How Ammeters Become the "Sensing Cornerstone" of Smart Grids?

Introduction

From ancient magnetoelectric pointer meters to today's intelligent digital instruments, current measurement technology has undergone a century of development. As a company specializing in the R&D and manufacturing of ammeters, we have witnessed the complete development trajectory of China's power instrument industry. In the 1990s, when we produced our first 0.5-class accuracy mounted ammeter, we probably couldn't have imagined that today's intelligent ammeters would achieve such diverse functions. Today, under the wave of smart grids and the Industrial Internet, ammeters have evolved from simple measuring tools into sensing terminals for power systems, posing new requirements for manufacturers like us.

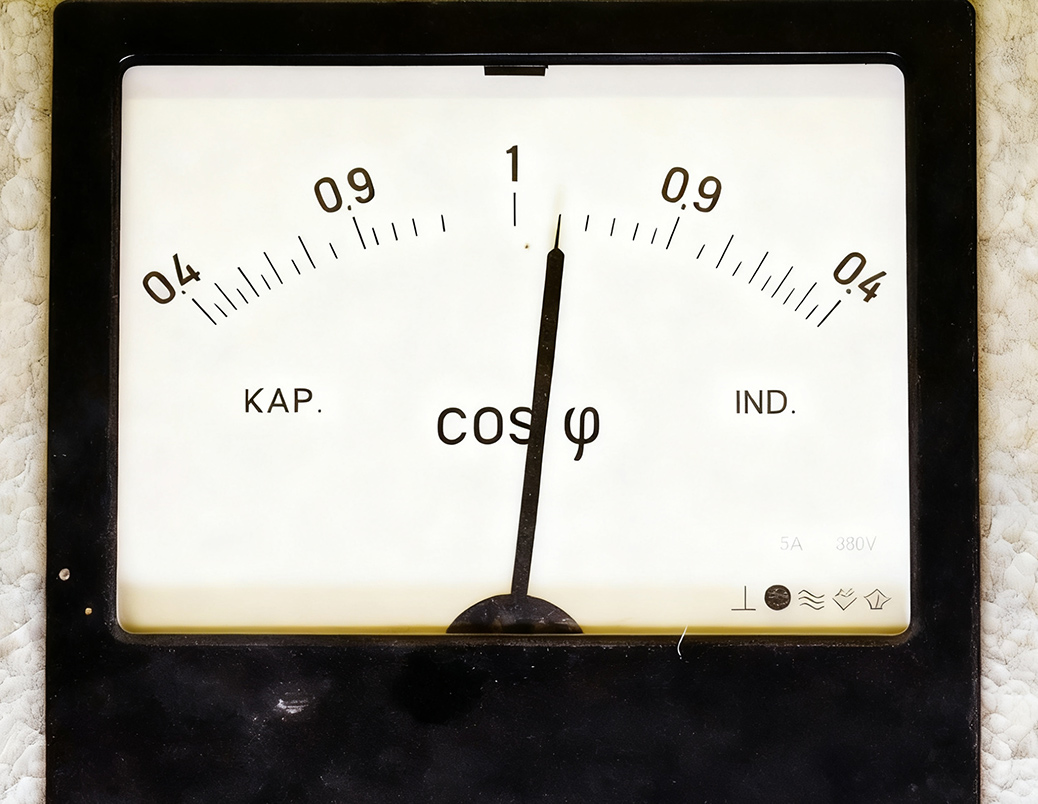

Currently, the power system is facing profound changes. The large-scale integration of new energy sources, the widespread application of frequency converters, and the ever-increasing demands of users for power quality mean that current measurement is no longer limited to simple... Reading Functions. Modern ammeters require advanced functions such as waveform acquisition, harmonic analysis, and fault recording, which presents new challenges to our technological development. Especially in complex electromagnetic environments, ensuring measurement accuracy and reliability has become a daily technical challenge.

We are proud that the technological level of domestically produced ammeters has achieved a qualitative leap. From initial imitation and learning to today's independent innovation, our product accuracy has improved from 1.0 class to 0.2S class, functionality has expanded from single measurement to multi-parameter analysis, and service life has increased from a few years to over ten years. Behind these advancements lies the result of collaborative innovation across multiple fields, including materials science, microelectronics, and communication technology.

Technological Evolution

We are particularly proud of our breakthroughs in anti-interference technology. The electromagnetic environment in industrial settings is extremely complex. For example, our newly developed Ammeter series can accurately measure fundamental current in environments with strong harmonics generated by frequency converters, a technical specification that has reached international advanced levels.

Application Scenarios In the traditional power system field, ammeters, as the most basic measuring instruments, are widely used in all aspects of power generation, transmission, and distribution. In substations, our high-precision ammeters are used to monitor line loads, providing data support for dispatching; in distribution rooms, installed ammeters help maintenance personnel understand equipment operating status; and at the user end, smart ammeters enable energy metering and power consumption analysis. Different scenarios have different requirements for ammeters, necessitating customized solutions from us.

Industrial automation is another important application area for ammeters. In smart manufacturing workshops, ammeters can not only monitor equipment energy consumption but also achieve equipment status monitoring through current characteristic analysis. Our solution for an automotive manufacturing company, by analyzing the operating current of welding robots, enabled fault early warning and preventative maintenance.

In the building sector, ammeters are integrated with energy management systems to achieve refined energy consumption management. This case fully demonstrates the value of smart ammeters in energy efficiency management.

Technological Innovation The technological innovation of smart ammeters is mainly reflected in three aspects: measurement accuracy, functional integration, and communication capabilities. Regarding accuracy, we have improved the current sensor design and signal processing algorithms, controlling the basic error of our products to within 0.2%. While this indicator may seem insignificant, for large industrial enterprises, every 0.1% improvement in accuracy can translate into significant energy savings.

Industry Trends

With the development of Industry 4.0 and IoT technologies, ammeters are facing a new transformation. We have observed several clear trends: First, the measurement accuracy is continuously improving, with 0.1-class high-precision ammeters becoming the new standard for industrial measurement. Second, there is further integration of functions; ammeters are being deeply integrated with functions such as power quality analysis and fault recording.

Future Outlook Looking ahead, ammeters will play an increasingly important role in the construction of the energy internet. With the popularization of distributed energy and the deepening of electricity market reforms, there is a need for more accurate and intelligent measurement equipment. Our technological research and development is working in this direction, and our next-generation products will support bidirectional energy metering, meeting the measurement needs of new energy facilities such as distributed photovoltaics and energy storage.

Now, our products not only meet domestic demand but are also exported to many countries and regions. Behind this achievement lies continuous technological investment and a steadfast commitment to innovation.

- In the Blink of an Eye: What Are the Secrets to a CJX2 Series Contactor's "Swift, Steady, and Precise" Make-and-Break?

- How to Choose between "Stand-Alone Mode" and "Master-Slave Mode"? How Can Smart Capacitors Adapt to Different Automation Needs?

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?