How Exactly can the Problem of Excessive Capacitive Reactive Power in New Energy Power Stations Be Solved?

Driven by the "Dual Carbon" goals, China's installed capacity of new energy power generation has exceeded 700 million kilowatts, accounting for more than 30% of the country's total installed capacity. With the large-scale integration of intermittent power sources such as photovoltaic and wind power, a new technical challenge has emerged in the power system - excessive capacitive reactive power. This problem not only threatens the safe and stable operation of the power grid, but also directly affects the economic benefits of new energy power stations. Geyue Electric, as a manufacturer specializing in reactive power compensation for 15 years, in the following text, we will deeply explore a systematic solution to this stubborn problem from the perspective of engineering practice.

The Generation Mechanism of Capacitive Reactive Power Excess

New energy power generation equipment has fundamental differences from traditional synchronous generators. Photovoltaic inverters are connected to the grid through power electronic devices, and their working characteristics determine that when generating active power, inductive reactive power will inevitably be produced. Through extensive measurements, we have found that a single 2.5MW photovoltaic inverter, at its rated output, naturally generates up to 600 kvar of capacitive reactive power. For direct-drive wind turbine generators that use full-power converters, similar reactive power characteristics also exist.

This characteristic is particularly prominent in areas with concentrated new energy power stations. Last year, test data from a certain photovoltaic base in Qinghai that we collaborated with showed that during the strongest sunlight period in the middle of the day, the capacitive reactive power output of the entire power station reached 28% of the total installed capacity, causing the grid connection voltage to increase by 8.3% compared to the rated value. During the low load period at night, the problem of excess reactive power in the wind farm cluster was even more severe. A certain 500MW wind power base recorded a voltage limit violation event that lasted for 72 hours.

A Systematic Analysis of the Hazards of Excess

Voltage over-limit is the most direct manifestation of harm. When the bus voltage exceeds the +7% upper limit specified in GB/T 12325, the photovoltaic inverter will activate overvoltage protection and disconnect from the grid. We have statistically analyzed the operation data of 20 photovoltaic power stations in the northwest region, and found that the annual average power generation loss caused by voltage issues reached 1.8%.

The more serious harm lies in the progressive damage to the equipment insulation. When a transformer operates continuously at 1.1 times the rated voltage, the rate at which the polymerization degree of its insulation paperboard decreases is three times that under normal conditions. Such latent damage is often only discovered when the equipment suddenly fails. For instance, a 200MW photovoltaic power station once suffered from the breakdown of the main transformer winding due to long-term overvoltage, resulting in direct economic losses of over 3 million yuan.

Resonant overvoltage is another major threat. When the capacitive output of the new energy power station matches the inductive parameters of the transmission line, it may cause dangerous harmonic amplification phenomena. We observed in a wind-solar complementary project in Xinjiang that under a specific operating mode, the distortion rate of the 2.5th harmonic voltage suddenly increased to 12%, resulting in overheating and damage to the windings of multiple transformer boxes.

Technological Breakthroughs in Dynamic Compensation

Static Var Generator (SVG) is currently the most effective solution. Our third-generation intelligent SVG, equipped with silicon carbide power components, achieves an ultra-fast response time of less than 5 milliseconds. The unique modular design enables flexible capacity expansion, with a single unit capable of reaching up to 10 Mvar. The application of SVG in a certain ultra-high voltage supporting wind farm in Inner Mongolia has shown that after configuring a 60 Mvar SVG, the voltage fluctuation at the connection point has been reduced from 8% to within 2%.

According to different scenarios, we have developed a series of products. For distributed photovoltaic power stations, the compact wall-mounted SVG can save 60% of the installation space; for large ground power stations, the containerized integrated solution greatly simplifies the construction process. A coastal tidal flat photovoltaic project adopted our anti-corrosion SVG, and it operated continuously for three years without any faults in a salt spray environment.

