Why Is It Said That in Industry 4.0 Factories, the Communication Architecture of Reactive Power Compensation Systems Must Be Restructured?

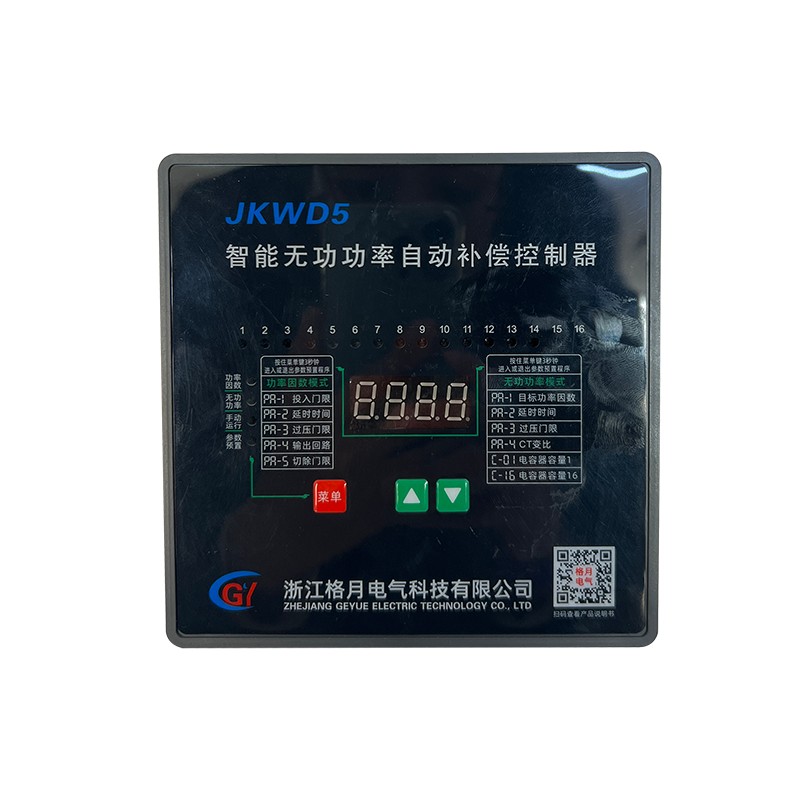

During the implementation of the Industrial 4.0 era, Geyue Electric, as a manufacturer of low-voltage reactive power compensation equipment, our company has deeply recognized that intelligence, digitization and networking have become the three most core characteristics of modern factories. The traditional communication architecture of reactive power compensation systems is no longer able to meet Industrial 4.0’s higher requirements in terms of the efficiency, flexibility and reliability of compensation. Reconstructing the communication architecture of reactive power compensation systems is not only an inevitable choice for technological upgrading in the field of power compensation, but also a key measure to enhance factory energy efficiency and reduce operating costs.

Limitations

Traditional reactive power compensation systems usually employ hard wiring or simple fieldbus communication methods, such as Modbus RTU or CAN bus. These communication methods performed adequately in the past industrial environment, but their limitations become increasingly apparent in the context of Industry 4.0. Firstly, the data transmission rate of traditional communication architectures is relatively low, which cannot meet the requirements of real-time dynamic compensation. In the Industry 4.0 environment, power load fluctuations are more frequent, and reactive power compensation equipment needs to respond quickly to grid changes. However, low-speed communication may lead to compensation delays, seriously affecting the quality of electrical energy.

Secondly, the traditional communication architecture has poor scalability and compatibility, which is not conducive to the equipment interconnection emphasized by Industry 4.0. In modern factories, there are likely to be various brands and models of power equipment. The traditional communication protocols are unable to handle this situation because the traditional communication protocols often lack standardized support, making system integration extremely difficult. Moreover, the traditional architecture is unable to support big data analysis and remote monitoring, which is precisely one of the core capabilities required by Industry 4.0.

New Requirements

The core objective of Industry 4.0 is to achieve intelligent manufacturing through data-driven methods. This trend requires that the power compensation system (which is an important part of the factory's power infrastructure) must adapt accordingly. The new communication architecture needs to meet the following key requirements.

Firstly, the new communication architecture needs to have high real-time performance and high reliability. The production lines in an Industrial 4.0 factory are highly automated, and the power load will become more dynamic. Under such circumstances, the reactive power compensation system must be able to complete data collection, data analysis, and the issuance of control instructions within milliseconds. This requires the communication architecture to support high-speed data transmission and possess redundancy mechanisms to ensure that communication does not get interrupted.

