During the Bidding Process for the Low-Voltage Reactive Power Compensation Project, Which Technical Parameters Are Most Likely to Become the Decisive Factors in Determining the Outcome?

During the bidding process of the low-voltage reactive power compensation project, the purchasing party often finds it difficult to make a choice among numerous brands and solutions. The technical proposals are usually filled with complicated parameters and extravagant promises. However, the factors that truly determine the long-term success or failure of the project are often the few core key indicators hidden behind the numerous data. As Geyue Electric, a company deeply involved in this industry for many years, we understand that a high-quality compensation project not only brings immediate compliance but also brings decades of safety, stability and energy-saving benefits. Therefore, our company suggests that the purchasing party should focus on the technical parameters that truly affect the essential performance and full life cycle cost of the reactive power compensation equipment during the evaluation process because these technical parameters are the dividing line that determines the outcome.

In-Depth Analysis of Core Compensation Performances

The top priority of low-voltage reactive power compensation equipment is to provide reactive power accurately and efficiently. Its core performances directly determine the effectiveness of power quality optimization in the power system.

The primary parameter for evaluating compensation performance is the loss value, which is directly related to the operational energy efficiency of the equipment. An excellent bidding proposal should clearly indicate the active power loss value of the entire set of low-voltage reactive power compensation devices under the rated operating conditions. The lower this active power loss value is, the less power the reactive power compensation equipment consumes itself. Consequently, the significant energy savings of the entire power system when combined with this reactive power compensation system during long-term operation will be more remarkable. The purchaser should be cautious of those proposals that merely vaguely state "low loss" but fail to provide specific measured data.

The secondary parameters for evaluating the compensation performance are the actual control accuracy and response speed of the power factor. These two factors together constitute the accuracy and reliability of the compensation effect of a compensation system. An advanced compensation system should be able to stabilize the power factor above 0.95 or even higher, rather than fluctuating widely around the qualified line. Moreover, the response speed of an advanced compensation system should be sensitive enough to changes in the load, meaning that this compensation system should be able to complete the switching action within tens of milliseconds, ensuring that there will be no problem of reactive power backflow or insufficient compensation under the condition of inductive loads.

Considerations for the Quality and Durability of Key Components

The low-voltage reactive power compensation device is not a fast-moving consumer product, whose service life often exceeds a decade. Therefore, the quality of the internal core components determines the durability and stability of the entire low-voltage reactive power compensation system.

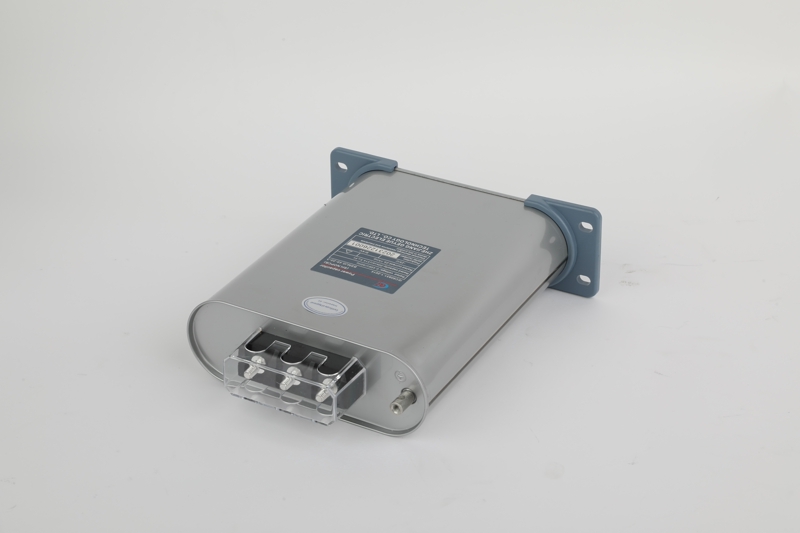

The power capacitor is the core component of the entire low-voltage reactive power compensation system. Therefore, when the purchaser considers the quality and durability of the entire reactive power compensation system, they should focus primarily on the dielectric type and design life of the power capacitor. Dry-type capacitors made of metallized film material and filled with environmentally friendly inert gas typically offer better safety, lifespan, and environmental friendliness compared to traditional oil-filled capacitors. The bidder should commit in the tender document to the expected design life of the power capacitor, such as no less than 150,000 hours, which directly reflects the manufacturing process and material standards of the power capacitors produced by this supplier.

The secondary position can affect the quality and durability of the entire reactive power compensation system precisely because of the selection of the switching device. The purchaser needs to determine the rationality of the selected switch in the bidding proposal based on the load characteristics of the project. For scenarios with stable and slow load changes, choosing a contactor as the switching device might be more cost-effective and practical. However, for scenarios with frequent load fluctuations and the need for rapid compensation, only thyristor switches or composite switches can handle the task. The purchaser should prefer the bidding proposal that can explain the basis for the selection of the switching device and present key data such as the electrical and mechanical lifespan of the switching device.

The Ultimate Guarantee for System Security and Protection Design

Safety is the unbreakable red line for all power equipment. Excellent designers of low-voltage reactive power compensation solutions will incorporate their brand's safety philosophy into every detail of the solution.

