How can Charging Stations Solve Power Quality Problems with the Help of Compensation Cabinets?

Preface

With the increasing number of electric vehicles, charging station power consumption issues are becoming increasingly prominent. This is especially true when multiple high-power charging stations are operating simultaneously, which can significantly impact the power grid. Compensation cabinets are a solution to these problems. They automatically adjust voltage and current to ensure a safe and efficient charging process. As a manufacturer of compensation cabinets, we frequently receive inquiries from charging station operators about these issues. Below, we'll discuss how compensation cabinets can help charging stations solve practical problems, including considerations for equipment selection and routine maintenance.

Common Power Issues with Charging Stations

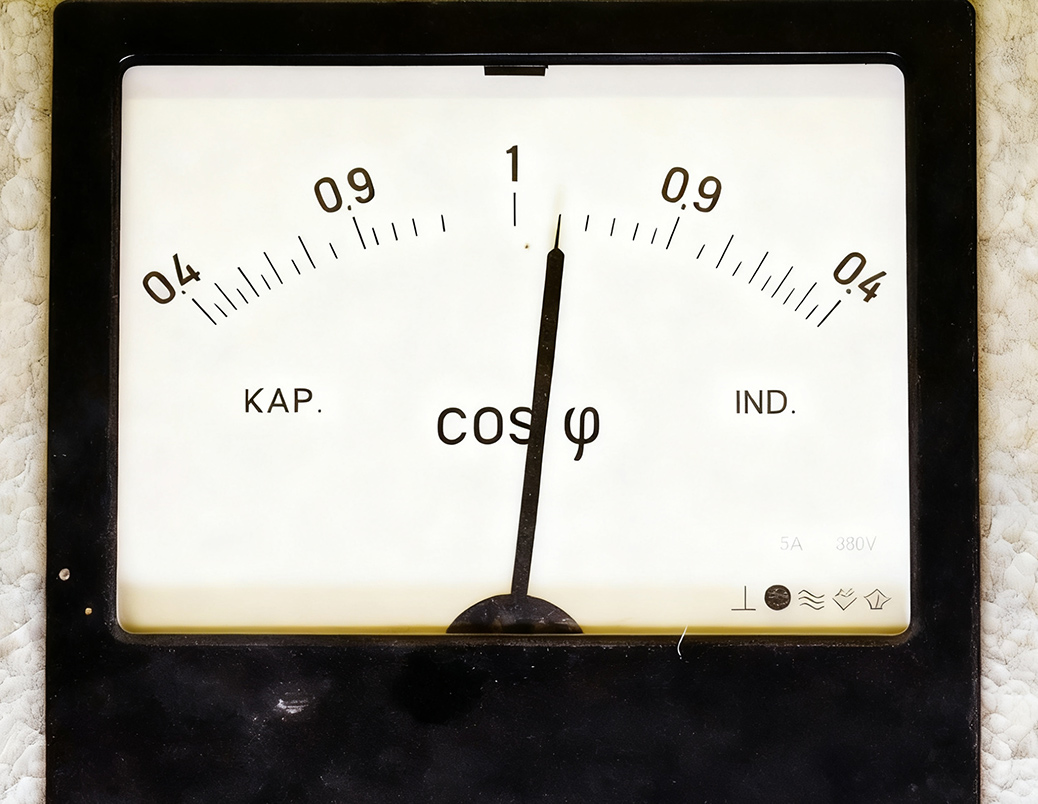

Electric vehicles are becoming increasingly popular, and charging stations are being built in ever-increasing numbers. However, many people may not be aware that these high-power charging stations place a significant strain on the power grid when in operation. Just as running multiple high-power appliances simultaneously at home can easily trip the power grid, charging stations simultaneously fast-charging multiple vehicles also put significant strain on the power grid. We often hear from charging station owners that their electricity bills fluctuate, even though the amount of electricity they charge is roughly the same. This indicates a problem with power quality. Specifically, charging stations generate a lot of inefficient energy, which reduces the power factor. Our field tests have found that a 120-kilowatt fast-charging station operating at full capacity can have a power factor of only around 0.7. This means that nearly one-third of the electricity generated is wasted, and the power grid company can impose additional penalties for this. Even more problematic, charging stations generate harmonic interference, similar to the noise on a radio, which can affect the normal operation of other equipment.

How Does a Compensation Cabinet Work?

The working principle of a compensation cabinet is actually quite easy to understand. It relies primarily on the coordinated operation of three components: power capacitors for energy storage, an intelligently controlled reactive power controller, and contactors for switching. When the system detects a decline in power quality, the reactive power controller rapidly analyzes the data and issues instructions to the contactors, instructing them to connect appropriate capacitors to the circuit. These capacitors act as "power purifiers," producing current characteristics opposite to those of the charging piles, effectively offsetting the ineffective power. We recommend selecting a controller with a fast response time, ideally within 20 milliseconds, to keep up with the rapidly fluctuating power demands of the charging piles. Be sure to select a specialized contactor; ordinary contactors cannot withstand such frequent switching.

How to Choose the Right Compensation Cabinet

As a manufacturer, we recommend that charging stations select compensation cabinets based on their specific needs. First, consider the number and power of charging piles. Generally, a station with 10 fast-charging piles requires a compensation cabinet with a capacity of approximately 200 kVar. Choose an outdoor-grade model with an IP54 rating or higher to withstand the elements. Capacitors should be of a high-quality design, as they are safer and more durable. Be sure to choose an AC contactor specifically designed for capacitor switching; ordinary contactors will burn out after a short period of use. Installation location is also crucial, preferably close to the transformer for optimal compensation. We recommend considering the location of the compensation cabinet during the planning and design phase, allowing ample space for installation and heat dissipation.

Daily Use and Maintenance Tips

After installing the compensation cabinet, daily maintenance is essential. We recommend checking operating data monthly to ensure proper compensation. A comprehensive inspection should be conducted quarterly, including cleaning dust from the cabinet and inspecting the capacitors for bulges and contact wear on the contactors. Any deformation of the power capacitor casing or unusual contactor noise should be addressed promptly. Pay close attention to the data displayed on the reactive power controller. If the power factor is consistently low, the capacitor capacity may be insufficient. During high summer temperatures, pay special attention to the cabinet's heat dissipation and ensure the vents are unobstructed.

Actual Results and Future Improvements

Our customers have shown significant results after installing the compensation cabinet. A station with 10 charging stations can save over 3,000 yuan in electricity costs per month. Furthermore, equipment operation has become more stable, and the failure rate of charging piles has significantly decreased. We are currently developing a new generation of compensation equipment, intending to combine traditional capacitors with new power electronics technology to achieve faster response speeds and meet future charging demands of 350 kilowatts and even higher. We are also developing a mobile app monitoring function that will allow charging station owners to monitor equipment operation anytime, anywhere and identify potential problems in advance.

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?