Secondly, the new communication architecture needs to be open and standardized. Industrial 4.0 emphasizes the interoperability of devices, so the communication protocol of the reactive power compensation system must support mainstream industrial communication standards, such as PROFINET, EtherCAT or OPC UA. These agreements not only enable seamless coordination connections among various devices in the power system, but also facilitate the integration benefits between the lower-level operation system and the upper-level management system (such as MES or ERP), further achieving vertical management of data.

Thirdly, the new communication architecture needs to support edge computing and cloud computing. In the context of Industry 4.0, the volume of data is growing exponentially. The traditional centralized data processing method is no longer able to meet the requirements of the new environment. The new communication architecture needs to support edge computing, which enables reactive power compensation devices to not only complete some data processing and decision-making locally, but also upload key data to the cloud for in-depth analysis and optimization.

Key Technical Path

To achieve the aforementioned goals, the reconfiguration of the communication architecture of the reactive power compensation system needs to be carried out from both the hardware and software perspectives. In terms of hardware, the traditional RS485 or CAN bus interfaces need to be upgraded to Ethernet interfaces, and even support fiber optic communication to enhance the anti-interference ability during the reactive power compensation process. At the same time, the equipment should be equipped with a high-performance processor to support edge computing functions.

At the software level, the communication protocol stack needs to be comprehensively upgraded. For instance, adopting communication protocols based on TCP/IP, such as MQTT or DDS, can achieve efficient data transmission and communication between devices. Additionally, reactive power compensation equipment should support the OPC UA standard to enable seamless integration with other intelligent devices within the factory. OPC UA not only provides a unified data model but also supports information security mechanisms, fully meeting the data security requirements of Industry 4.0.

Another key technology is the introduction of Software-Defined Networking (SDN) technology. In traditional power systems, the communication network is usually statically configured. However, in the context of Industry 4.0, network requirements may change at any time. SDN technology enables the dynamic reconfiguration of the communication network, adjusting bandwidth and routing according to real-time demands, thus ensuring that the communication of the reactive power compensation system is always in the optimal state.

Actual Benefits

Reconstructing the communication architecture of the reactive power compensation system not only overcomes the limitations of the traditional architecture, but also brings significant economic and technical benefits to the factory.

Firstly, reconfiguring the communication architecture of the reactive power compensation system can enhance the power quality and energy efficiency of the factory. A high-speed and reliable communication architecture enables the reactive power compensation equipment to more accurately track load changes and achieve dynamic compensation, thereby reducing line losses and improving power factor. Based on the actual case of Ge Yue Electric, the reactive power compensation system with the new communication architecture can stabilize the power factor at above 0.95, and reduce power loss by 5% to 10%.

Secondly, reconfiguring the communication architecture of the reactive power compensation system can significantly reduce the operation and maintenance costs of the factory. The traditional reactive power compensation system usually requires manual inspection and adjustment, while the new communication architecture supports remote monitoring and predictive maintenance. Through real-time data collection and analysis, maintenance personnel can detect potential faults in advance, avoiding sudden shutdowns. Moreover, standardized communication protocols reduce the complexity of system integration and lower the difficulty of later upgrades and maintenance.

Finally, reconfiguring the communication architecture of the reactive power compensation system can support the intelligent upgrade of the factory. Industrial 4.0 is not merely the intelligence of a single device, but the collaborative optimization of the entire production system. The reactive power compensation system, as an important part of energy management, the reconfiguration of its communication architecture lays the foundation for the factory to achieve the energy Internet of Things (EIoT). Through efficient interaction with production equipment and energy management systems, the factory can further optimize energy usage and achieve the vision of green manufacturing.

Industry 4.0 has raised higher requirements for the power infrastructure of factories, and the traditional reactive power compensation system communication architecture is no longer able to adapt to this change. As a manufacturer of low-voltage reactive power compensation equipment, Geyue Electric believes that reconfiguring the communication architecture is the only way to achieve efficient and intelligent reactive power compensation. By adopting high-speed, open, and secure communication technologies, the reactive power compensation system not only can enhance its own performance but also can provide solid support for the digital transformation of factories. In the future, with the further popularization of technologies such as 5G and artificial intelligence, our company will continue to invest in the evolution of the communication architecture of the reactive power compensation system, injecting more innovative vitality into Industry 4.0. If you are in need of a professional team to design a reactive power compensation solution that better meets the requirements of Industry 4.0 for your factory, please feel free to write to info@gyele.com.cn.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?