How to Achieve Efficient and Precise Management of Production Equipment?

Introduction

In the modern capacitor manufacturing industry, the precision of equipment and adherence to operational procedures directly impact product quality. Experienced engineers on the production line guide new trainees, familiarizing them with the operation of capacitor production equipment. This hands-on, mentorship-based approach ensures production accuracy and cultivates a new generation of skilled technicians. This apprenticeship model has become a key factor in maintaining the technological competitiveness of power capacitor manufacturers.

Equipment Structure and Operating Principles

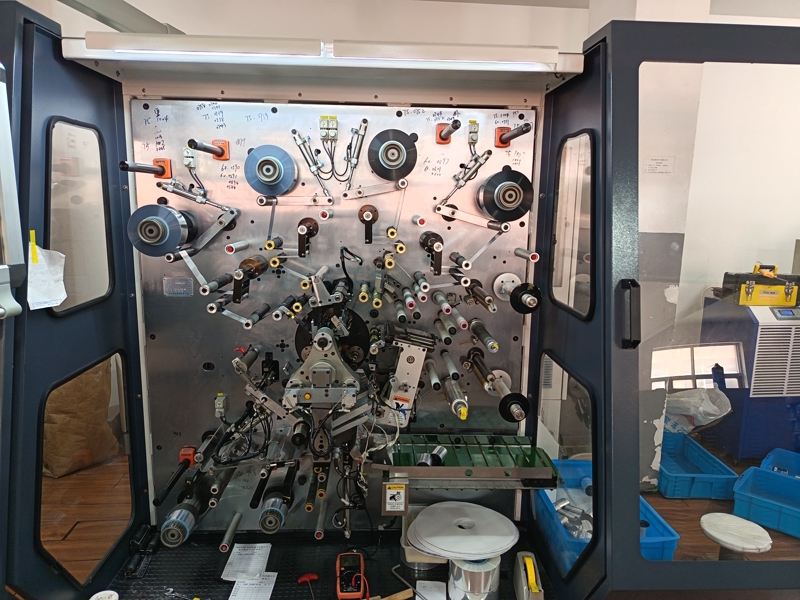

Engineers first systematically explain the overall structure and operating principles of the capacitor production equipment to the trainees. They demonstrate each key component, including the material feeding mechanism, winding unit, tension control system, and product collection device. The engineers emphasize how the winding mechanism precisely rolls the metallized film and electrolytic paper into the capacitor core, and the impact of the temperature control system on product performance. Trainees must fully understand the equipment's operating principles and the function of each component through both theoretical learning and practical experience—a fundamental prerequisite for proper operation. Only by mastering the operating principles can they accurately assess equipment status and promptly identify problems during operation.

Operating Procedures and Parameter Settings

As a power capacitor production equipment manufacturer, we place great emphasis on standardized training for equipment operation. Our training program includes a complete demonstration of the standard capacitor production process, from pre-start self-checks to normal production, and finally, shutdown and maintenance. We explain how to correctly set various process parameters, including winding tension, speed control, temperature regulation, and vacuum level. For different capacitor specifications, engineers explain the required parameter combinations and adjustment methods. Under the supervision of engineers, trainees practice repeatedly, starting with simple steps and progressing to the entire production process, until they can independently and accurately set parameters and operate the equipment.

Quality Control Key Points

Quality control is a key focus of capacitor production training. Engineers teach trainees to use various test instruments, such as LCR meters and high-voltage testers, to measure key parameters like capacitance, dissipation factor, insulation resistance, and breakdown voltage. They analyze test data with trainees, determine product quality, and explain the causes of defects and corrective actions. In addition, engineers will guide interns in conducting product appearance inspections, identifying common capacitor defects such as uneven winding, uneven terminals, and damaged casings. Through this comprehensive quality training, interns can gradually develop a strong quality awareness and learn effective quality control methods.

Equipment Maintenance and Care

Regular maintenance is crucial for ensuring the long-term, stable operation of capacitor production equipment. Engineers will demonstrate the daily maintenance procedures to interns, including cleaning, lubrication, and replacement of wear parts. They will explain the specific requirements for equipment inspections, guide interns on how to record equipment operation data, and how to identify abnormal conditions. Engineers will also teach troubleshooting methods for common malfunctions, enabling interns to independently handle simple equipment issues. This systematic maintenance training helps interns understand the importance of equipment maintenance, acquire basic maintenance skills, and lay a solid foundation for future equipment management.

Safety Standards in Production

Our company always prioritizes safety in production. During training, engineers will repeatedly emphasize safety precautions for operating capacitor production equipment, guiding interns on the correct use of protective equipment such as safety glasses and insulated gloves. They will explain potential safety hazards and preventive measures during equipment operation, teach interns emergency response procedures, and train them on how to handle emergencies correctly. This comprehensive safety training fosters a strong safety awareness and good safety practices, ensuring the safe and reliable operation of the power capacitor production process.

Conclusion

Systematic on-site training is a vital measure to improve capacitor production quality. Through the guidance of experienced engineers and standardized training procedures, interns can quickly master equipment operation skills and gradually meet the requirements of their production roles. Companies should establish a sound apprenticeship training system, develop comprehensive training programs and assessment standards to ensure the effective transmission of power capacitor production knowledge. Furthermore, continuous evaluation and improvement of training programs are essential to optimize training content and methods, laying a solid foundation for continuous improvement of capacitor manufacturing quality and promoting sustainable business development.

- How does the MODBUS-RTU Protocol Enable Three-Phase Multifunctional Meters to Be Easily Integrated into Intelligent Systems?

- The Layout Art of Components in the Low-Voltage Reactive Power Compensation Cabinet: How do Heat Dissipation, Wiring, and Safety Spacing Affect the Long-Term Stability of the System?

- What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?