Can Intelligent Low-Voltage Reactive Power Compensation Devices Become a Revolutionary Solution for Energy Efficiency Management?

Introduction

Through years of market service, we have found that industrial enterprises generally suffer from pain points such as substandard power factor, serious energy waste, and shortened equipment lifespan. Traditional compensation schemes, due to their slow response speed and low control precision, are no longer sufficient to meet the high power quality requirements of modern production. Especially with the widespread application of frequency converters and precision instruments on production lines, higher standards are being placed on the real-time performance and accuracy of reactive power compensation. This is precisely the initial motivation for our development of a new generation of intelligent compensation devices.

In terms of control algorithms, we have adopted adaptive fuzzy control technology. This algorithm can automatically adjust the control strategy according to load characteristics to achieve optimal compensation effects. Unlike traditional fixed threshold control, the intelligent device learns the operating patterns of the power grid, predicts changes in reactive power demand in advance, and achieves preventative compensation. This predictive function is particularly important in situations with drastic load fluctuations.

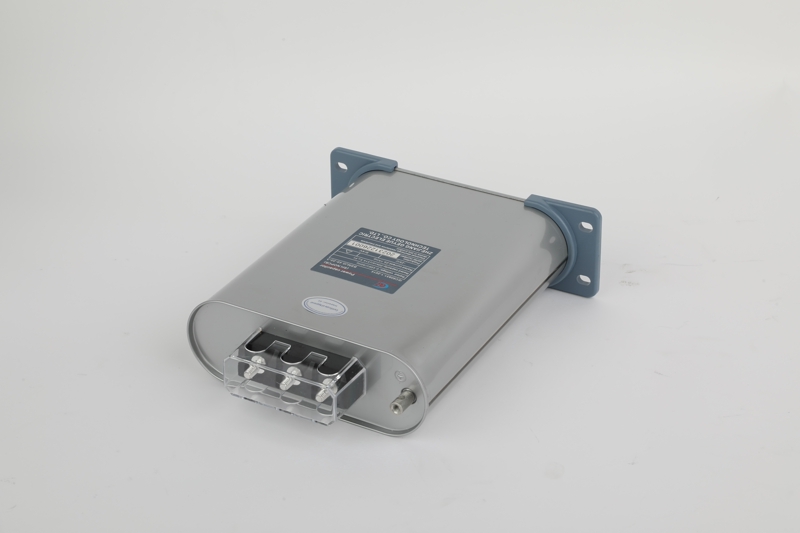

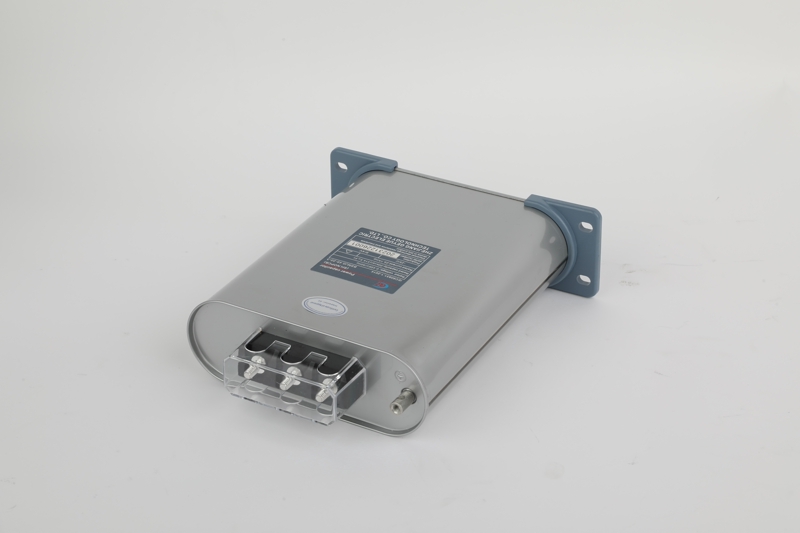

The innovations in the execution phase are equally exciting. Our developed thyristor-based switching device achieves zero-crossing switching, controlling inrush current to within twice the rated current, far lower than the 20-40 times inrush current value of traditional contactor switching. This "soft switching" technology not only protects the capacitor itself but also avoids impact on the power grid.

It is worth mentioning that the Three-Phase Compensation Intelligent Low Voltage Power Capacitor also innovatively integrates harmonic monitoring functionality. Through FFT analysis, the device can analyze the harmonic content of the power grid in real time and automatically adjust the switching strategy to avoid resonance risks. This function is of great value in industrial applications with severe harmonic pollution.

Product Features: Comprehensive Improvement Brought by Intelligence

The intelligent low-voltage reactive power compensation device is characterized by three main aspects: intelligence, integration, and reliability. In terms of intelligence, the device has self-diagnostic capabilities, capable of real-time monitoring of key parameters such as capacitor capacity decay and dielectric loss, and proactively issuing warnings when equipment malfunctions. Central air conditioning and elevators in large shopping malls and office buildings have obvious cyclical operation characteristics, and the devices can automatically adjust compensation strategies according to load changes. Practice in a large commercial complex shows that compared with traditional products, intelligent compensation devices improve energy efficiency by about 15% and significantly reduce maintenance workload.

