What Special Designs does the Magnetic Circuit System of the CJ19 Series Contactor Have to Cope with the Greater Electromagnetic Force and Thermal Stress Generated by Frequent Switching?

In the field of low-voltage reactive power compensation equipment, the selection of contactors directly determines the stability and lifespan of the entire system. Geyue Electric, as a professional manufacturer specializing in this field, deeply understands the stringent operating conditions of capacitor switching - frequent operations several times per second, accompanied by surge currents far exceeding those of ordinary loads and thermal stresses. Today, we will analyze for you the unique and ingenious design wisdom of the magnetic circuit system of the CJ19 series contactors, which are specifically designed for capacitor switching, compared to ordinary contactors.

Enhanced Magnetic Permeability: Build a Solid Electromagnetic Framework

The magnetic circuit is the heart of the contactor, determining the efficiency and stability of the generation of electromagnetic force. The magnetic circuit of ordinary AC contactors is mainly designed for resistive or general inductive loads, and its core merely uses conventional electrical silicon steel sheets. The magnetic flux density and mechanical strength are only required to meet the general switching needs. However, the CJ19 series contactors must face completely different working conditions, namely, frequent impacts accompanied by high multiple overcurrent. Therefore, the primary principle of the magnetic circuit design for the CJ19 series contactors is "strengthening magnetic permeability ".

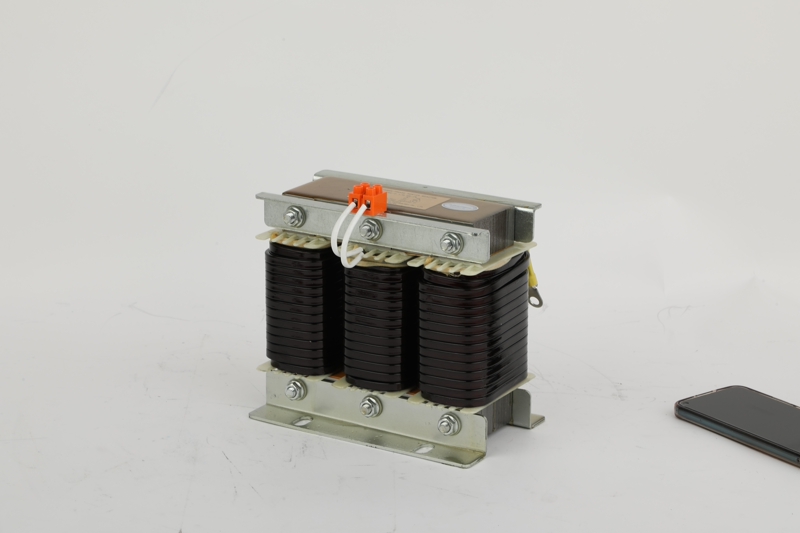

The cores of the Geyue CJ19 series contactors are made of high-grade cold-rolled silicon steel sheets with a higher grade and lower loss compared to those of ordinary AC contactors. This material not only has high magnetic permeability, enabling it to quickly establish and release strong electromagnetic attraction to safeguard reliable closure and rapid disconnection of the contacts, but also possesses higher mechanical strength and stronger impact resistance. The huge electromagnetic force generated every time a capacitor is switched on or off is uniformly transmitted through the optimized design of the magnetic yoke and core columns, effectively preventing the core from deforming or generating noise due to frequent impacts, thus ensuring the geometric accuracy and performance stability of the magnetic circuit system under long-term and frequent operations.

Optimized Heat Dissipation: Infuse the "Calm" Gene into Frequent Operations

The frequent switching operations of contactors for capacitor banks not only cause mechanical stress but also result in continuous energy losses, which will eventually be converted into heat energy. Among them, the copper loss of the contactor's coil and the eddy current loss of the contactor's iron core are the main heat sources. The heat dissipation design of ordinary contactors is usually based on the conditions of continuous power supply and intermittent operation, while the CJ19 series contactors must deal with the heat challenge posed by a reactive power compensation system operating in an almost "continuous working mode".

To eliminate the heat generated by continuous power loss, Geyue Electric has given the CJ19 series contactors a design where the magnetic circuit and the coil can work together to dissipate heat. Firstly, the coil frame and winding process of the CJ19 series contactors produced by Geyue Electric pay special attention to the thermal conduction path. Our CJ19 series products' coils use enamel wires with a higher heat resistance level than those in the market (such as H grade), and leave a better heat dissipation airway on the coil structure. Secondly, the laminated sheet process of the iron core of our CJ19 series contactors is more compact and uniform, minimizing eddy current losses. More importantly, the entire electromagnetic system of our CJ19 contactors has undergone thermal simulation optimization, ensuring that the heat generated by the iron core and the coil can be quickly dissipated to the air through the contactor base instead of accumulating inside. Our creative team has completely absorbed and integrated the "active heat dissipation" design concept, controlling the temperature rise of the CJ19 series contactors at the lowest level in history, directly delaying the aging of insulation materials and extending the service life of the coils.

Dynamic Response: Ensure Millisecond-Level Action Consistency

The switching of capacitors has extremely strict requirements for timing. The CJ19 series contactors have a unique two-step operation of "first connecting the current-limiting resistor, then short-circuiting the main contacts". This operation must be completed by the magnetic circuit system driving the mechanical mechanism with millisecond precision, which places extremely high demands on the dynamic response characteristics of the magnetic circuit.

The magnetic circuit design of ordinary contactors may focus more on the static suction characteristics, while the magnetic circuit design of the CJ19 series contactors centers on the dynamic curves during the attraction and release processes. By precisely calculating the parameters of the counterforce spring and the magnetic circuit air gap, Geyue Electric optimizes the design of the short-circuit ring to reduce AC noise and vibration. As a result, the CJ19 series contactors produced by our company operate quickly, precisely and smoothly during each closing and each breaking in frequent switching. This highly consistent dynamic performance prevents contactor contact chatter, reduces arc erosion, ensures the accurate execution of the two-step switching procedure, and directly avoids the failure of current suppression or equipment damage caused by operational errors.

Geyue Electric’s Craftsmanship: Safeguard Power Quality with Professional Solutions

As a professional manufacturer of low-voltage reactive power compensation equipment in China, Geyue Electric fully understands the significance of reliable components for the value of the system. The CJ19 series contactors of Geyue Electric are developed under the guidance of the core concepts of the magnetic circuit and overall design. They have undergone rigorous life tests and surge current impact verification, ensuring outstanding electrical lifespan and stability even in real industrial environments with complex harmonics and frequent switching. If your engineering project has not yet found a suitable low-voltage reactive power compensation system supplier, why not send your requirements to our email address info@gyele.com.cn. Our professional team will help you find the best reactive power compensation solution to improve the quality of electricity.

- Why Is the "Current-Carrying Capacity" of Capacitor Terminals a Critical Specification for Long-Term Reliability?

- Beyond the Product Warranty, What Does a "Lifecycle Support" Partnership with a Manufacturer Like Geyue Electric Entail?

- From One to 1,000: How Did the JKW5C Automatic Power Factor Controller Win Customer Trust?

- Should the Compensation Capacity Configuration Be Larger Rather Than Smaller, or Should It Be Precisely Calculated? Which Strategy Is Better?

- How to Enhance the Overall Reliability of the Compensation System? The Stability of GEYUE CJ19 is a Crucial Link.

- How Can We Effectively Educate the Market and Enable Customers to Recognize the Long-Term Value Brought by "High-Quality Compensation"?