How to Use Compound Switches with Capacitors for Switching

Introduction

Capacitor switching has always been a headache in power systems. The old methods often generated large current surges and sparks, which not only affected equipment life but also caused grid voltage instability. Now, with the advent of new devices like compound switches, these problems are cleverly solved, making capacitor switching safe and reliable.

In our many years of experience working with power equipment, we've witnessed countless equipment failures caused by switching issues. Capacitors generate a large surge current when energized, dozens of times greater than the normal operating current, easily damaging the equipment. Sparks generated during power outages can also slowly burn out the switch contacts. The advent of compound switches has truly solved a significant problem.

What are the problems encountered when switching capacitors?

The moment power is applied to a capacitor is the most dangerous, as it generates a very large surge current. This surge current is so powerful, like suddenly turning on a high-pressure water tap, it can easily damage the equipment. It also causes voltage fluctuations, similar to the flickering lightbulb when turning on the air conditioner in your home. Power outages can generate sparks, which can burn out switch contacts over time.

These problems will reduce the service life of the equipment and increase the maintenance cost. We have encountered many capacitors that failed prematurely due to switching problems. Some customers even suffered production interruptions due to frequent maintenance. Therefore, the correct switching method is crucial.

How to operate the compound switch correctly

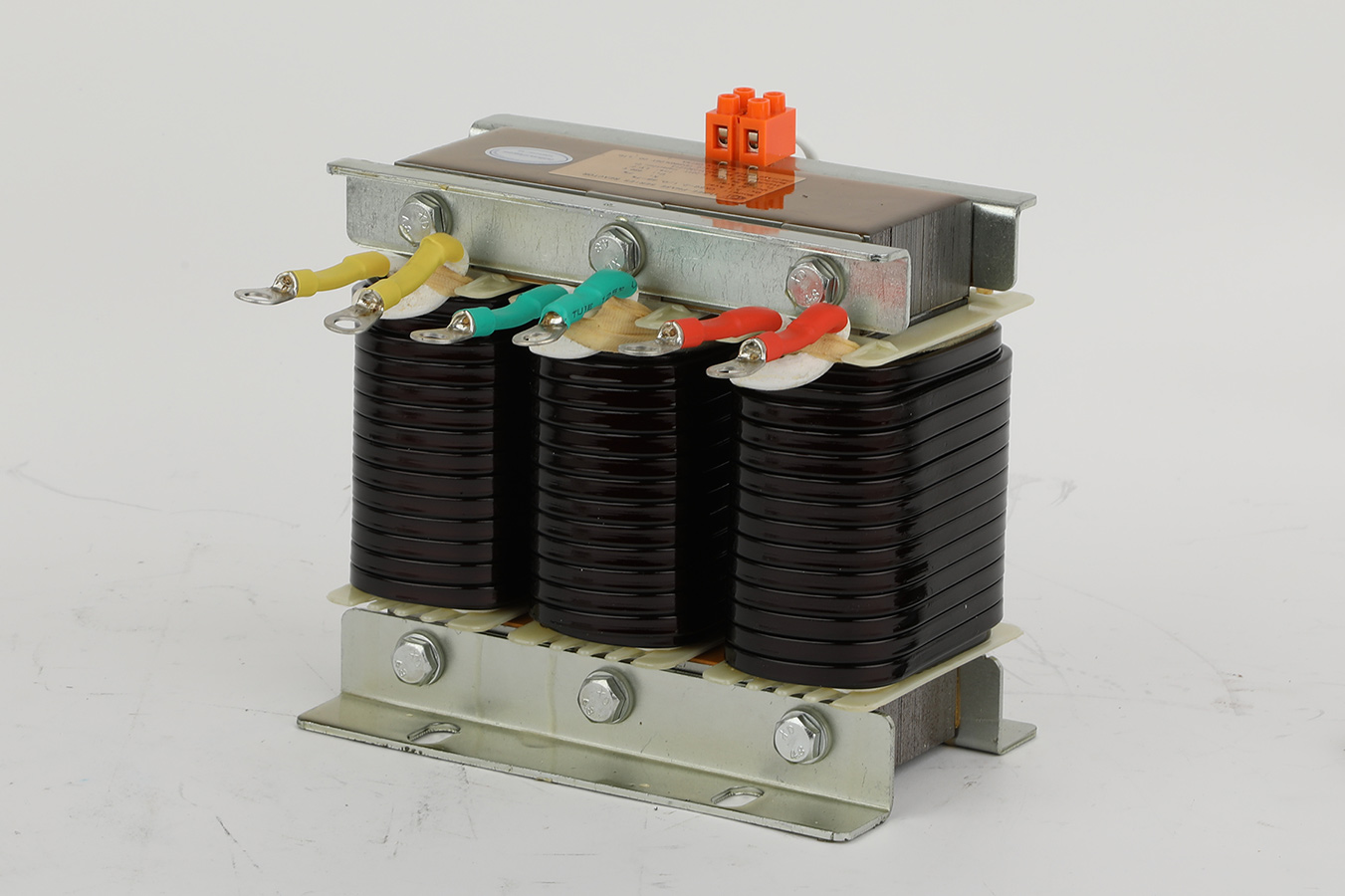

When power is supplied, the electronic switch operates first, connecting the circuit when the current is most stable, and then the mechanical switch engages. This avoids the greatest current surge.

When power is turned off, the sequence is reversed: the electronic switch opens first, and once the current dissipates, the mechanical switch easily opens. This entire process eliminates significant current surges and sparks. This operating method is particularly suitable for applications requiring frequent switching.

Our workshop has conducted experiments and found that when using a composite switch to switch capacitors, the inrush current is less than one-tenth of the original, and the service life of the switch is significantly extended to over 100,000 times. This is undoubtedly good news for users who need to switch capacitors every day.

How We Designed Combination Switches

Reliability and durability are paramount for combination switches. The electronic switch modules we produce undergo rigorous testing to ensure they operate optimally every time. The mechanical switches are made of extremely wear-resistant materials, so they are not easily worn out by daily use.

