermal path analysis ensures that the equipment operates stably within a lower temperature range, thereby indirectly reducing the additional losses caused by temperature rise.

Systematic Thinking towards "Green Compensation"

The efforts to reduce the power consumption of the equipment itself ultimately need to be integrated into the overall consideration of the entire low-voltage reactive power compensation system. An ideal "green compensation" system should first have a controller with excellent data processing and strategy judgment capabilities, which can precisely switch on and off according to the actual reactive power demand of the load, avoiding unnecessary energy consumption caused by excessive compensation or oscillation of switching. Secondly, in industrial environments with severe harmonic pollution, reasonable configuration of filtering branches or selection of compensation schemes with harmonic suppression functions can not only purify the power grid but also effectively reduce the additional losses caused by harmonic current on the lines and components. From the perspective of the entire life cycle, the reduction of the equipment's own power consumption in low-voltage reactive power compensation means saving operating electricity costs. Its cumulative value often exceeds the initial equipment investment difference within several years.

Geyue Electric firmly believes that "green compensation" represents the future direction of low-voltage reactive power compensation technology. "Green compensation" requires low-voltage reactive power compensation manufacturers to no longer merely focus on external indicators of compensation effectiveness, but to also examine the energy utilization efficiency of the low-voltage reactive power compensation equipment internally. By integrating low-loss components, efficient switch topologies, intelligent thermal management and systematic design, Geyue Electric is fully capable of transforming low-voltage reactive power compensation equipment from an "energy consumer" into a purer "power grid service provider". While advancing the journey of improving power quality, we also write down the footnote of energy conservation and consumption reduction. This is not only our Geyue Electric's in-depth exploration of the economic benefits for customers, but also our Geyue Electric's solemn commitment to submitting a serious pledge for building a clean and low-carbon energy system. If your low voltage reactive power compensation system requires a green compensation solution, please feel free to consult our professional technical team at info@gyele.com.cn.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?