System Collaborative Control Strategy

The compensation effect of a single device is limited, a system-level solution must be established. The "centralized-distributed" control system we developed coordinates the operation of multiple SVGs through a high-speed communication network. In the Hebei Zhangbei Renewable Energy Demonstration Base, this system achieved reactive power coordination for 7 new energy power stations, raising the regional voltage qualification rate to 99.9%.

The introduction of artificial intelligence technology has significantly improved control accuracy. The predictive algorithm based on deep learning can predict the trend of reactive power capacity changes 30 minutes in advance. After introducing the artificial intelligence algorithm to a certain photovoltaic power station in Ningxia, the reserve capacity requirement of SVG decreased by 35%, and equipment loss dropped by 25%. The application of digital twin technology has achieved virtual debugging, reducing the on-site debugging time by 70%.

Typical Case Analysis

The renovation project of a 200MW photovoltaic power station in Qinghai has significant demonstration value. This project adopted our "SVG + Reactor" hybrid solution, with a total investment of 8.9 million yuan. After its operation, it increased annual power generation by 46 million kWh, and the investment payback period was only 2.3 years. More importantly, it solved the voltage limit problem that had long plagued the power station, and no power outage incidents caused by voltage issues occurred again.

A certain photovoltaic-fish farming complementary project in Shandong Province has created a novel application model. By integrating the cooling system of SVG with the circulation of the fish farming area, it not only solved the heat dissipation problem of the equipment but also maintained the stable water temperature, forming a "electricity regulation + fish farming" composite income model. This design increased the internal rate of return of the project by 2.3 percentage points.

Future Technology Outlook

The deep integration of artificial intelligence and power electronics is a clear direction. The autonomous decision-making system we are developing can automatically optimize control parameters through real-time data analysis. Laboratory tests have shown that this system can increase the speed of voltage regulation by three times.

The combination of wide bandgap semiconductors and superconducting technology may lead to a revolutionary breakthrough. The low-temperature SiC-SVG developed in collaboration with the Massachusetts Institute of Technology achieves a power density three times that of conventional equipment at a working temperature of 77K. This technology is expected to solve the problem of power transmission for offshore wind power in deep waters.

Solving the problem of excessive reactive power capacity requires a combination of technological innovation and systematic thinking. Geyue Electric suggests that new energy power stations should fully consider reactive power balance requirements during the planning and design stage and select equipment suppliers with comprehensive solution capabilities. We believe that by establishing a reactive power compensation system with "precise prediction, rapid response, and reliable operation", it will provide solid support for high-renewable energy power systems. If the above article has not answered your doubts about solving the problem of excessive reactive power capacity, please further consult one of the electrical engineers of Geyue Electric at info@gyele.com.cn, we are always willing to do our best for you.

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

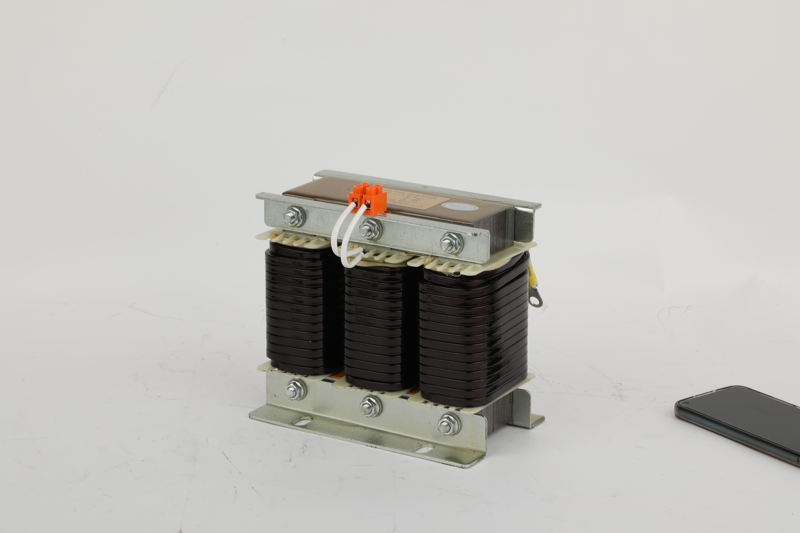

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?