How to Choose Energy-Saving and Safe Power Capacitors?

Preface

In a factory's power system, electricity costs are a significant component of operating costs. Reactive power compensation is an effective means of reducing electricity costs and improving power supply quality, and power capacitors are a core component of reactive power compensation. Choosing the right capacitor not only reduces a company's electricity bill immediately but also avoids the risk of production downtime caused by frequent failures. Many customers only focus on price when choosing capacitors, but ignore key technical parameters, which will lead to increased costs in the long run. This article will explain in simple terms the five major parameters that influence capacitor performance and cost.

Why shouldn't capacitor voltage ratings be compromised?

The rated voltage is the most fundamental parameter for power capacitors; it must be higher than the actual system voltage. The standard voltage of my country's low-voltage power grid is 380 volts, but this voltage fluctuates within a certain range, potentially exceeding 400 volts. If a capacitor's rated voltage barely reaches 380 volts, it will be overloaded for extended periods at higher voltages, causing severe internal heat and a drastically shortened lifespan. We always recommend selecting products with a rated voltage of 450V or higher for 380V systems. This extra margin can act as a buffer against voltage fluctuations, thus ensuring safe operation. Incorrect voltage selection is one of the main causes of capacitor bulging, leakage, and even fire.

Is larger capacitor capacity always better?

Compensation capacity must be precisely calculated based on actual power usage; larger is definitely not always better. Insufficient capacity will result in substandard power factor and potential electricity bill penalties. Excessive capacity can lead to overcompensation, feeding reactive power back into the grid, raising voltage and threatening the safety of other equipment.Compensation panels typically utilize multiple switching groups, and the capacity of individual capacitors must be matched to load fluctuations. Common capacities include 10, 15, 20, 25, and 30 kvar. When retrofitting older panels with limited space, high capacity within a compact package is often required. This can be achieved through the use of ultra-thin dielectric materials and optimized internal structure. How do dielectric losses affect my electricity bill? Dielectric loss is a core indicator of power capacitor quality and determines its energy consumption. High-quality capacitors consume very little energy, while low-quality capacitors can be hidden energy hogs. For example, a low-quality 30 kvar capacitor can waste thousands of yuan in electricity bills annually. We use special metallized coatings and purified dielectric materials to keep losses to extremely low levels. This not only saves users money on electricity bills, but also reduces operating temperatures and extends product life. Choosing low-loss capacitors is an investment in future stable operation.

How do we ensure the self-healing capabilities of capacitors?

When a minor internal fault occurs in a capacitor, the self-healing function instantly isolates the fault point, ensuring continued safe operation of the equipment. We use a zinc-aluminum composite coating and high-resistance design to ensure a gentle and reliable self-healing process. Each product undergoes rigorous self-healing testing to ensure it can withstand various emergencies throughout its lifespan. We also equip each power capacitor with a pressure-proof explosion-proof device that quickly disconnects even in extreme conditions, ensuring absolute safety. This dual-protection design provides users with complete peace of mind.

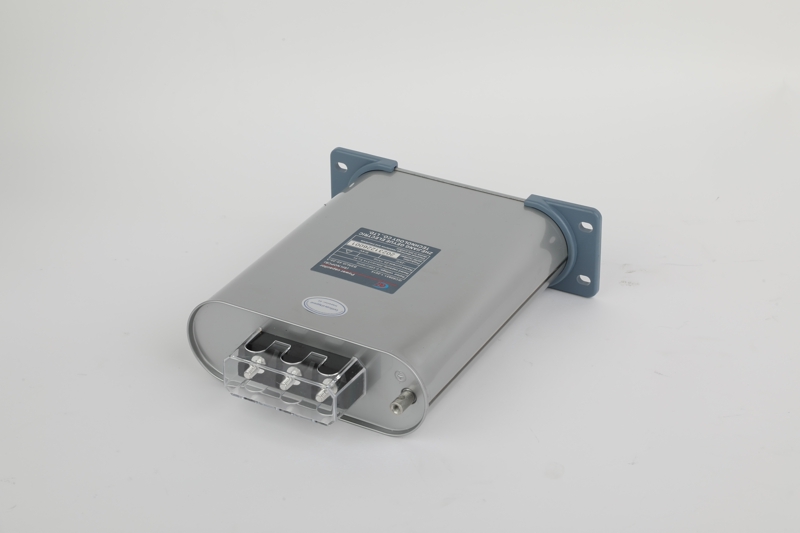

How does the casing material affect the lifespan of a capacitor?

We consistently use cylindrical aluminum alloy housings, a material with excellent thermal conductivity and mechanical strength. The aluminum shell quickly conducts away internal heat, effectively reducing operating temperatures. We've added heat dissipation ribs to the housing surface to further enhance heat dissipation. Testing has shown that this design can reduce surface temperature by 5-8 degrees Celsius, significantly extending product life. The fully sealed structure achieves IP54 protection, effectively resisting dust and moisture, making it suitable for a variety of industrial environments.

