How Can the Data from Smart Capacitors Be Used for Broader Energy Analytics and Carbon Footprint Reporting?

In the modern industrial energy management field, intelligent capacitors are no longer merely the implementers of reactive power compensation. They are quietly evolving into the data nerve endings of enterprises' energy systems. These seemingly ordinary reactive power compensation devices, by continuously recording their operating status, have opened a door to deep energy cognition and precise carbon footprint management for us. Geyue Electric has deeply understood that leveraging the data from intelligent capacitors will help enterprises gain an advantage in energy conservation and emission reduction as well as sustainable development.

The Data Leap from Reactive Power Compensation to Energy Analysis

In fact, the data generated by intelligent capacitors during operation is far more valuable than we initially thought. Besides the conventional reactive power compensation parameters such as power factor and reactive power, intelligent capacitors also continuously record various rich information such as voltage harmonics, current harmonics, switching frequency, operating temperature, and their own energy consumption. The real-time data collected by these intelligent capacitors, after professional analysis, can accurately reflect the changing patterns of the load characteristics of the distribution system. By establishing a relationship model between load rate and time, power system managers can further identify the energy efficiency bottlenecks in the production process and detect potential problems of equipment running at no-load or light-load conditions. More importantly, the continuously monitored system harmonic content not only relates to power quality but is also an important indicator for evaluating energy efficiency, as harmonic current directly leads to additional line losses and energy waste.

The Data Foundation for Carbon Footprint Accounting

Under the backdrop of the Chinese government's dual carbon goals, the data collected by intelligent capacitors provides unprecedented accuracy for enterprises' carbon footprint reports. Traditional carbon emission calculations usually rely on the total electricity consumption shown in the electricity bill for estimation, while the intelligent capacitor group offers detailed electricity usage profiles broken down by time periods and quality. By analyzing the dynamic changes in compensation capacity, power system managers can reverse calculate the specific energy consumption distribution of different production processes. This real-time data-based analysis method enables enterprises to precisely allocate the total carbon emissions to each product line or production stage. Additionally, power system managers can compare the system loss changes before and after installing intelligent capacitors to directly quantify the energy-saving effect brought by reactive power compensation and convert it into verifiable carbon emission reduction, providing convincing data support for enterprises' environmental responsibility reports.

Value Creation in Data-Driven Decision-Making

Beyond the traditional reporting functions, the data collected by intelligent capacitors is becoming an intelligent source for enterprises' energy decision-making. The long-term accumulated operation data of intelligent capacitors can help enterprises establish their own energy efficiency baseline. When there is a significant deviation between the real-time energy consumption and this baseline, the reactive power compensation system can immediately issue an alert, indicating that there may be equipment failures or process abnormalities in the power system that require attention by the energy system managers. The predictive model trained based on historical data can also combine production plans to predict the energy consumption trends in future periods, providing decision-making basis for participating in the demand-side response of the power grid or formulating power purchase strategies. This transformation from passive compensation to active optimization has enabled energy management to truly achieve a leap from a cost center to a value creation center.

