How Will Reactive Power Compensation Technology Evolve Under The Dual Carbon Goals? What Are The Future Directions For Innovation?

Foreword

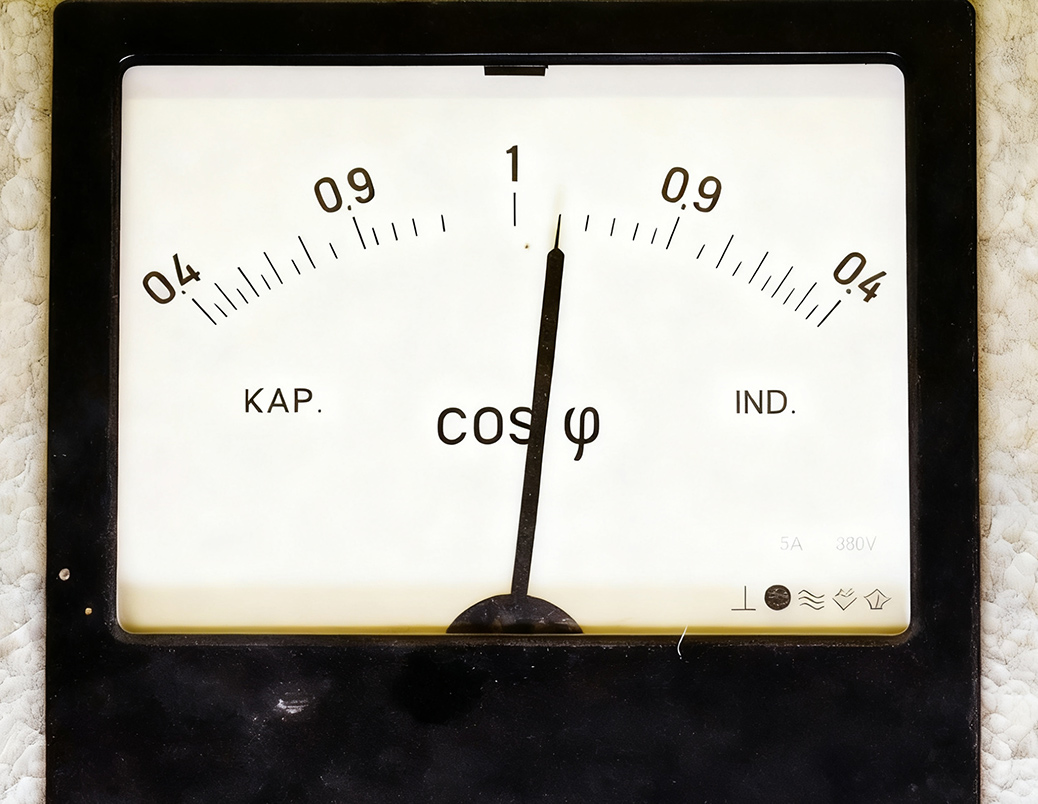

With the deepening implementation of my country's dual carbon strategy, the power system is undergoing an unprecedented green transformation. Reactive power compensation, as a key technology for improving energy efficiency, plays an increasingly important role in the construction of new power systems. The "Measures for the Management of Ancillary Services for Power Systems," jointly issued by the National Development and Reform Commission and the National Energy Administration, explicitly incorporate reactive power regulation into the ancillary service assessment system, placing higher demands on compensation equipment. This article will explore the development trends of reactive power compensation technology under the dual carbon goals and analyze future technological innovation directions.

New Requirements for Reactive Power Compensation in Energy Conservation and Emission Reduction

The dual carbon goals impose clear requirements on power system energy efficiency, and the energy consumption of reactive power compensation equipment itself has become a focus of attention. Traditional compensation devices generate significant reactive power losses during operation, which directly increase system operating costs. The new national standard imposes stricter requirements on the loss factor of reactive power compensation equipment, requiring that losses under rated conditions must not exceed 0.3%. Furthermore, the carbon emissions of the equipment throughout its entire life cycle are also taken into consideration, including material production, operating losses, and end-of-life recycling. These requirements are driving the industry toward low losses and high efficiency.

