Under the Concept of Circular Economy, how will the Recycling and Material Reuse Technology of Reactive Compensation Equipment Develop?

In the context of the global green and low-carbon transition, the circular economy has become a core path for sustainable development in the manufacturing industry. As a manufacturer of low-voltage reactive power compensation equipment, Geyue Electric fully understands the significance of managing the entire lifecycle of its equipment in the era of sustainable development. This article explores the development direction of reactive power compensation equipment recycling and reuse technologies from three perspectives: material regeneration technology, recycling system development, and ecological design concepts.

Innovative Breakthroughs in New Materials and Recycling Technologies

As we all know, all reactive power compensation equipment (including the reactive power compensation equipment produced by our Geyue Electric) contains a large amount of metal materials with recycling value, such as conductive materials such as copper, aluminum, and silver, as well as magnetic materials such as silicon steel and alloys. Traditional recycling methods often rely on energy-intensive processes such as high-temperature smelting. This not only consumes a lot of energy but also results in material performance degradation, completely contradicting the current trend in material recycling technology towards low-temperature separation and targeted reduction.

Low-temperature crushing and sorting technology has recently attracted much attention in the field of reactive power compensation equipment recycling. By controlling the temperature between -150°C and -196°C, low-temperature crushing and sorting leverages the differences in the cold brittleness of different materials to effectively separate metals from non-metallic materials. This novel method reduces energy consumption by approximately 40% compared to traditional pyrometallurgical methods and can achieve metal recovery rates exceeding 98%. Furthermore, low-temperature crushing and sorting technology is particularly suitable for recycling capacitors containing composite materials such as epoxy resin and ceramics.

Nano-repair technology has opened up new avenues for the reuse of precious metals. Through processes such as electrochemical deposition and plasma spraying, a nano-scale coating can be re-formed on the surface of damaged silver contacts, restoring the material's properties to over 95% of new quality. This technology greatly extends the service life of silver materials and reduces the environmental pressure caused by precious metal mining.

Intelligent Recycling Systems and Standardized Process Development

Traditional recycling models rely entirely on manual disassembly and sorting, which is inefficient and poses significant safety risks. Automation and intelligence are the two inevitable major development directions of modern recycling systems. Because intelligent and automated recycling systems can utilize machine vision and robot technology to achieve precise and intelligent disassembly, thereby liberating human resources and reducing potential risks.

The intelligent disassembly production line utilizes multi-sensor fusion technology, employing an X-ray fluorescence analyzer to rapidly identify material composition and employing a robotic arm to precisely disassemble according to pre-set procedures. This intelligent disassembly system automatically separates capacitor components, such as the aluminum casing, electrolytic paper, and electrolyte. Its processing efficiency is over 10 times that of manual disassembly, while also eliminating the risk of hazardous material leakage. Establishing a full lifecycle traceability system is crucial for the sustainable development of the reactive power compensation industry. By assigning digital IDs to key components, information such as material composition, production date, and usage status is recorded, providing data support for subsequent recycling. The good news is that Geyue Electric has embedded RFID chips in its pilot products, attempting to achieve full traceability from production to recycling.

Eco-design Concepts and Innovation in Industrial Collaborative Models

Adopting eco-design concepts from the outset is a key measure for promoting a circular economy. Considering ease of disassembly and material recyclability during the product design phase requires implementing modular architectures and standardized interface designs.

The modular design not only facilitates maintenance and upgrades but also facilitates recycling after storage. Geyue Electric's new generation of compensation devices utilizes a unified modular interface, making different models of power modules and control modules interchangeable. At the end of the compensation device's lifespan, approximately 60% of the modules can be returned to the repair market after inspection, while the remaining modules can be easily disassembled and recycled.

Establishing an industry chain collaborative mechanism is crucial. Equipment manufacturers should form a closed-loop collaboration with material suppliers and recycling companies to establish a material-level recycling system. Geyue Electric has reached agreements with several copper suppliers to use at least 30% recycled copper in new products and has also committed to recycling copper from obsolete equipment.

