How Can the Response Speed of Dynamic Compensation Devices Be Further Enhanced through Semiconductor Technology, Such as IGBT?

In modern power systems, the significance of power quality is becoming increasingly prominent. As a crucial equipment for ensuring the stability and efficient operation of the power grid, dynamic reactive power compensation devices play an indispensable role. Our company, Geyue Electric, as a manufacturer specializing in the research and development of low-voltage reactive power compensation equipment, has always been committed to improving product performance to meet the increasingly stringent requirements for power quality in the industrial sector. Among various technical indicators, response speed is the core factor in evaluating the performance of dynamic compensation devices, as it directly determines the device's ability to suppress voltage fluctuations, improve power factor, and respond to load changes. The traditional compensation methods based on thyristor switching capacitors or reactors are limited by the inherent characteristics of semiconductor devices, and their response time is usually in the range of tens of milliseconds, which is difficult to meet the high standards of instantaneous power quality for sensitive loads such as precision manufacturing and data centers. Therefore, exploring and applying new-generation semiconductor technologies, especially insulated gate bipolar transistors, has become the key path for us to break through the response speed bottleneck and lead technological innovation.

The Core Challenge of the Response Speed of Dynamic Compensation Devices

The core task of the dynamic compensation device is to monitor the reactive power changes in the power grid in real time and promptly generate or absorb the corresponding reactive current to achieve power balance. The bottleneck of its response speed mainly lies in two aspects: one is the rapid and accurate detection and signal processing speed of the power grid parameters, and the other is the execution speed of the power switch unit. At the signal processing level, with the application of high-speed digital signal processors and advanced algorithms, the detection delay can be shortened to milliseconds or even sub-milliseconds. However, traditional power semiconductor devices, such as thyristors, have a switching characteristic that determines they can only naturally turn off when the current is zero, which introduces an inherent delay and severely restricts the overall response performance. This delay often leads to untimely compensation when facing impulse loads with frequent and intense fluctuations, such as electric arc furnaces and large rolling mills, resulting in problems like voltage flicker and waveform distortion. Therefore, improving the dynamic performance of the power switch unit is the primary breakthrough for achieving a qualitative leap in response speed.

The Revolutionary Opportunity Brought by IGBT Technology for Improving Response Speed

IGBT, as a fully controlled power semiconductor device, integrates the high input impedance of metal-oxide-semiconductor field-effect transistors and the large current and low on-state voltage of bipolar transistors. It is applied in dynamic compensation devices, and its most significant advantage lies in breaking the limitation of the switching moment of traditional devices. IGBT can be precisely controlled by gate drive signals, enabling high-frequency on-off operations, with a switching frequency reaching several kilohertz or even higher. This characteristic brings a revolutionary change to dynamic compensation technology. It enables the compensation device to no longer rely on the zero-crossing point of the AC cycle and can quickly and smoothly regulate reactive current at any time. The converter topology based on IGBT, such as the three-phase voltage-type PWM converter, constitutes the foundation of modern static reactive power generators. SVG can continuously and continuously generate or absorb reactive power, and its response time is theoretically limited only by the operation cycle of the control system and the switching speed of the device itself. It can easily achieve a full response within milliseconds, far exceeding traditional compensation schemes.

Design Optimizations of the Gate Drive and Control System

However, merely selecting high-performance IGBT components is not sufficient to ensure that the device achieves the optimal response speed. The switching characteristics of IGBTs are highly dependent on the design of their gate drive circuits. A responsive, powerful, and well-protected drive circuit is the cornerstone for unlocking the high-speed potential of IGBTs. Our Geyue Electric has invested significant research and development efforts in drive circuit design, aiming to optimize the rising and falling edges of the drive voltage, reduce the Miller effect during the switching process, and thereby minimize the on-time and off-time of IGBTs. At the same time, the high-speed and effective short-circuit protection and overcurrent protection mechanisms ensure the safety and reliability of IGBTs in frequent and rapid switching conditions. At the control system level, we use high-speed DSP or FPGA as the core processor to execute advanced algorithms such as fast Fourier transform and instantaneous reactive power theory, to achieve real-time detection and command generation of the reactive components of the power grid. The high-speed control loop and the high-speed power switch unit work closely together to form a seamless high-speed link from "perception" to "execution", converting the hardware advantages of IGBTs into the outstanding dynamic response performance of the entire machine.