Environmentally Friendly Materials and Green Manufacturing Trends

We are actively promoting the research and development of environmentally friendly materials. The use of insulating oil in traditional power capacitors carries the risk of leakage and can pollute the environment. We are now adopting dry-type technology, using recyclable metal materials and environmentally friendly solid dielectrics. Plant-based epoxy resin is used for insulation, reducing dependence on petroleum products. Recycled aluminum alloy is used for the casing, reducing energy consumption in raw material mining. During production, we implement clean production processes to reduce wastewater and exhaust emissions and have obtained ISO14001 environmental management system certification.

Application of Digitalization and Intelligent Control Technologies

We are deeply integrating digital technology into product design. Our new generation of Intelligent Capacitor is equipped with high-precision sensors that monitor parameters such as voltage, current, and temperature in real time. Edge computing technology enables the equipment to autonomously determine switching strategies, enabling localized intelligent control. We have developed an adaptive learning algorithm that predicts changes in reactive power demand based on historical data and makes proactive adjustments. All operating data is uploaded to the cloud via an IoT platform, enabling remote monitoring and fault diagnosis. These technologies enable truly intelligent operation of the reactive power compensation system.

Development of Active-Passive Hybrid Compensation Technology

The integration of active and passive compensation technologies is becoming a significant trend. Our hybrid compensation system combines SVGs with Intelligent Capacitor, leveraging their respective strengths. SVGs provide fast dynamic compensation to cope with sudden load fluctuations, while capacitor banks provide basic reactive power support, reducing operating costs. The system utilizes a unified control platform for coordinated and optimized operation. For harmonic control, active and passive filters work together to enhance overall control effectiveness. This hybrid solution significantly reduces equipment investment and operating losses while ensuring effective compensation.

Innovation in System Integration and Energy Efficiency Management

Reactive power compensation systems are evolving from standalone operations to integrated solutions. Our energy efficiency management platform integrates reactive power compensation with active filtering, voltage regulation, and other functions. Using AI algorithms, the platform comprehensively analyzes load characteristics, electricity pricing policies, and grid requirements to automatically optimize operating strategies. The system supports coordinated control with distributed energy resources such as photovoltaics and energy storage, achieving multi-energy synergy. Through the energy management system, users can view real-time energy savings and carbon emissions data, providing a basis for carbon trading.

Standardization and Interoperability Progress

Equipment standardization and system interoperability have become key industry development priorities. We participated in developing the communication interface standard for intelligent reactive power compensation equipment, supporting interoperability with multiple communication protocols. The equipment features plug-and-play functionality, enabling rapid integration into energy management systems. Standardized design enables interoperability between devices from different manufacturers, reducing system integration challenges. We are also promoting modularization and serialization of our equipment to enhance product versatility and interchangeability.

Innovation in Operation and Maintenance Service Models

Cloud-based remote operation and maintenance services are gaining popularity. Our cloud-based operation and maintenance platform monitors equipment operating status in real time, identifying potential failures in advance. Through big data analysis, the platform predicts equipment lifespan and indicates when maintenance is needed. Users can monitor system operating status and receive early warnings via a mobile app. We provide online diagnostics and remote guidance services, reducing the need for on-site maintenance. This new model reduces operation and maintenance costs and improves service response times.

Future Technology Development Directions

We believe that reactive power compensation technology will develop in three directions. First, higher efficiency will further reduce equipment losses, with the goal of keeping losses below 0.1%. Second, it is more intelligent, leveraging AI technology to achieve predictive control and autonomous optimization. Third, it is more environmentally friendly, fully utilizing recyclable materials to achieve low carbon emissions throughout its lifecycle. Furthermore, the equipment will better integrate with renewable energy to support the development of new power systems.

Conclusion

The dual carbon goals have charted the course for the development of reactive power compensation technology. Energy conservation and emission reduction requirements are driving technological innovation in the industry, the use of environmentally friendly materials is promoting green transformation, and digital technology is enhancing system intelligence. As an equipment manufacturer, we will continue to increase R&D investment and promote product upgrades. When selecting equipment, users are advised to pay attention to energy efficiency indicators and environmental performance, choosing products that meet future development trends. Please contact us for the latest technical information and solutions.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?