All components are neatly arranged, heat dissipation is excellent, and maintenance is convenient. Solid wiring terminals can prevent overheating caused by poor contact.

Acctual User Experience

Customer feedback indicates that compound switches are indeed effective. One factory previously had to replace their switches several times a month, but after using our combination switches, they experienced no problems for over six months. Their electricity bills also show that their monthly electricity bills have been reduced by approximately 5% due to the improved voltage stability. Combination switches offer significant advantages in applications where frequent capacitor adjustments are required, such as welding workshops and steel mills. They last even after frequent switching, eliminating the need for frequent repairs. Customers say they no longer have to worry about replacing switches.

We've also found that using compound switches extends the life of capacitors. Because each switching operation is smooth, the impact on the capacitors is reduced, resulting in longer lifespan. This will allow customers to save more costs.

How to maintain

Routine maintenance of a combination switch is actually quite simple. The key is to develop a habit of regular inspections.

Always pay attention to the sound of the switch. Normal operation should produce a crisp click. If the sound becomes dull or noisy, it's time to pay attention. It's best to measure the switch's operating time to see if it's within normal limits. These simple checks can help identify problems early and prevent minor issues from becoming major problems.

Heat dissipation is especially important in hot summer weather. Just like humans need to breathe, switches need good ventilation.

With continuous technological advancements, combination switches will continue to become increasingly intelligent. We are currently developing remote monitoring capabilities that will allow users to check the switch status at any time on their mobile phones. This way, even when away from home, users can monitor the device's operation.

Summary

Combination switches have truly solved the long-standing problem of capacitor switching. Their intelligent switching method is both safe and reliable, making them particularly suitable for applications requiring frequent operation. In actual use, they not only extend the life of the equipment but also help users save energy and money.

- What Exactly is the Boundary Between Static Compensation and Dynamic Compensation in the field of low-voltage reactive power compensation?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for Reactive Power Compensation in Power Systems?

- Can Three Phase Intelligent Low Voltage Compound Switch Achieve Technological Innovation in Reactive Power Compensation of Power Systems?

- Can AC contactors become key actuators in industrial automation control?

- Can Self-healing Shunt Capacitor Become a Key Support for Smart Grid Construction?

- How Can Multifunctional Meter Lead a New Revolution in Energy Management?