The Necessary Guarantee for Sustained High-Speed Operation Provided by Heat Dissipation Management and Packaging Technology

During high-frequency switching operation, IGBT generates significant switching loss and conduction loss, which are ultimately dissipated in the form of heat. If the heat cannot be promptly discharged, it will cause the junction temperature of the IGBT to rise, leading to performance degradation, reliability decline, and even damage to the device. Therefore, efficient heat management is a prerequisite for ensuring that the dynamic compensation device can operate continuously at a high response speed. We conduct precise thermal design using computational fluid dynamics, optimize the heat sink structure, select high-performance thermal conductive materials, and equip with intelligent air cooling or liquid cooling systems to ensure that the IGBT chip operates within a safe temperature range. Additionally, the packaging technology of IGBT also directly affects its heat dissipation capability and internal parasitic parameters. Advanced packaging technologies such as sintering technology and low-inductance module packaging not only enhance the power density and heat dissipation efficiency of the module, but also reduce the negative impact of parasitic inductance on the switching speed, making it possible for higher frequency and faster switching operations.

The Convergence Prospects of Future Wide Bandgap Semiconductor Technologies

Although IGBT technology has significantly enhanced the response speed of dynamic compensation devices to an unprecedented level, the pace of technological progress never stops. Materials such as silicon carbide and gallium nitride, which belong to the wide bandgap semiconductor category, demonstrate superior performance compared to traditional silicon-based IGBTs due to their higher critical breakdown electric field, higher thermal conductivity, and higher electron saturation drift rate. Devices like SiC MOSFETs feature faster switching speed, lower switching loss, and higher operating temperature. Integrating wide bandgap semiconductor technology into the next-generation dynamic compensation devices is expected to further reduce the response time to the nanosecond range and significantly enhance the efficiency and power density of the devices. Our Geyue Electric is closely monitoring and actively planning the application research of wide bandgap semiconductor technology, exploring its potential in hybrid compensation structures or the all-SiC/SiGa scheme, aiming to provide forward-looking solutions for the future power grid to cope with higher proportions of renewable energy integration and more complex load challenges.

In conclusion, through in-depth application and continuous optimization of the key semiconductor technology IGBT, the response speed of the dynamic reactive power compensation device has achieved a milestone leap. From component selection, drive design, control algorithms to heat dissipation management, every aspect of meticulous improvement has jointly created the device's outstanding dynamic performance. Our Geyue Electric firmly believes that innovation driven by semiconductor technology is the fundamental driving force for improving the performance of power equipment and empowering the construction of smart grids. We will continue to focus on this area and continuously convert the most advanced semiconductor technology achievements into stable, efficient, and reliable compensation equipment, contributing our professional strength to improving the power quality of the entire society and ensuring the clean and efficient utilization of power energy. If your power system needs professional support for power factor correction, please write to info@gyele.com.cn at any time, Geyue Electric is always ready to assist electricity users in every aspect of power quality optimization.

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

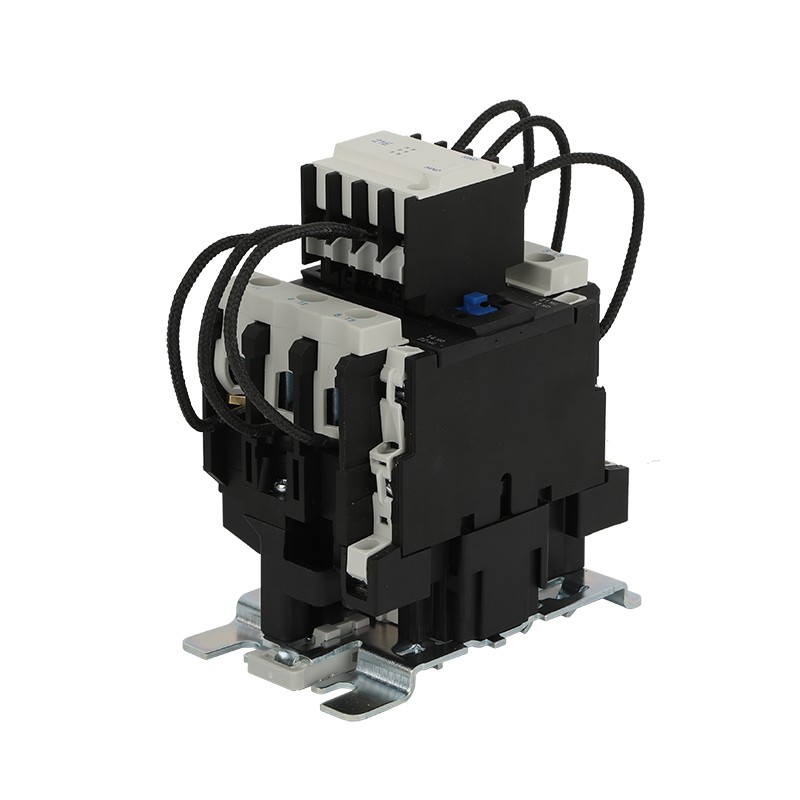

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?