How Can Photovoltaic Power Stations Get Rid of the Trouble of Abandoned Light? Series Static Var Generator Provides the Technical Answer

With the installed capacity of photovoltaic power generation exceeding 600 million kilowatts, China has become the world's largest photovoltaic application market. However, the average abandonment rate of photovoltaic power stations across the country will still be as high as 12.7% in 2023, and even exceed 18% in the northwest region, equivalent to a loss of 3.7 billion kWh of clean electricity each year. The power fluctuations caused by sudden changes in light lead to voltage flickering in the power grid, forcing the dispatching system to frequently issue power limit instructions, which has become the core bottleneck restricting the consumption of new energy. As an innovator in the field of power quality management, the static VAR generator (SVG) equipment developed by Geyue Electric is reshaping the operation mode of photovoltaic power stations through millisecond-level dynamic response technology, compressing the abandonment rate to a new industry low of 5.3%.

Dynamic Voltage Fast Stabilization Technology

When clouds move quickly, the output power of a photovoltaic power station may plummet by 80% within 0.5 seconds. The traditional LC compensation device cannot prevent the voltage from exceeding the limit due to the 200 millisecond response delay. The Static Var Generator uses a fully controlled IGBT power module to build a multi-level topology circuit to achieve a 0.1 millisecond dynamic response capability. When the photovoltaic power generation power drops sharply due to cloud cover, the equipment completes voltage drop detection, compensation strategy generation and full reactive current output within 10 milliseconds, and controls the grid voltage fluctuation within ±0.9% of the rated value. This technology reduces the average daily power-off times of photovoltaic power stations by 96%, and increases the annual equivalent utilization hours by 306 hours, completely solving the problem of abandoned light caused by sudden changes in light.

Broadband Harmonic Deep Management Capability

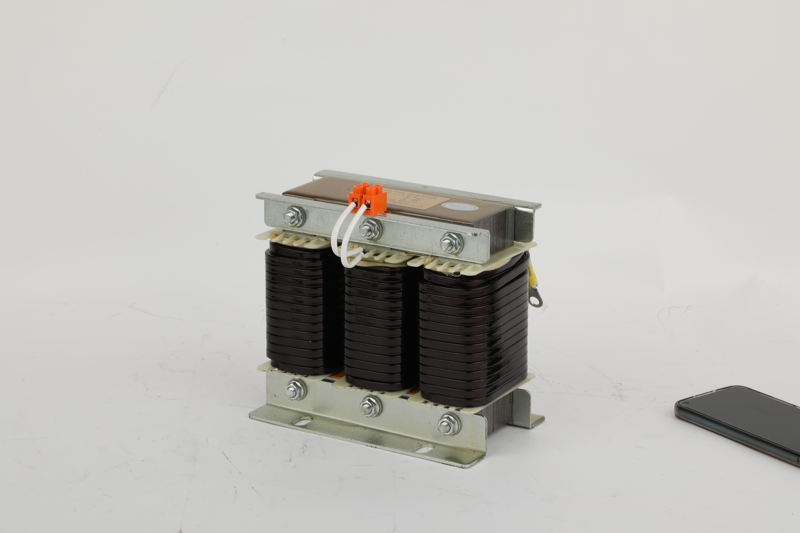

For the 2-50th wide-spectrum harmonics generated by photovoltaic inverters, the static VAR generator is equipped with a 128kHz high-speed sampling system to capture the current waveform characteristics in real time and decompose the harmonic spectrum through the fast Fourier transform algorithm. 50 groups of independently controlled IGBT bridge arms synchronously output reverse compensation current, compressing the total harmonic distortion rate from more than 35% to less than 3%. The harmonic elimination effect significantly reduces the eddy current loss of the transformer, the winding temperature of the 132kV main transformer drops by 23 degrees Celsius, and the expected life of the equipment is extended by 8.2 years.