The concept of a circular economy is profoundly transforming the design, manufacturing, and recycling of reactive power compensation equipment. Through material technology innovation, recycling system optimization, and the promotion of eco-design, the entire industry is continuously developing in a resource-conserving and environmentally friendly direction. Geyue Electric will continue to increase its R&D investment, promote green manufacturing technology upgrades, and work with industry chain partners to build a circular economy ecosystem. We believe that through the concerted efforts of the entire industry, the reactive power compensation equipment industry will achieve both economic and environmental benefits, making its due contribution to global sustainable development. If your energy project has demands in a low voltage compensation solution, please knock knock at info@gyele.com.cn., our professional team is pleased to help at any time.

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

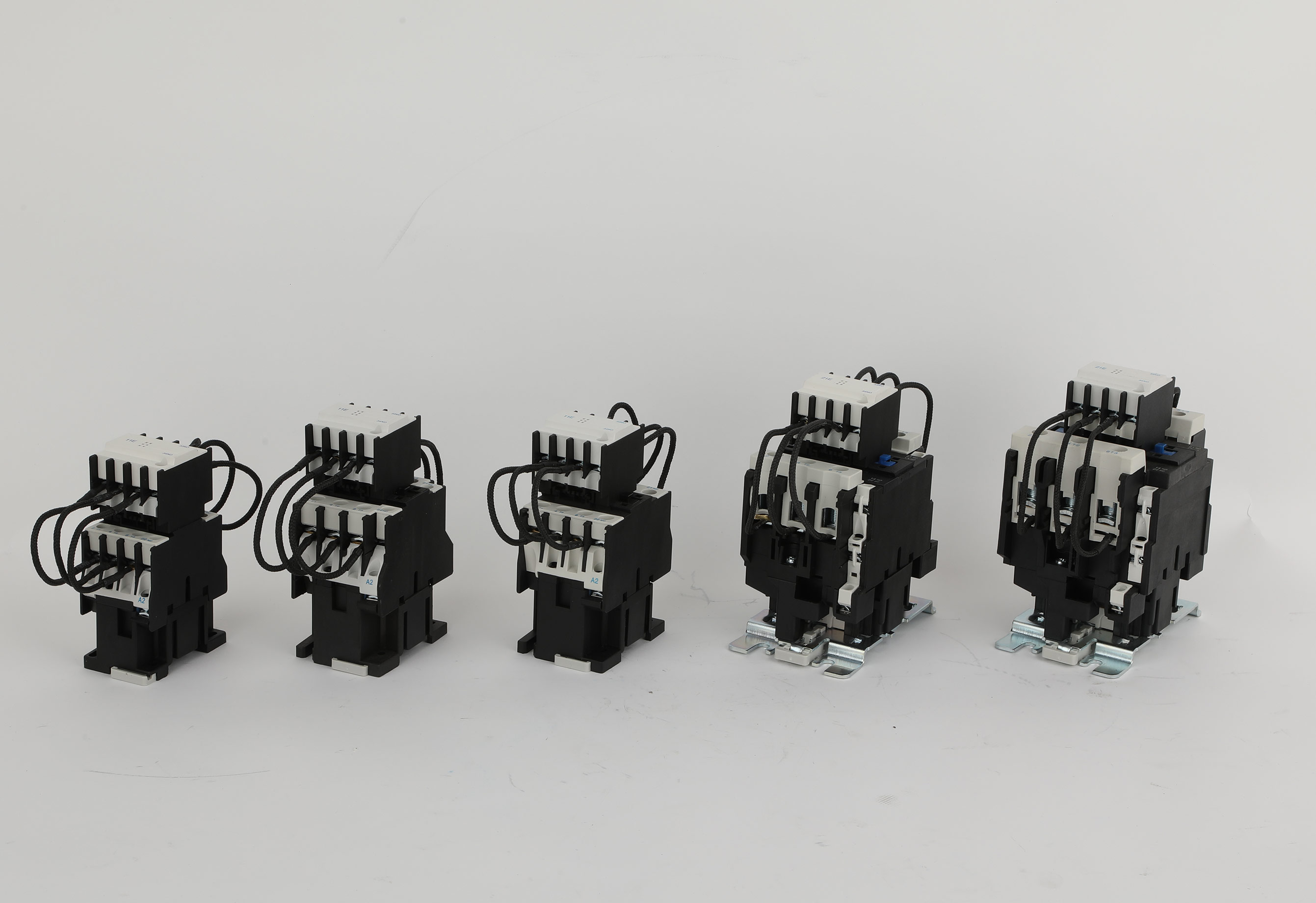

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?