Data Empowerment of Geyue Electric’s Intelligent Capacitors

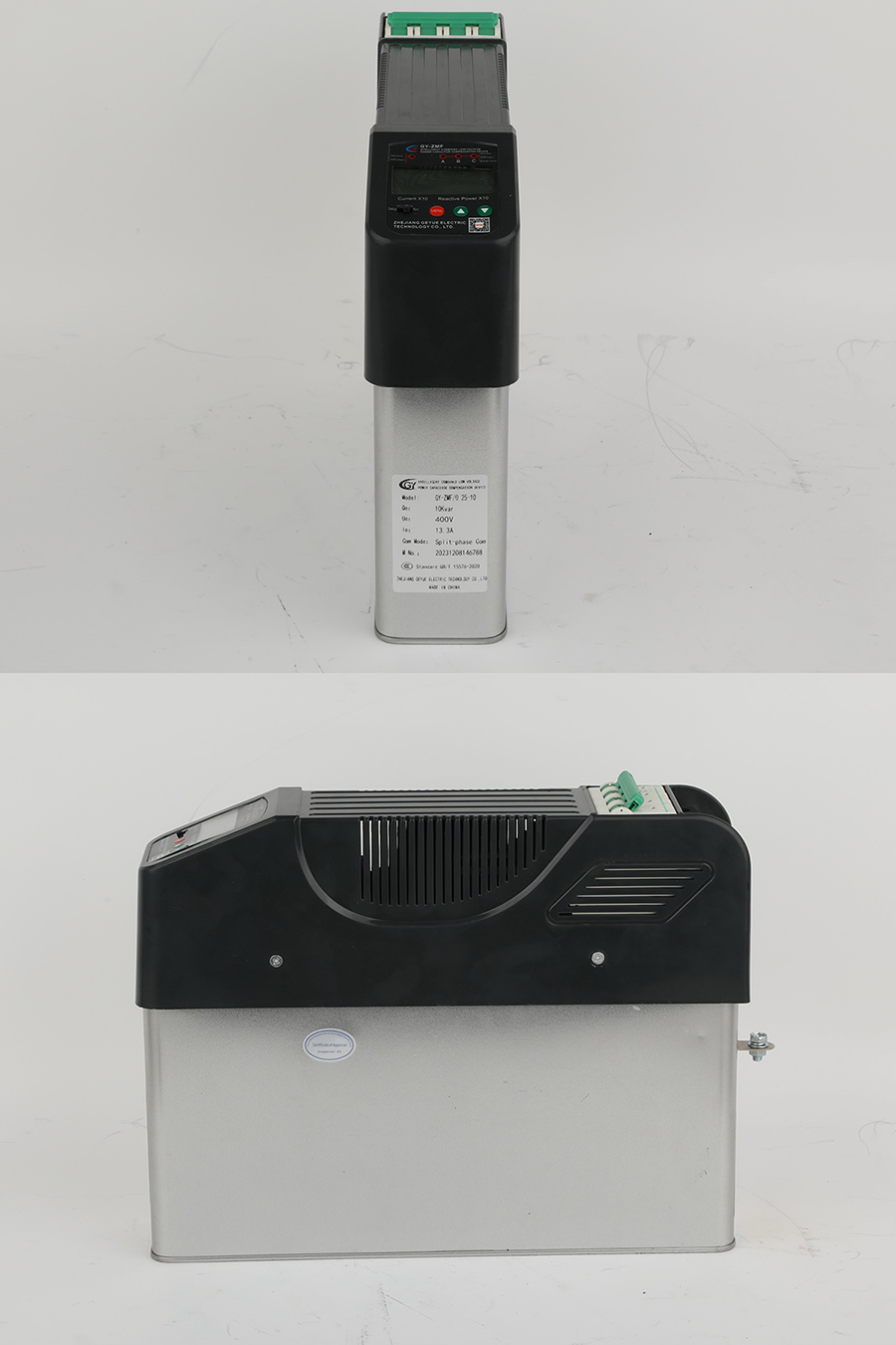

At Geyue Electric, thanks to our unique insight that data value holds a central position in modern energy management, we have designed and developed the GYZMG and GYZMF series of intelligent capacitors that perfectly embody this industrial product concept. These two intelligent capacitor series, launched by our chief engineering team, not only possess outstanding reactive power compensation performance, but also incorporate high-precision data acquisition and advanced communication modules.

Geyue Electric sincerely invites you to experience the data value brought by our intelligent capacitors and our one-stop low voltage reactive power compensation system. Now, drop your inquiries to info@gyele.com,cn, let our professional low voltage reactive power compensation devices become the intelligent foundation of your enterprise's energy management, and let us jointly embark on a more efficient, more transparent and more sustainable energy future.

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?