What Are the Essential Checks during the On-Site Commissioning of New Capacitors?

During the on-site commissioning, conducting a series of standardized inspections on the newly purchased self-healing shunt capacitors is an indispensable preparatory task to ensure their long-term stable operation and to achieve the expected performance. Geyue Electric will systematically guide you through several essential checks that must be carried out during on-site commissioning, helping you build the first solid back line for the safety and efficiency of your low-voltage reactive power compensation system.

Essential Check 1: Verify the Initial Status

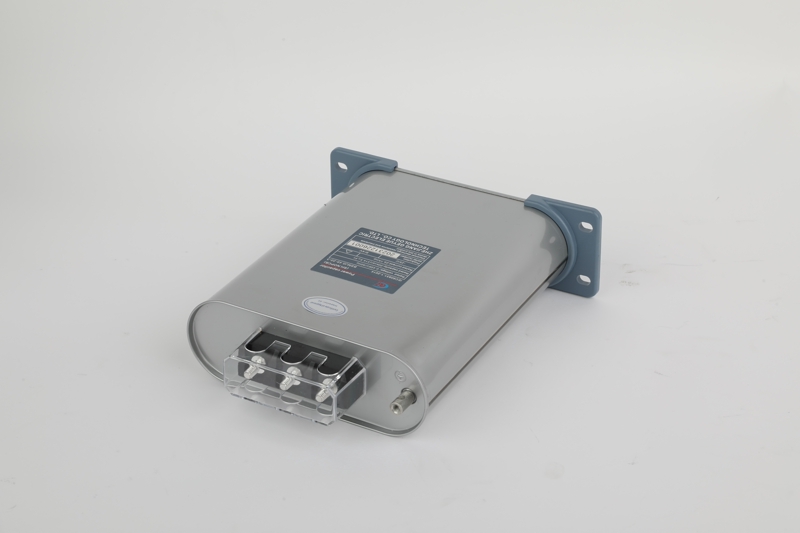

When the new self-healing shunt capacitors arrive at the project site and are ready for operation, the staff responsible for managing these capacitors should first conduct a systematic and comprehensive inspection of the appearance of the capacitors. Engineering technicians should first carefully inspect whether there are any scratches or deformations on the capacitor casing, and pay attention to whether the connection terminals are in good condition. After confirming that the appearance of the capacitor is free from any damage, the installation team, before installation, must also strictly verify whether the rated voltage and capacity parameters on the product nameplate fully comply with all the requirements specified in the design drawings of the contract. If there is any damage or discrepancy, the engineering technicians and the installation team should immediately collect relevant evidence and send it to the manufacturer to seek a solution. This first essential check of verifying the initial state will directly affect the smooth progress of the subsequent debugging work.

Essential Check 2: Verify the Electrical Performances

After completing the basic appearance inspection, the technicians must use a certified insulation resistance tester to conduct a comprehensive electrical performance test on the self-healing shunt capacitors. The testers should measure the insulation resistance value between the electrodes and the housing strictly in accordance with the standard procedures, and the reading should remain stable and above the qualified range of 1000 MΩ. Before conducting the formal wiring, maintenance personnel also need to use a digital multimeter to recheck the resistance balance between each phase of the capacitors. This second essential check of verifying the electrical performances can promptly detect potential quality issues of the capacitors.

Essential Check 3: Evaluate the Adaptability to the Installation Environment

The engineering team needs to pay special attention to the actual working conditions of the cabinet where the capacitors will be installed, make sure that there is sufficient cooling space around the equipment. Technicians should confirm that the environmental temperature of the installation site complies with the requirements of the product technical specifications. This third essential check of evaluating the capacitor adaptability to the installation environment will directly affect the service life of the capacitors. Geyue Electric suggests maintaining a cooling gap of no less than 100mm between the capacitor bank and adjacent components. Construction personnel also need to check the tightness of all electrical connection components to safeguard that the torque value of each terminal is in line with the design standards.

Essential Check 4: Test the System Compatibility

During the stage of preparing for power-on debugging, technicians should use professional power quality analyzers to record the background harmonic data of the power grid. The research data from the engineering laboratory of Geyue Electric indicates that proper system compatibility testing can prevent more than 80% of on-site failures. The debugging personnel need to confirm that the parameter settings of the reactive power compensation controller are completely matched with the actual configuration of the capacitor bank. This fourth essential check of testing the system compatibility will determine the response speed of the entire reactive power compensation system.

The modern production base established by Geyue Electric features fully automated winding lines and vacuum wax injection equipment, which secure the consistency of precision for each capacitor component. Our BSMJ series capacitors adopt a microcrystalline wax structure design, and all raw materials have passed the EU RoHS environmental certification. Our company's quality inspection center conducts strict 72-hour aging tests on every product leaving the factory. This rigorous quality control process guarantees that our capacitors can adapt to various complex industrial environments.

The comprehensive after-sales service system Geyue Electric has established can provide customers with technical support throughout the entire lifecycle. Our engineering consultant team can customize optimization plans for customers based on the on-site power quality test reports. If your project requires capacitors, why not choose Geyue Electric's self-healing shunt capacitors? Choosing Geyue Electric means you will receive comprehensive support from product selection to operation and maintenance. Your inquiries will receive the most detailed, most professional and most considerate suggestions at info@gyele.com.cn.

- How to Choose between "Stand-Alone Mode" and "Master-Slave Mode"? How Can Smart Capacitors Adapt to Different Automation Needs?

- Overload and Short-Circuit Protection in a Capacitor Circuit: How to Achieve Protection Coordination between the Upstream Circuit Breaker and the CJ19 Series Capacitor Switching Contactor?

- What does Millisecond-Level Response Mean? Why Must Dynamic Loads Pay Attention to the "Speed" of Compensation Devices?

- Reactance Rate 7% or 14%? How Should Series Reactors Be Selected to Effectively Avoid Harmonic Risks?

- Why Must Low-Voltage Power Factor Controllers Used in Photovoltaic Scenarios Be Equipped with Four-Quadrant Operation Capability?

- Why do the Mainstream Series Reactors Currently on the Market All Adopt the Dry-Type Iron-Core Structure?