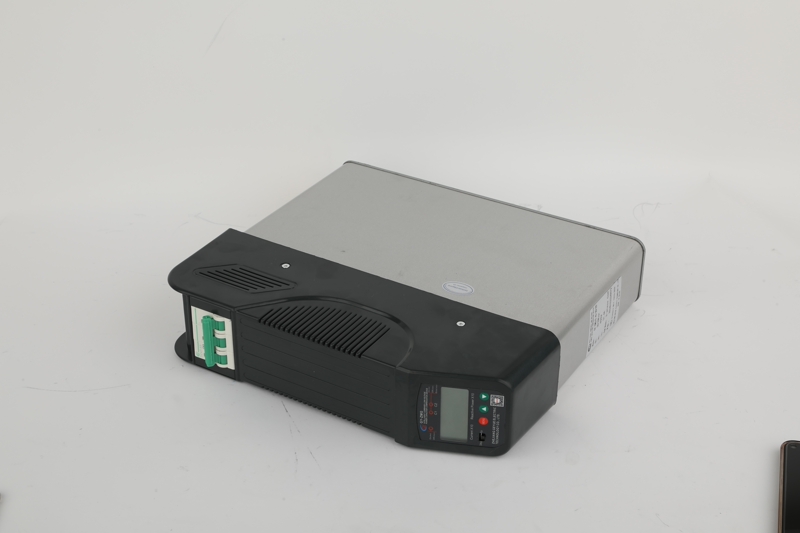

- Can Active Power Filters Become the Key to Solving Power Quality Problems?

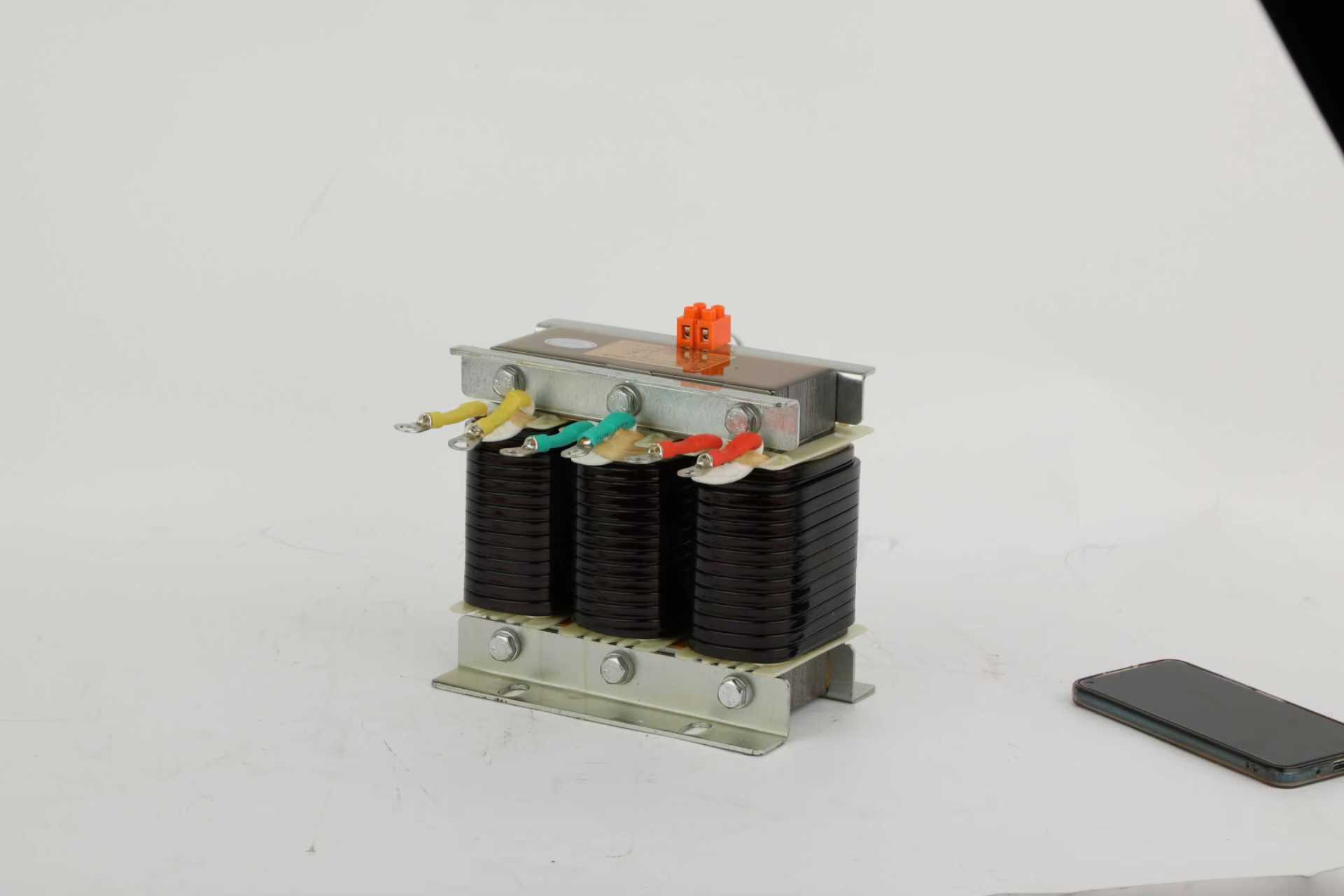

- What Role do Reactors Play in Modern Power Systems?

- Can Capacitor Switches Become Key Equipment in the Smart Grid Era?

- How Has the CJ19 AC Contactor Become a Reliable Choice for Capacitor Switching?

- Can Cylinder Self-healing Shunt Capacitor Become the Ideal Choice for the Smart Grid Era?

- Apart from Saving Electricity Costs, What Value does Low-Voltage Reactive Power Compensation Bring to Enterprises?