How Do Static Var Generators And Smart Capacitors Work Together To Achieve Millisecond-level Precision Compensation?

Preface

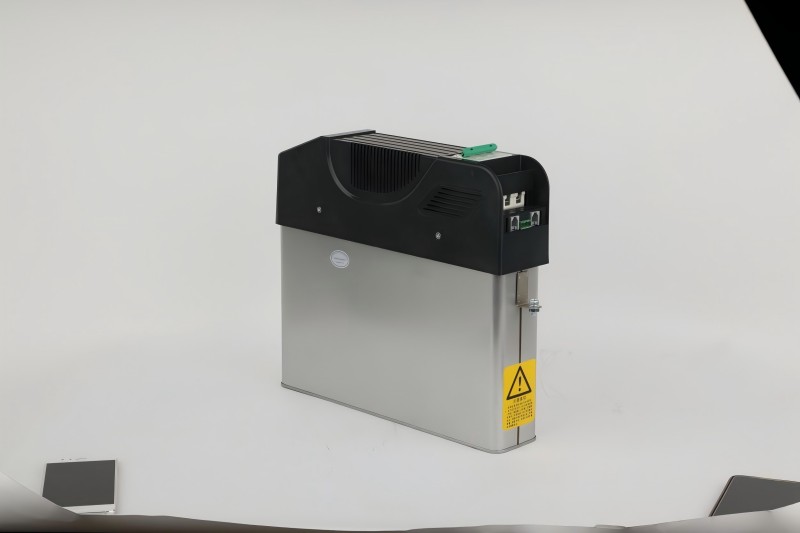

Static VAR generators (SVRs) are a core device for addressing the challenges of dynamic load compensation in modern power systems. When the power grid faces millisecond-level reactive power surges, excessive voltage flicker, or dramatic fluctuations in renewable energy power, traditional capacitor compensation devices, with mechanical response delays exceeding 200 milliseconds, are unable to effectively respond. The SVR, utilizing an H-bridge topology constructed with fully controlled IGBT power devices, achieves dynamic response within 5 milliseconds. Combined with the hierarchical compensation strategy of intelligent capacitor devices, this system provides a complete solution. This coordinated system can precisely handle challenging scenarios such as 2500 kvar 80-millisecond surges during the arc furnace melting period and minute-by-minute 30% power fluctuations at wind farms, ensuring voltage flicker is kept below 1%, meeting the stringent power quality requirements of semiconductor manufacturing and precision machining.

Core Application Scenario Criteria

Static VAR generator (SVG) deployment requires precise operating condition diagnosis. Millisecond-level impact load scenarios are determined by load fluctuations exceeding 30% per second or reactive power fluctuations exceeding 1000 kVar per 0.1 second. A typical example is an 80-millisecond gap of 2500 kVar caused by an arc furnace electrode short circuit. Critical indicators for voltage-sensitive scenarios are voltage flicker exceeding 3% or a tolerance of less than ±0.5%. For example, a single-crystal silicon growth furnace requires voltage fluctuations of no more than 1%. High-fluctuation renewable energy sites require a power ramp rate exceeding 10% per minute.

Efficient Operation Technology Principle

Our designed static VAR generator utilizes a three-level neutral-point clamped topology and achieves four-quadrant continuous regulation based on 1700V withstand-voltage IGBT power modules. The control core utilizes a dual-DSP plus FPGA architecture, performing 256 high-speed sampling cycles. Clarke and Park transforms are used to decouple and calculate instantaneous active and reactive components in real time. A key breakthrough lies in its 5-millisecond response mechanism: signal acquisition and coordinate transformation are completed within 1 millisecond of a grid disturbance, PWM modulation waveforms are generated within 2 milliseconds, and the IGBT output compensation current is triggered within a final 2 milliseconds. The system's built-in fast Fourier transform harmonic separation algorithm simultaneously filters out characteristic harmonics below the 13th order, achieving a total harmonic distortion (THD) suppression rate exceeding 90%.

