News

We are glad to share with you about the results of our work, company news, and give you timely developments and personnel appointment and removal conditions.

06 2025-11

06 2025-11 How Can the Data from Smart Capacitors Be Used for Broader Energy Analytics and Carbon Footprint Reporting?

In the modern industrial energy management field, intelligent capacitors are no longer merely the implementers of reactive power compensation. They are quietly evolving into the data nerve endings of enterprises' energy systems. These seemingly ordinary reactive power compensation devices, by continuously recording their operating status, have opened a door to deep energy cognition and precise carbon footprint management for us. Geyue Electric has deeply understood that leveraging the data from intelligent capacitors will help enterprises gain an advantage in energy conservation and emission reduction as well as sustainable development.

05 2025-11

05 2025-11 What Are the Arc Flash Risks Associated with Capacitor Bank Switching and How Can They Be Mitigated?

Geyue Electric, as a seasoned expert in low-voltage reactive power compensation field, believes that a thorough understanding of the causes of arc flash risks and the establishment of an effective protection system are topics that every power system manager must pay attention to.

04 2025-11

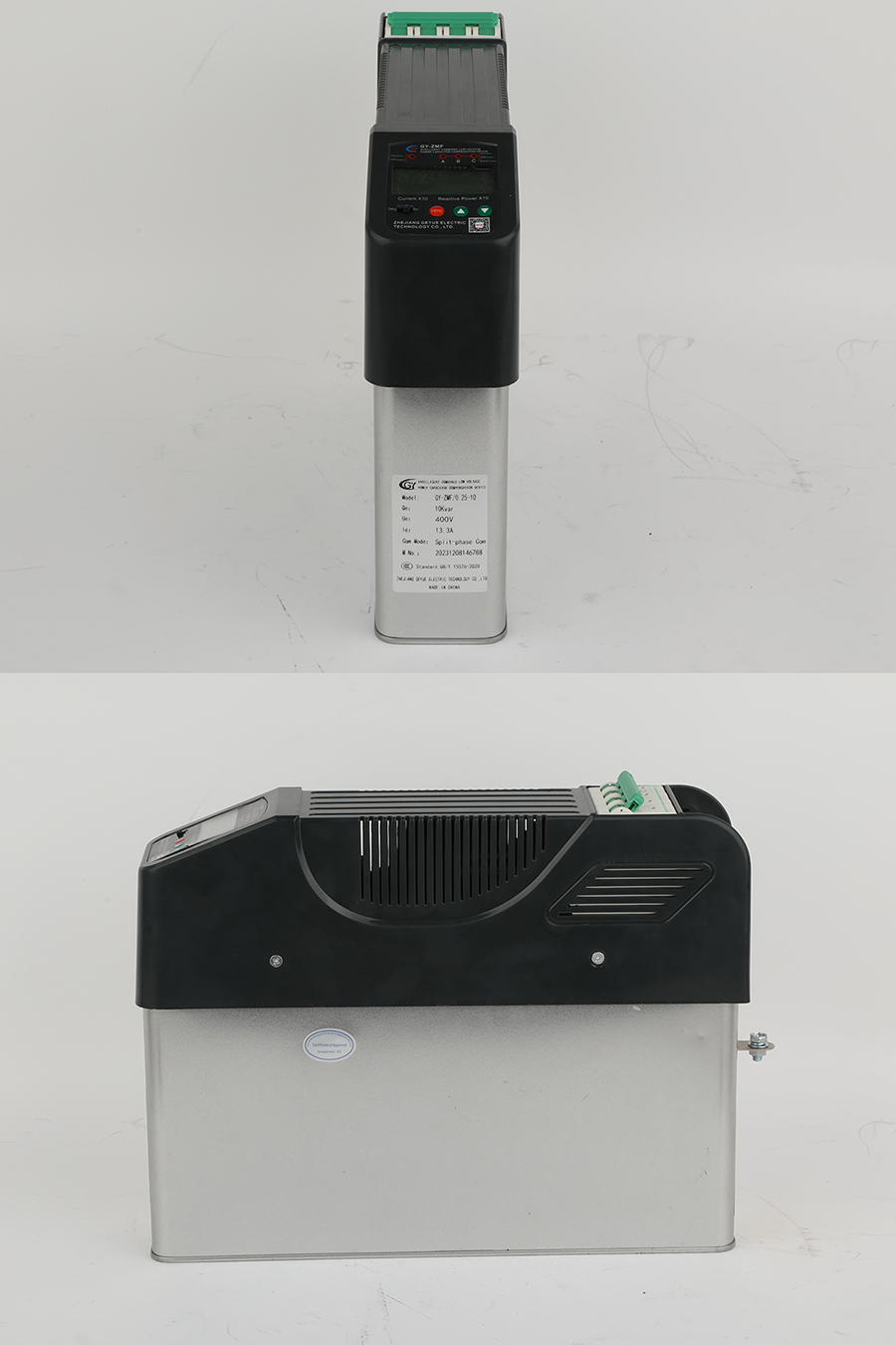

04 2025-11 How do "Smart" Capacitors with Built-in Controllers and Communication Capabilities Differ from Traditional Capacitor modules in a system?

The traditional capacitor modules, with their reliable performance and excellent self-healing characteristics, have long been regarded as the standard components of the reactive power compensation system. However, with the advancement of the industrial Internet of Things and the intelligent trend, an intelligent capacitor that integrates control, protection and communication functions is bringing revolutionary changes to the compensation solution with its unique advantages.

03 2025-11

03 2025-11 What are the Clear Signs That a Capacitor Bank Has Reached Its End-of-Life and Requires Immediate Replacement?

Geyue Electric believes that users of the low-voltage reactive power compensation system can make an accurate judgment of the state of the self-healing shunt capacitors through the following clear signs.

01 2025-11

01 2025-11 What are the Key Performance Indicators for an Anti-Harmonic Capacitor When Operating in a Polluted Environment?

In today's era of rapid industrial development, issues such as harmonic pollution, voltage fluctuations, high temperatures, and high humidity have become inevitable problems that the low-voltage reactive power compensation system must confront.

31 2025-10

31 2025-10 How can Charging Stations Solve Power Quality Problems with the Help of Compensation Cabinets?

This article discusses the pain points of power quality in charging stations, explains the working principle, selection and maintenance of compensation cabinets, and how their application reduces costs and increases efficiency. In the future, they will be upgraded and optimized to meet higher demands.