What Is the Use of Three-Phase Intelligent Compound Switch?

In the power distribution rooms of factories, shopping malls, hospitals and other places, the switches that control capacitors are always in working state. Ordinary switches are easily damaged by excessive current after such frequent switching actions, which increases maintenance costs. The three phase compensation three phase compound switch has significant advantages such as no impact, low power consumption and long life, and is specially developed for controlling capacitors. This article will describe its working principle, core advantages and maintenance points in detail.

Fundamental role

The main function of the three-phase intelligent compound switch is to control the connection and disconnection between the three-phase capacitor and the power grid. When the capacitor needs to compensate for reactive power, the compound switch controls the capacitor to quickly connect to the network, and disconnects in time when compensation is not needed. The whole process is completed automatically.

Solving the core problem

When ordinary switches control capacitors, they will be subjected to a shock of dozens of times the working current at the moment of power-on. This current shock is called inrush current. Inrush current will not only burn the composite switch, but also accelerate the aging of the internal insulation of the capacitor and cause a sudden drop in the voltage of the power grid. Therefore, using ordinary switches will shorten the life of the equipment and affect the stability of the power grid.

How it works?

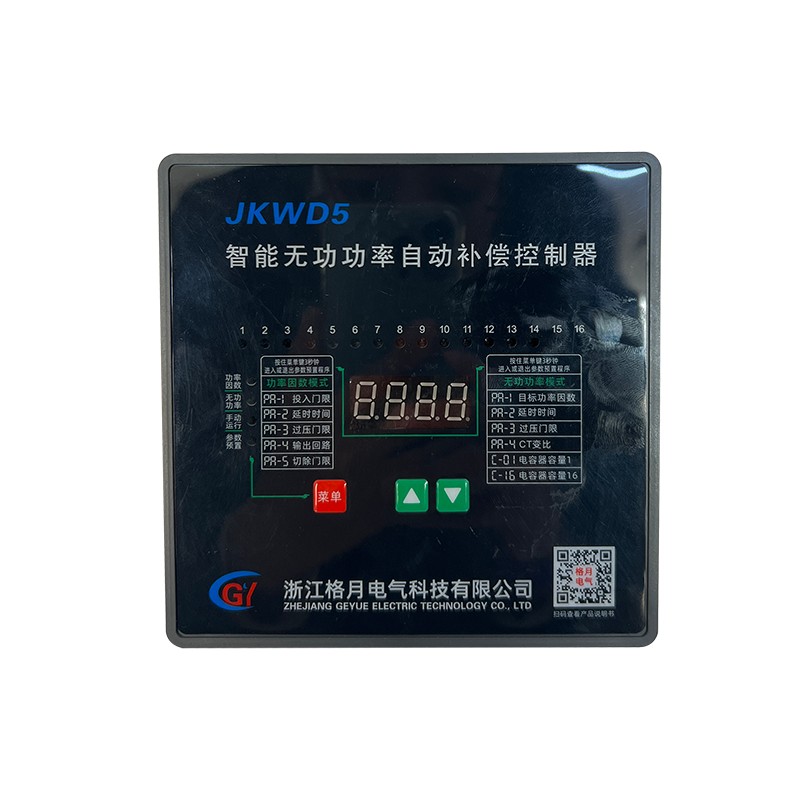

The three-phase intelligent compound switch consists of a thyristor group and a magnetic latching relay, and the two need to work together to complete the work. First, when the automatic power factor controller detects that the grid needs to compensate for reactive power, the thyristor will quickly connect the circuit to connect the current meter to the grid at the moment when the current is zero. Within 0.5 seconds after the thyristor is turned on, the contacts of the magnetic latching relay will immediately close and bear 100% of the continuous current, and the thyristor will automatically close at this time. Then when the capacitor needs to be disconnected, the thyristor will be reopened to transfer the current from the magnetic latching relay to the thyristor. When the thyristor bears all the current, the magnetic latching relay disconnects the contacts when the current is zero. The thyristor will automatically close at the next moment when the current is zero, and no arc will be generated throughout the process.

Why must the compound switch be used with a thyristor group and a magnetic latching relay? Because if there is only a magnetic latching relay, the capacitor will generate an impact of 50 times the rated current at the moment of closing, and the contacts will be welded and scrapped after several operations. If there is only a thyristor, then when the current of 100A is energized, a heat sink is required, otherwise it will burn out within 10 minutes. The energy consumption is 15 times that of the magnetic latching relay, and the cost is too high. Therefore, the thyristor group solves the safety problem of power on and off, and the magnetic latching relay solves the energy consumption problem of long-term power on. Both are indispensable.

Core Advantages

The three phase compensation three phase compound switch can completely eliminate the impact of current when switching capacitors, protecting capacitors and power grid equipment and extending its service life.

The magnetic latching relay is always disconnected under the condition of no current to avoid being burned by sparks.

The thyristor group has extremely low energy consumption during power-on, saving 90% energy compared with traditional contactors.

The system will automatically coordinate the three phases, automatically compensate for the imbalance between phases, and prevent overload of capacitors in one phase.

The status of the composite switch is monitored in real time. If an abnormality occurs, the operation will be locked immediately and an alarm will be issued in time.

Maintenance Points

The three-phase intelligent compound switch needs regular inspection and maintenance to ensure long-term stable operation. The dust on the surface of the radiator needs to be cleaned at least once every six months to prevent dust accumulation from hindering heat dissipation. At the same time, all wiring terminals need to be checked for looseness. In daily operation, the indicator light status can be used to determine whether the compound switch is operating normally. The green light indicates normal power-on operation, and the red light indicates an internal fault that needs to be repaired in time. If any abnormality is found, please disconnect the power supply immediately and contact professional staff to handle it.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?