What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?

With the continuous advancement of ecological civilization construction, the resource utilization of industrial solid waste has become an important part of green development. The self-healing shunt capacitor, as a key equipment widely used in the power system, the scientific disposal of its waste after retirement is related to major issues of environmental protection and resource recycling. Geyue Electric, as a professional manufacturer with a long history in the field of reactive power compensation, has always regarded the full life cycle management of products as the core component of corporate social responsibility, and is committed to providing customers with high-quality products that meet environmental protection standards and complete disposal guidance solutions.

Basic Disassembly and Classification Recycling Process

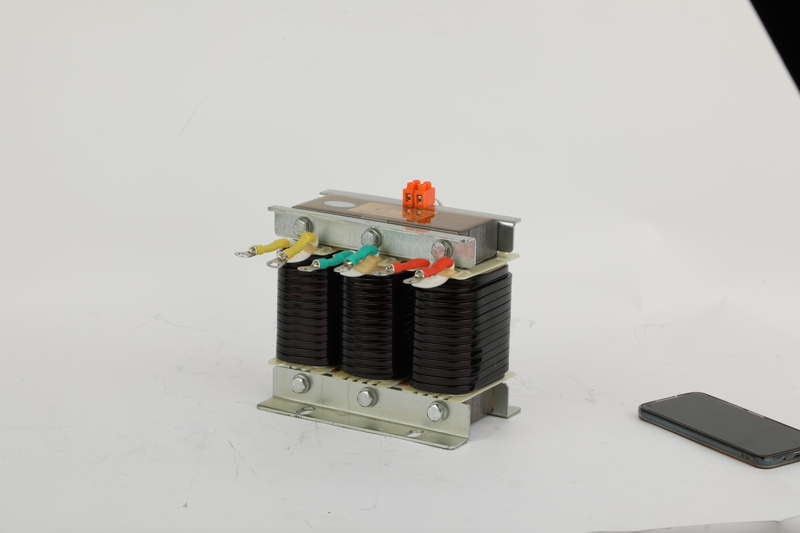

When professional recycling institutions handle scrapped self-healing shunt capacitors, they will first carry out a systematic disassembly and classification process. The staff of the recycling institutions need to use special tools to completely separate the tinplate shells of the capacitors from the internal functional components. The BSMJ series and BSMJ(Y) series self-healing shunt capacitors produced by Geyue Electric all adopt standardized iron-clad shell designs. This mature industrial material provides convenient conditions for the subsequent disassembly and classification work. The personnel responsible for separating the shells must strictly follow the regulations to classify and store the different material components such as tinplate shells, internal components, and electrical connectors obtained from the disassembly in the designated recycling containers.

The Recycling Path of Tinplate Shells

The high-quality tinplate shells used in self-healing shunt capacitors have excellent recycling and reuse value. Qualified recycling enterprises can transform these steel materials into reusable industrial raw materials through modern smelting processes. Geyue Electric attaches great importance to the recyclability of materials during the product development stage. Our BSMJ series and BSMJ(Y) series self-healing shunt capacitors have a comprehensive recycling utilization rate of the tinplate shells that can reach the industry-leading level. Since our establishment, this scientific resource recycling model followed by Geyue Electric has significantly reduced the consumption of natural resources in the manufacturing process of our new products.

Specialized Disposal of Internal Components

The recycling and reuse of the core of the metallized polypropylene filming self-healing shunt capacitors require a special processing technique. Qualified recycling and processing factories convert the organic film materials of the self-healing shunt capacitors into usable chemical raw materials through controllable pyrolysis technology. Geyue Electric always selects environmentally friendly polypropylene materials as the core media for the BSMJ series and BSMJ(Y) series self-healing shunt capacitors. This material does not produce harmful substances during the pyrolysis process, fully demonstrating our company's environmental protection design concept. The residual metal components after the metallized polypropylene film undergoes pyrolysis treatment can enter the metal recycling system for further recycling.

Recycling and Processing of Electrical Connectors

The copper terminals and internal connecting parts in self-healing shunt capacitors have extremely high recycling value. Professional recycling enterprises reprocess these metal materials into industrial raw materials through physical sorting and smelting processes. Geyue Electric prioritizes the use of recyclable electrolytic copper materials in product design. The metal connection parts of our BSMJ series and BSMJ(Y) series self-healing shunt capacitors have a surprising recycling rate of over 95%. This recycling model complies with the green manufacturing policies promoted both domestically and internationally.

The Environmental Responsibility Practice of Geyue Electric

Geyue Electric has established a comprehensive product environmental management system, covering all aspects from raw material procurement to product recycling. Our company's production base is equipped with advanced environmental treatment facilities, which can ensure that pollutant emissions during the production process meet national and international standards. Our company provides detailed environmental instructions for each batch of products leaving the factory, clearly documenting the composition of the products' materials and suggestions for recycling and disposal.

By establishing a scientific recycling and processing system, the end-of-life self-healing shunt capacitors can ultimately achieve efficient recycling and utilization of resources. Geyue Electric suggests that users prioritize the environmental performance indicators of capacitors when purchasing them. This choice not only reflects the environmental responsibility of the capacitor manufacturer but also helps to create a green and sustainable high-quality power system. Our main BSMJ series and BSMJ(Y) series self-healing shunt capacitors fully adopt recyclable tinplate shells, and their innovative structural design significantly improves the recyclability rate of the products. Choosing Geyue Electric's environmentally friendly products for reactive power compensation is an effective way for your power system to obtain a harmonious unity of economic benefits and ecological benefits. Send your power quality improvement inquiries to info@gyele.com.cn. Let's work together to build an efficient and circular power system and a clean and beautiful ecological environment.

- In the Blink of an Eye: What Are the Secrets to a CJX2 Series Contactor's "Swift, Steady, and Precise" Make-and-Break?

- How to Choose between "Stand-Alone Mode" and "Master-Slave Mode"? How Can Smart Capacitors Adapt to Different Automation Needs?

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?