How Do Aluminum Core Series Reactors Overcome Industry Doubts?

Preface

Aluminum core series reactors are gradually changing the industry's traditional perception of conductor materials. Geyue Electric has achieved breakthroughs in aluminum core products in terms of conductivity, lightweight and corrosion resistance through material innovation and process optimization. This article objectively explains the technical advantages and economic benefits of aluminum core reactors.

Conductivity Improvement Solution

The aluminum core reactor uses 6101 aviation aluminum alloy conductor, and its conductivity is increased to 61% IACS, which is 23% higher than that of traditional industrial pure aluminum. The conductor structure is optimized through precision extrusion molding process, and the conductor cross-sectional area increment is strictly controlled within 10% under the premise of maintaining the rated capacity of 300kvar. The test report of the National Electrical Quality Supervision and Inspection Center shows that at an ambient temperature of 40℃, the temperature rise under rated current conditions is stable at 68K (national standard limit 95K); the temperature rise under 120% overload conditions is 89K, which is far below the safety threshold of 115K. The key breakthrough lies in the layered winding technology - the 42-slot structure makes the winding distribution more uniform and effectively suppresses eddy current losses. Comparative tests show that the harmonic filtering rate deviation of aluminum core series reactors and copper core products of the same specification is less than 0.8%, which fully meets the stringent requirements of GB/T1094.6 standard for power grid management equipment.

Lightweight economic benefit analysis

Aluminum core series reactors are 52% lighter than copper core products. Taking the 300kvar specification as an example, the weight of a single unit is reduced from 142kg to 68kg. This change triggers the economic reconstruction of the industrial chain: the optimization of the cabinet structure reduces the use of bracket steel by 37%; the freight cost of a single unit in the logistics link is reduced by 29%; the improvement in installation efficiency is reflected in the reduction of manual handling time by 66%. Energy-saving benefits are achieved simultaneously in the production link. The energy consumption of aluminum smelting is 63% lower than that of copper, and the power consumption per ton of product production is reduced by 63%. The annual power saving of large-scale production is significant.

Innovative practice of anti-corrosion technology

The oxidation problem of aluminum conductors is effectively solved by micro-arc oxidation coating technology. This process applies a high voltage current of 350 to 550 volts in a specific electrolyte to generate a 50-micron thick ceramic layer in situ on the surface of the conductor. The microhardness reaches HV1200, which is significantly higher than the HV80 level of the substrate. The coating presents a composite structure of a porous outer layer and a dense inner layer, and the porosity is precisely controlled in the range of 8% to 12%. After 3000 hours of neutral salt spray test, the insulation resistance of the coating exceeds 100GΩ, and the corrosion rate is only 0.002 mm per year, which is far lower than the 0.01 mm per year limit allowed by the national standard.

The terminal connection adopts a copper-aluminum transition composite crimping process, and the metallurgical bonding of the copper-aluminum interface is achieved by friction welding. The thickness of the transition layer is stable at 150 microns. The product has undergone 2000 thermal cycle tests, with a temperature range of minus 40 degrees Celsius to plus 85 degrees Celsius, a single cycle of 30 minutes, and the contact resistance remains below 3 micro-ohms throughout the process. In a 95% high humidity environment, the impedance spectrum test shows that the phase angle is stably maintained in the range of -80 to -85 degrees, and the frequency sweep range is 10 millihertz to 100 kilohertz. The product has passed the alternating damp heat test specified by the International Electrotechnical Commission IEC 60068-2-30 standard, completing 6 test cycles at 40 degrees Celsius and 93% relative humidity, and the insulation resistance attenuation rate is less than 0.5%.

Innovation in anti-corrosion technology for aluminum core reactors

The micro-arc oxidation coating technology generates a 50-micron thick ceramic protective layer in situ on the surface of the aluminum conductor in a 350-550 volt high-voltage electrolysis environment. The microhardness reaches HV1200, forming a composite structure of a porous outer layer and a dense inner layer, and the porosity is precisely controlled at 8%-12%. The coating has been verified by a 3000-hour neutral salt spray test, with an insulation resistance of over 100GΩ and a corrosion rate of only 0.002 mm/year, which is better than the national standard limit of 0.01 mm/year. The terminal connection adopts a copper-aluminum friction welding metallurgical bonding process. After 2000 thermal cycles from -40℃ to 85℃, the contact resistance of the 150-micron transition layer is stable below 3μΩ. The product has passed the IEC 60068-2-30 alternating damp heat test (40℃/93%RH, 6 cycles), with an insulation resistance attenuation rate of <0.5%, and an impedance spectrum phase angle of -80° to -85° in a 95% humidity environment, proving that it has long-term anti-corrosion capabilities.

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

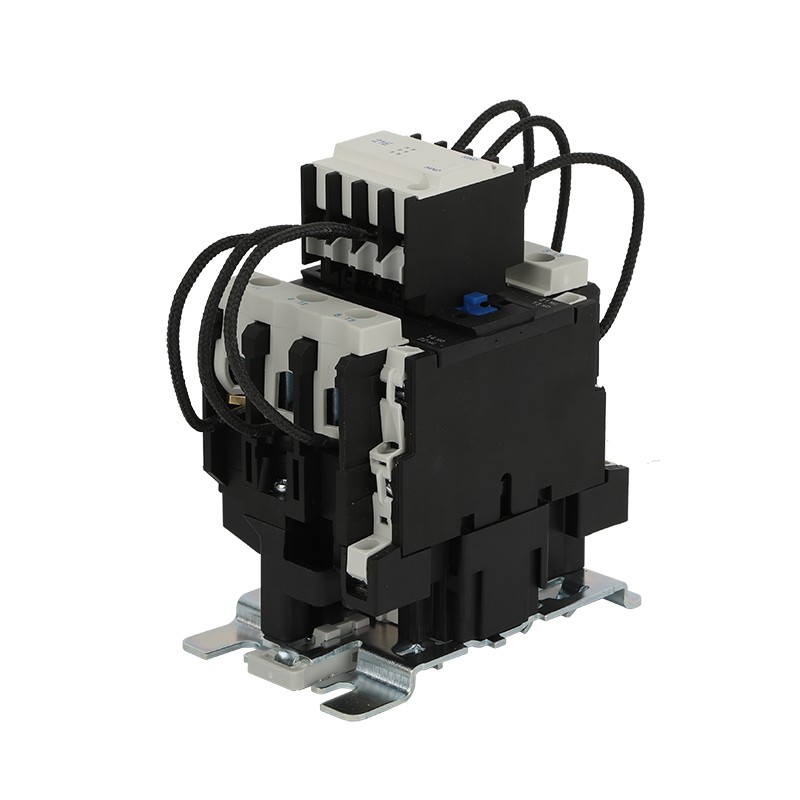

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?