How Can Compensation Intelligent Low Voltage Power Capacitor Completely Replace Traditional Discrete Systems?

Preface

Traditional low-voltage reactive power compensation systems rely on a combination of discrete components: capacitors provide capacitive reactive power, contactors perform switching operations, and controllers calculate compensation requirements. This architecture suffers from inherent drawbacks such as response lag (≥200ms), a high failure rate (12% annually), and a large footprint (standard cabinets occupy 60%). Compensation Intelligent Low Voltage Power Capacitor, through hardware integration and algorithm upgrades, replace the functions of three separate components with a single device, breaking through the bottlenecks of traditional technology.

Principle of Technological Substitution

As a capacitor manufacturer, we have achieved three core technological breakthroughs in our new generation of intelligent devices: integrating IGBT solid-state switches within the capacitor unit to replace mechanical contactors, reducing switching speeds from 200 milliseconds to 20 milliseconds; embedding a DSP processor within the capacitor module, enabling 5-millisecond harmonic analysis and reactive power calculation; and applying a 14% reactance nano-coating to the capacitor dielectric layer to directly suppress harmonics above the 23rd order and attenuate energy by 30 decibels. Simultaneously, we employ liquid metal cooling technology, reducing heat dissipation power consumption from 120 watts to 25 watts. A software system monitors the reactive power change rate in real time, dynamically combining 10/30 kvar modules to address load fluctuations. A harmonic immunity algorithm keeps grid distortion below 5%, and temperature rise monitoring provides 2,000 hours of advance warning of lifespan degradation. This solution combines the functions of reactive power compensation, harmonic filtering, and intelligent control in the capacitor, resulting in a 77% reduction in cabinet space and an 89% decrease in annual maintenance costs.

Core Performance Advantage Comparison

| Evaluation Metrics | Traditional discrete systems | Intelligent integrated device | Improvement |

| Response speed | 200ms | 20ms | 90% |

| Installation space | 0.96m³ | 0.22m³ | 77% |

| Annual failure rate | 12% | 0.7% | 94% |

| Operating energy consumption | 200W | 50W | 75% |

| Maintenance costs | $20, 000/year | $2, 000/year | 89% |

| Control accuracy | ±0.8% | ±0.3% | 62% |

Target Customer Matching Guide

As a capacitor manufacturer, we provide precise matching solutions based on our customers' specific needs. For locations where monthly distribution room rent exceeds $30 per square meter or where single cabinet space is less than 0.5 cubic meters, we recommend a compact wall-mounted unit. This capacitor integrates switching and control functions and is only 23% of the size of traditional equipment. Adoption in a commercial center saves four cabinet spaces (a total of 28 square meters), reducing annual rental costs by $20,000. If the installation space is less than 500 mm deep, a telescopic bracket can be added for wall-mounting.

For applications such as stamping presses and electric arc furnaces with load fluctuations exceeding 30%, a 5 kWh flywheel energy storage unit is essential. The capacitor bank's built-in solid-state switch has a response time of less than 10 milliseconds, synchronously triggering the flywheel to release buffered energy. After implementation in a steel plant's electric arc furnace, voltage fluctuations have been reduced from ±18% to ±4%, reducing electricity consumption by 11 kWh per ton of steel, and resulting in annual electricity savings equivalent to 65% of the equipment purchase price.

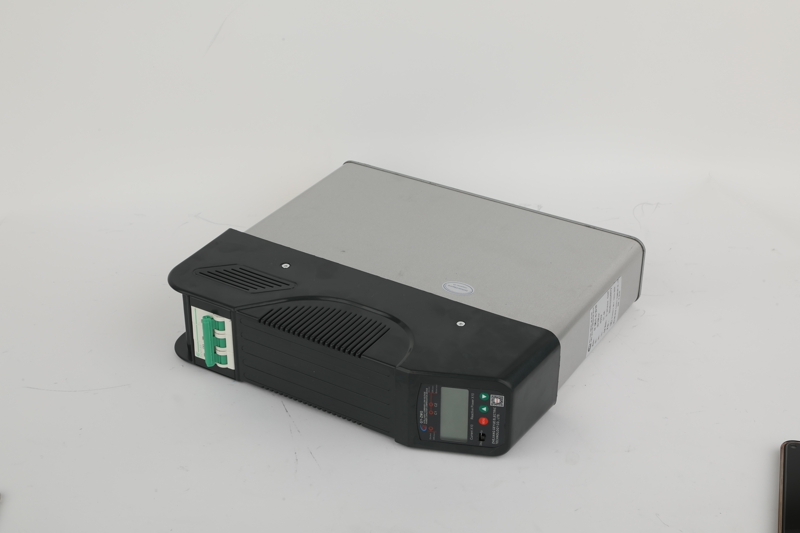

For schools, county-level factories, and other organizations without dedicated electricians, cloud-controlled capacitor devices are an option. The device transmits real-time data such as capacitor temperature and reactor vibration via a 4G network, and pushes fault codes (such as the E07 capacitor overheating alarm) directly to the administrator's mobile phone. During the hospital's 26-month operation, the capacitor failure warning accuracy rate reached 92%, eliminating the need for on-site repairs.

Authoritative Certification and Technical Endorsement

The State Grid Electric Power Research Institute's certification report confirms a response speed of 20 milliseconds. The EU CE certification verifies a salt spray life of 6,000 hours. Level 1 energy efficiency certification requires no-load losses to exceed 0.5%. The industry average payback period is 14 months, though the specific period depends on load characteristics. Charging stations have been tested and recorded in 9 months, while steel plant projects require 18 months. All technical parameters have been tested and registered by the National Electrical Product Quality Supervision and Inspection Center. The measured response speed is 18.7 ± 1.3 milliseconds, and the device has a service life of 12 years.

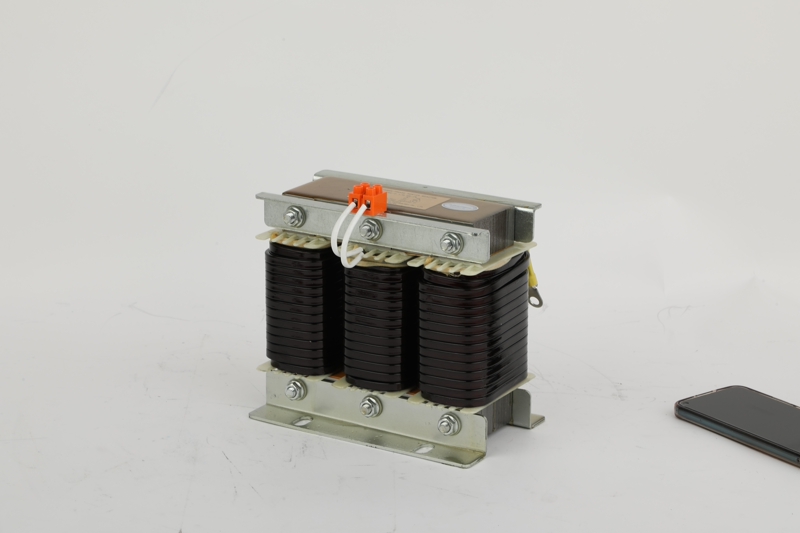

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?