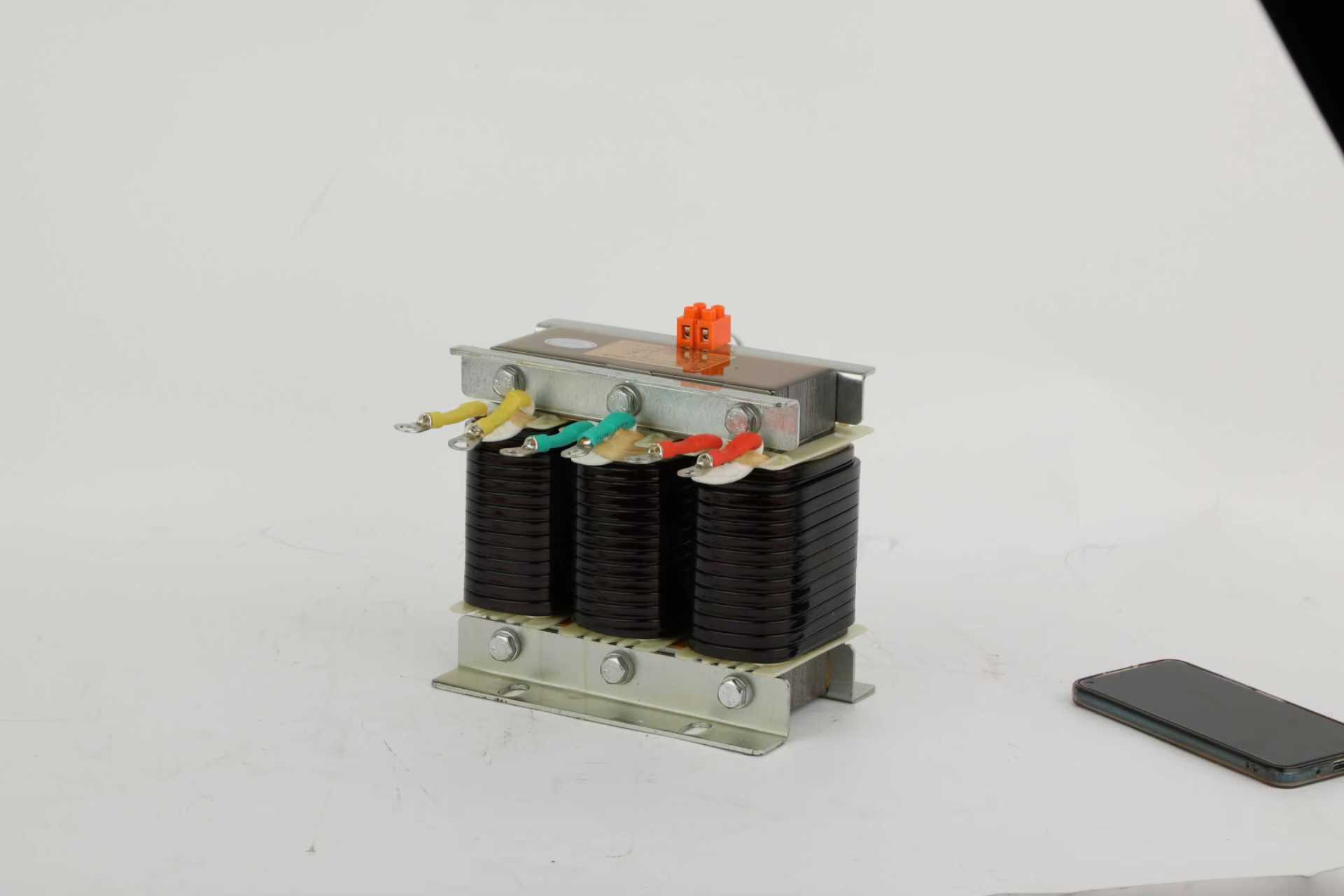

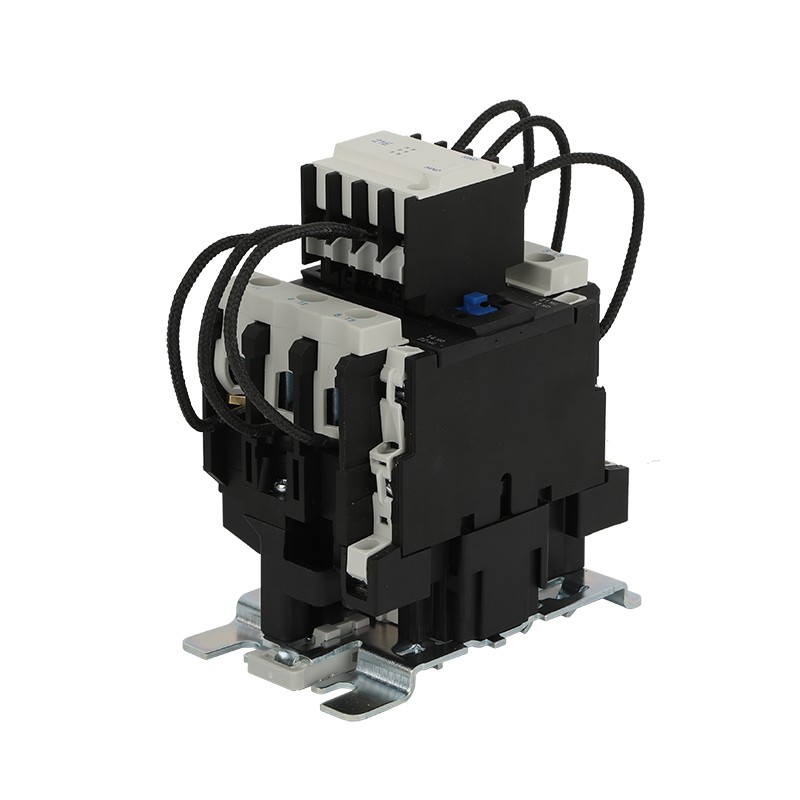

Combination of Static Var Generator and Smart Capacitor

SVG and smart capacitors combine to form a staged compensation system, maximizing efficiency. Steady-state loads are handled by smart capacitors, whose 100-millisecond response speed is achieved through magnetic latching relays and pre-charged capacitors. Capacity is calculated by multiplying the system's average reactive power by a factor of 0.8. Transient surges are primarily compensated by static VAR generators, which achieve a 5-millisecond response speed through fully controlled IGBTs. Capacity is calculated by multiplying the maximum transient surge by a safety factor of 1.2. Control coordination is achieved through fiber-optic communication. The smart capacitor controller and SVG exchange data using the IEC61850 GOOSE protocol, keeping command transmission latency within 1 millisecond. In a 1500-kW stamping press system, a 500-kvar SVG combined with an 800-kvar smart capacitor solution reduces voltage flicker from ±15% to ±2%, while also reducing contactor burnout failure rates by 92%.

Summary

As a manufacturer of static VAR generators, we solemnly promise, drawing on our 20 years of technological expertise: Each unit undergoes a 72-hour full-load shock test before leaving the factory, ensuring a precise 5-millisecond response speed. We also offer an open fiber-optic communication protocol interface, enabling 1-millisecond synchronization with intelligent capacitor devices. We maintain a full lifecycle health profile for the equipment, ensuring a fault warning accuracy rate exceeding 95%. Third-party testing confirms that the collaborative system saves 42,000 kWh of electricity annually compared to traditional solutions.

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?