In any power system design, there must be a protection design, and this protection design must take into account the most extreme fault scenarios that may occur. For instance, the purchaser should inquire whether the power capacitors in the bidding proposal adopt a pressure-release type explosion-proof design. Because this pressure-release type explosion-proof design can release pressure through pre-set weak points in the event of an internal fault in the capacitor, causing a sudden increase in pressure, rather than allowing the entire shell to burst, thereby minimizing the expansion of the accident and ensuring the safety of personnel and equipment.

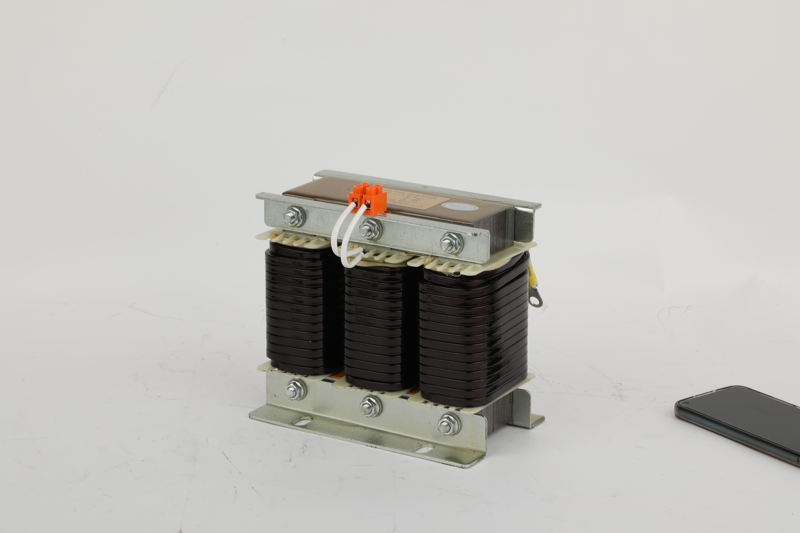

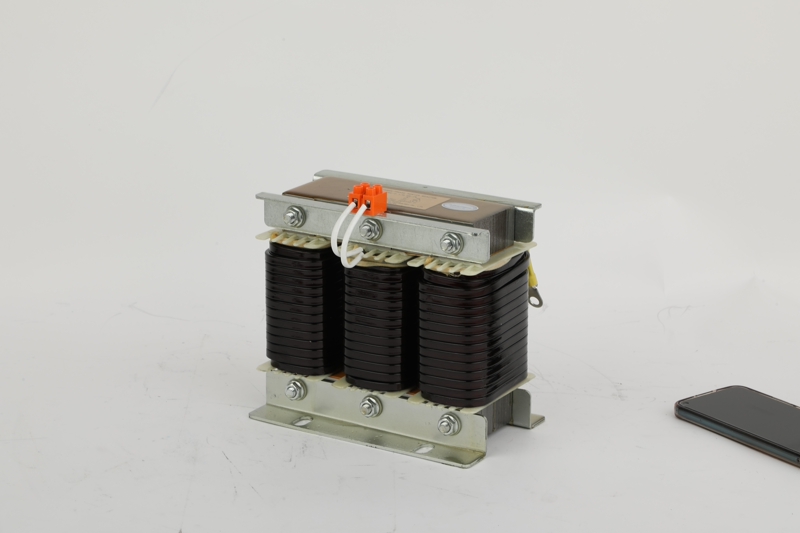

At the electrical protection level, in addition to the conventional overcurrent and short-circuit protection, a complete temperature management system is of vital importance. The low-voltage reactive power compensation scheme should describe the layout position of the temperature measurement points, the accuracy of temperature monitoring, and the triggering mechanism of overheat protection. Especially in power grids with high harmonic content, the selection rate of reactors and their own heat resistance grades are also important criteria for evaluating whether the system can operate safely and stably in the long term.

Intelligent Management and Scalable Vision

Modern low-voltage reactive power compensation equipment has already transcended the scope of a single function. Its level of intelligence determines the operation efficiency and future value. An excellent low-voltage reactive power compensation controller should possess capabilities far beyond the basic switching functions. It should be able to monitor and record key data of the system operation in real time, including power factor, harmonic voltage, current, etc., and provide clear data display and abnormal alarm functions through a friendly human-machine interface or remote interface. This highly intelligent and integrated design provides decision support for maintenance personnel and realizes the transformation from passive maintenance to proactive prevention.

Furthermore, in today's era of rapid development of the energy Internet of Things, the scalability of compensation equipment cannot be ignored. Whether the bidding proposal has reserved communication interfaces, and whether it supports accessing higher-level energy management systems or cloud platforms to achieve centralized management and in-depth mining of data all reflect the forward-looking vision and system integration capabilities of the supplier.

Geyue Electric firmly believes that the comparison of technical parameters is not merely a simple listing of numbers, but a comprehensive test of the supplier's technical strength, design concept and sense of responsibility. Geyue Electric sincerely recommends that the purchaser focus on the key indicators discussed above, which can effectively identify those low-voltage reactive power compensation solutions that truly possess long-term value and reliable quality. This will safeguard the investment throughout the entire life cycle of the project and ultimately achieve multiple goals such as safety, energy conservation, and intelligent management. If you are interested in our company's expertise in the field of low-voltage reactive power compensation, please feel free to write to info@gyele.com.cn at any time.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?