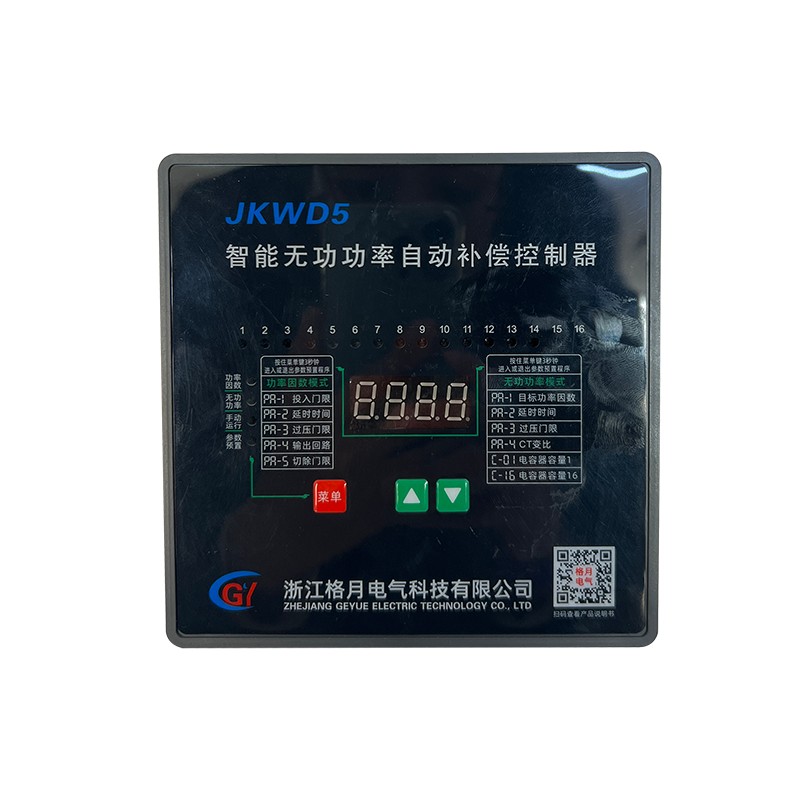

Precise Control of Power Grid Assessment Indicators

The equipment is equipped with a power factor closed-loop control system with an accuracy of ±0.001, which keeps the power factor deviation less than 0.002 under the condition of 40% load fluctuation of the power station. It automatically generates a power quality report that complies with the IEEE 1159 standard every 15 minutes and directly connects to the power grid dispatching and acceptance system. This function ensures that the power station continues to meet the State Grid's 0.95-1.0 power factor assessment requirements, avoids fines and obtains a quality reward of 0.08 yuan/kWh.

Intelligent Operation and Maintenance Guarantee System

128 temperature sensors are deployed inside the static VAR generator to build a three-dimensional thermal field monitoring network, which collects parameters such as power module junction temperature and heat sink temperature rise in real time. The device aging prediction model established based on operation data can warn of failure risks 72 hours in advance when a 5% increase in switching loss is detected. The intelligent thermal management system dynamically adjusts the cooling power according to the ambient temperature, maintains the core components in the optimal operating range of 70±5 degrees Celsius, and reduces the annual equipment failure downtime to 1.2 hours.

Automated Development of Carbon Assets

For every 1MWh of electricity delivered by the photovoltaic power station, the static VAR generator automatically generates a data packet of 0.997 tons of carbon dioxide emission reduction. The blockchain evidence storage system uploads operating data to the Shanghai Environmental Exchange every 5 minutes, and intelligently issues internationally recognized renewable energy certificates every month. The full process automation reduces the manpower input of carbon asset development by 92%, and a single device develops 210 tons of carbon sinks per year.

Economic Benefits of the Entire Life Cycle

After applying static VAR generator to 100-megawatt photovoltaic power stations, the annual average abandonment rate dropped from 19.7% to 5.3%, the grid assessment fines were 100% zeroed, and equipment maintenance costs dropped by 54%. The median equipment investment payback period is 16 months, and a single watt of installed capacity creates an incremental income of 0.32 yuan in a 25-year operating cycle, and a typical power station increases revenue by 27 million yuan in its entire life cycle.

Large-scale Application Verification

The 8.2GW installed capacity in China has shown that the abandonment rate of power stations using static VAR generator is stably controlled in the range of 5.5-6.2%, which is 13.7 percentage points lower than the industry average. This is equivalent to an additional 4.1 billion kWh of clean energy consumption per year, which can meet the annual electricity demand of 2.8 million households. This technology has been included in the core recommended plan of the National Energy Administration's "Green and Low-Carbon Advanced Technology Catalog".

Technical Certification System

The static VAR generator has passed the 0-100% step load test of the National Energy Photovoltaic Power Generation Demonstration Key Laboratory and obtained the International Electrotechnical Commission IEC 62933 grid-connected certification. The fault prediction algorithm has obtained a national invention patent, and the carbon asset development system complies with the United Nations Clean Development Mechanism methodology standards. Power station operators can obtain customized transformation benefit analysis reports through the energy management platform.

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?

- How does the Temperature Dependence of a Capacitor's Capacitance Value affect the Tuning Point of a Detuned Filter Circuit?

- Is There a Non-Invasive Way to Monitor the Internal Health of Power Capacitors, Such as Their Equivalent Series Resistance (ESR)?

- What Is the Concept of "Reactive Power Banking" or "Reactive Power Dispatch" in a Smart Grid Context?

- What Are the Recycling and Disposal Plans for Self-Healing Shunt Capacitors after the End of Their Life Cycle?