How Does the CJ19 AC Contactor Drive the Electrical System?

Does your equipment in your workshop often break down? For example, when the motor starts, the AC contactor sparks and needs to be replaced every few months, or the capacitor often bulges and needs to be replaced in time. These failures are caused by the wrong selection of the AC contactor, the core control component of the electrical equipment. Choosing the right AC contactor can greatly increase the life of the equipment. The ceramic arc extinguishing cover of the AC contactor can withstand the impact of extremely high temperature arcs and effectively cut off large currents. The specially made silver alloy contacts are very durable, giving the AC contactor an extra-long life. Most importantly, the AC contactor and controller capacitor work together to significantly improve the power factor and reduce unnecessary power loss.

What is CJ19 AC contactor?

CJ19 AC contactor is an automatic switch device in low voltage compensation cabinet. It is mainly composed of three sets of main contacts, electromagnetic coil and arc extinguishing system. Its core function is to control the power on and off of motors, electric heaters and other equipment.

How it works?

When the electromagnetic coil of the AC contactor is energized, magnetic force will be generated in it, which attracts the internal iron core, and the iron core drives the three sets of main contacts until they are completely closed to form a low contact resistance path. The main circuit current flows smoothly to the load device through the closed main contacts to allow it to operate.

When the power supply of the coil is cut off, the electromagnetic attraction disappears instantly, and relying on the energy of the reset spring, the iron core and the main contacts will separate rapidly, forcibly disconnecting the load current. Current sparks will be generated when the contacts are separated, but the AC contactor is equipped with an arc extinguishing system. The ceramic arc extinguishing cover withstands the high temperature radiation and gas pressure of the arc. The built-in metal sheet can cut the long arc into multiple short arcs for forced cooling and extinguishing sparks, effectively inhibiting the dissolution and splashing of the contact metal, thereby protecting the contacts from burning and extending their life.

How do AC contactors, Automatic Power Factor Controller, power capacitors and series reactor work together?

In the low-voltage reactive power compensation system, the controller, AC contactor, capacitor and reactor work together to greatly improve the efficiency of electric energy utilization.

First, the controller is mainly responsible for monitoring the state of the power grid and continuously measuring the actual power factor of the system. When the power factor is found to be lower than the set value, the controller will output a connection signal to the operating coil of the AC contactor. Then, after the AC contactor receives the signal from the controller, its electromagnetic coil will quickly attract to close the main contact. After the main contact is closed, the main circuit current will flow to and connect the capacitor bank connected to it. After successful connection, the capacitor bank is connected to the power grid to work, neutralize reactive power, and thus improve the overall power factor. Finally, the series reactor absorbs and suppresses the harmonic current in the power grid, thereby protecting the capacitor from damage.

Through this system, the controller detects, makes decisions and issues instructions, the AC contactor executes the switch instruction, the capacitor is put into the power grid to implement reactive power compensation, and the reactor protects the capacitor. The four work together to optimize the operation efficiency of the power grid and reduce energy waste.

How to choose the right AC contactor?

There are three key points in selecting AC contactors:

1. When matching current, choose larger rather than smaller. The rated current of the AC contactor ≥ the rated current of the load * 1.25. For example, the rated current of a 55KW motor is 110A, and a AC contactor ≥ 137.5A is required. Select the 160A specification directly.

2. Select the coil voltage according to the control power supply. For example, if the power supply is 220V, choose AC220V coil, and if the power supply is 380V, choose AC380V coil.

3. Select the protection level according to the environment. If it is installed in a clean distribution box, choose IP20. If it is in a dusty environment, choose IP54 or add a protective shell.

In a sentence: It needs to be 25% larger than the load current, the coil voltage is relative to the power supply, and if the installation environment is dirty, choose high protection.

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

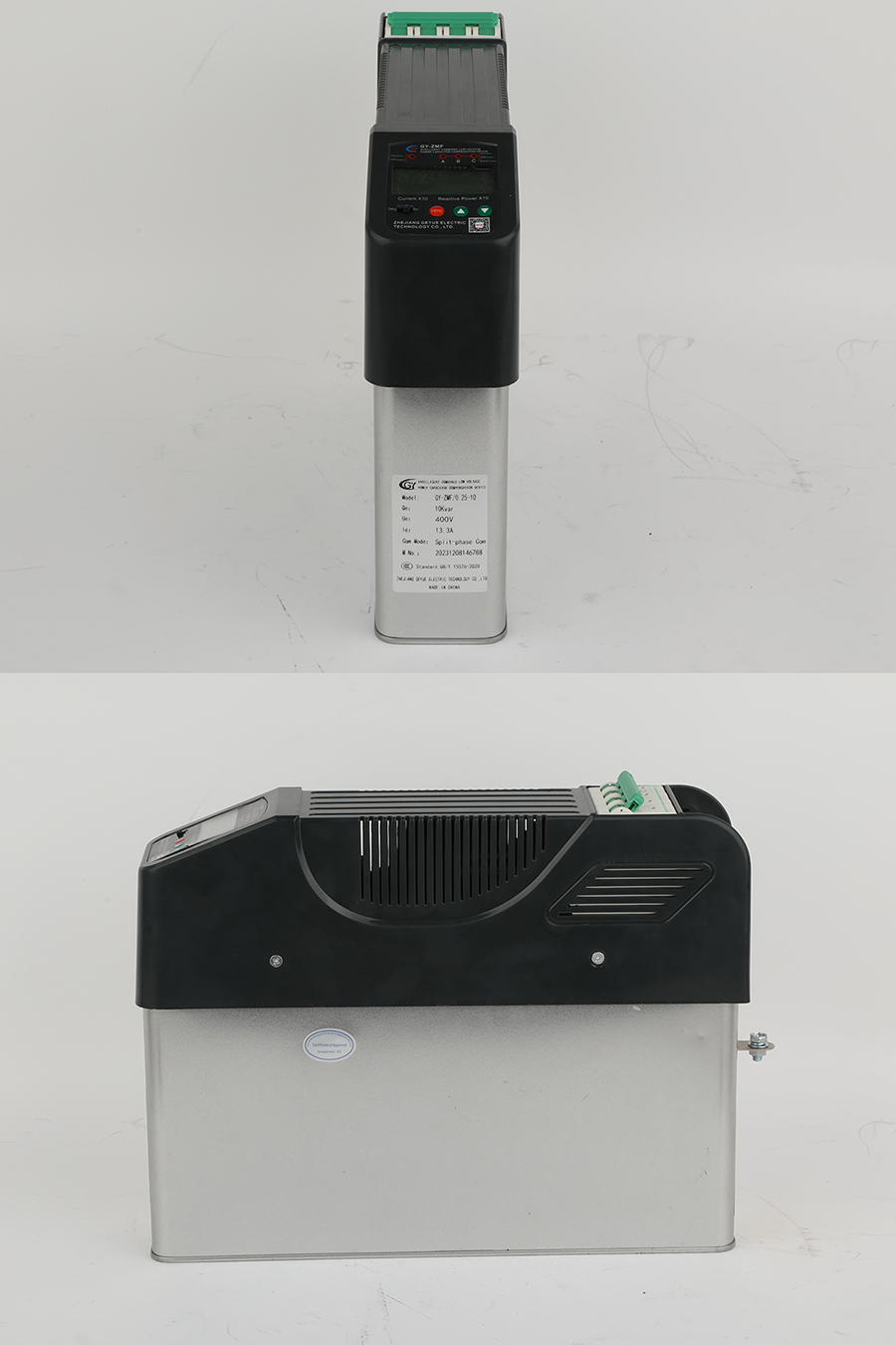

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?