Emerging application scenarios are also constantly emerging. In the data center sector, power quality directly impacts data security. In electric vehicle charging stations, the random start-up and shutdown of numerous charging piles can impact the power grid; the device's rapid response capabilities can effectively mitigate these fluctuations.

Of particular note is the application prospect of the Three-Phase Compensation Intelligent Low Voltage Power Capacitor in the renewable energy sector. In photovoltaic power plants and wind farms, the device can not only compensate for reactive power but also participate in voltage regulation according to grid dispatch instructions.

Implementation Case: Practical Validation from the Field

Over the past three years, our intelligent low-voltage reactive power compensation device has been successfully applied in multiple industries. A case study of a large steel company is particularly representative. The reactive power fluctuations in this company's rolling mill were extremely large, and traditional compensation devices simply could not meet the requirements. We customized an intelligent compensation solution for them, including a compensation system composed of 12 intelligent compensation devices.

The system's effects were immediate after commissioning. The power factor steadily improved from 0.68 to 0.96, with monthly electricity savings reaching 180,000 kWh. Even more surprisingly, due to improved voltage stability, the failure rate of the rolling mill equipment decreased by 30%. The company's equipment manager stated, "The intelligent compensation device not only brought direct economic benefits, but more importantly, it improved the reliability of the production line."

These success stories fully demonstrate the applicability of intelligent compensation devices in different application scenarios. More importantly, they provide reliable practical references for other potential users, enhancing market confidence in intelligent compensation technology.

Future Outlook: The Trend of Intelligent Development

With the rapid development of digital technology, intelligent low-voltage reactive power compensation devices are evolving towards greater intelligence. We anticipate several important trends in this field in the coming years. The first is the deep application of artificial intelligence technology. Through machine learning algorithms, the device can more accurately predict load changes and achieve proactive compensation. Meanwhile, AI-powered fault diagnosis will significantly improve equipment maintainability.

The second trend is cloud platform integration. Intelligent compensation devices will no longer be isolated devices, but rather nodes in the energy internet. Through cloud-based big data analysis, users can obtain more in-depth energy efficiency analysis reports and even achieve collaborative optimization across multiple sites. We have already begun our efforts in this area, and our next-generation products will support 5G communication, laying the foundation for cloud applications.

Of particular note is the advancement of standardization for Three-Phase Compensation Intelligent Low Voltage Power Capacitors. As industry standards improve, devices from different manufacturers will be able to work together better, which is beneficial to the healthy development of the entire industry. We are actively participating in the development of relevant standards to drive technological progress in the industry.

Finally, with the advancement of carbon neutrality goals, the role of intelligent compensation devices in energy management will become even more crucial. It is not merely a reactive power compensation device, but will also become a crucial data source for enterprise carbon accounting. This shift in role will significantly enhance the product's value and bring new opportunities for industry development.

Conclusion: The Era Value of Intelligent Compensation

After years of technological accumulation and market validation, intelligent low-voltage reactive power compensation devices have proven their outstanding value in practical applications. They not only overcome the technical limitations of traditional compensation schemes but also provide enterprises with new tools for energy efficiency management through intelligent functions. From a technical perspective, intelligent compensation represents a high degree of integration of power electronics, measurement and control, and information technology; from an application perspective, it embodies the evolution of equipment functions from single compensation to comprehensive management.

Looking to the future, we believe that intelligent low-voltage reactive power compensation devices will play a vital role in the construction of the energy internet. The Three-Phase Compensation Intelligent Low Voltage Power Capacitor, a key component, not only helps companies achieve energy conservation and emission reduction but also contributes to building a green and intelligent energy system. This is an era full of opportunities, and we look forward to working with partners from all sectors to create a new chapter in energy efficiency management.

- How to Choose between "Stand-Alone Mode" and "Master-Slave Mode"? How Can Smart Capacitors Adapt to Different Automation Needs?

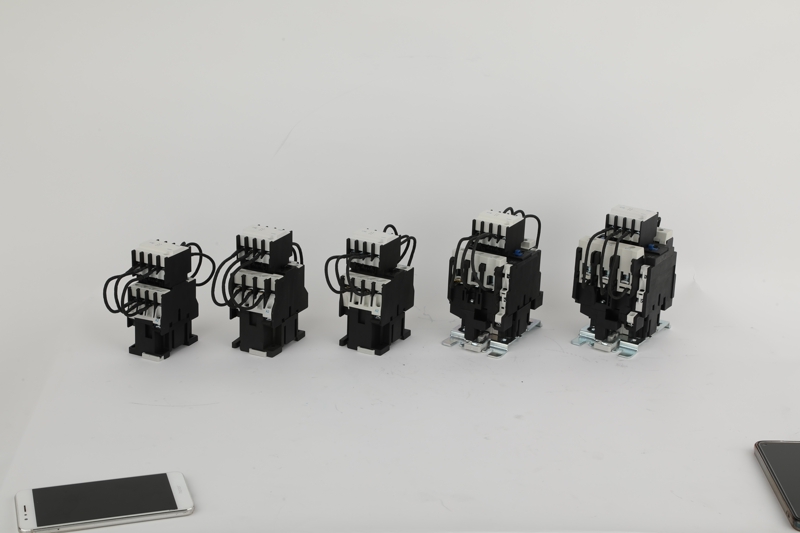

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?